Hot melt rubber film for adhering metal and non-polar material and preparation method of hot melt rubber film

A non-polar material, hot melt adhesive film technology, used in adhesives, polymer adhesive additives, film/sheet adhesives, etc., can solve the problems of poor adhesion, poor peel strength, degumming, etc. To achieve the effect of lasting and stable bonding, high bonding strength and fast bonding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

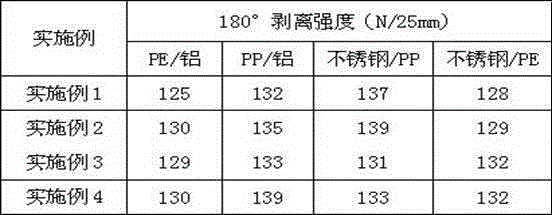

Examples

Embodiment 1

[0031] Preparation of dimer acid type copolyamide: after mixing the dimer acid of 370g, the sebacic acid of 100g, the decanedidiamine of 57g, the hexamethylenediamine of 100g and the caprolactam of 65g, join in a mixer, thermometer and Add 50g of water to the 2L high-pressure reactor with a pressure gauge, replace it with nitrogen and evacuate to remove all the air in the reactor, then fill it with 0.2MPa high-purity nitrogen, heat it slowly to 230°C, at 1.0- Under the pressure of 1.2MPa, heat preservation reaction for 3 hours, slowly reduce the pressure to normal pressure, and continue to reduce the pressure to 0.05MPa for dehydration for 1 hour, discharge and pelletize to obtain granular dimer acid type copolyamide A. According to the national standard GB / T3682-2000, the DSC final melting point of the dimer acid type copolyamide A is 85°C and the melt flow rate is 50g / 10min / 160°C / 2.16kg.

[0032] Preparation of hot-melt adhesive film: 250g of dimer acid type copolyamide A, 3...

Embodiment 2

[0034] Preparation of dimer acid type copolyamide: After mixing 370g of dimer acid, 92.81g of dodecanedioic acid, 34.86g of 2,3-dimethylbutylene diamine, 90g of hexamethylenediamine and 90.27g of caprolactam , into a 2L high-pressure reactor with a stirrer, thermometer and pressure gauge, add 50g of water, replace with nitrogen and vacuumize, remove all the air in the reactor, and then fill it with 0.2MPa high-purity nitrogen , heating slowly to 230°C, under the pressure of 1.0-1.2MPa, heat preservation reaction for 3 hours, slowly reduce the pressure to normal pressure, and continue to depressurize to 0.05MPa for 1 hour, discharge and pelletize to obtain granular Dimer acid type copolyamide B. The DSC final melting point of the dimer acid-type copolyamide B was measured to be 89°C. According to the national standard GB / T3682-2000, the melt flow rate of the dimer acid-type copolyamide B was measured to be 46g / 10min / 160°C / 2.16kg.

[0035]Preparation of hot melt adhesive fi...

Embodiment 3

[0037] Preparation of dimer acid type copolyamide: After mixing the dimer acid of 370g, the adipic acid of 48.28g, the hexamethylenediamine of 73.27g, the 2-methylpentamethylenediamine of 43.96g and the caprolactam of 73g, join in a belt In the high-pressure reaction kettle with agitator, thermometer and pressure gauge, add 50g of water, replace with nitrogen and evacuate, remove the air in the reaction kettle, then charge high-purity nitrogen of 0.2MPa, and heat up slowly to 230 ℃, under the pressure of 1.0-1.2MPa, heat preservation reaction for 3 hours, slowly reduce the pressure to normal pressure, and continue to depressurize to 0.05MPa after dehydration for 1 hour, discharge and pelletize to obtain granular dimer acid type copolyamide c. The DSC final melting point of the dimer acid-type copolyamide C was measured to be 85.5°C. According to the national standard GB / T3682-2000, the melt flow rate of the dimer acid-type copolyamide C was measured to be 48g / 10min / 160°C / 2.16k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com