AC (alternate current) servo motor based on position feedback structure

An AC servo motor and machine tool technology, applied in the direction of a single motor speed/torque control, electronic commutator, etc., can solve the problems of not meeting the positioning accuracy, speeding up the wear of the transmission device, and inaccurate position positioning, and achieving a small tracking error. , Easy to set, improve the effect of position control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

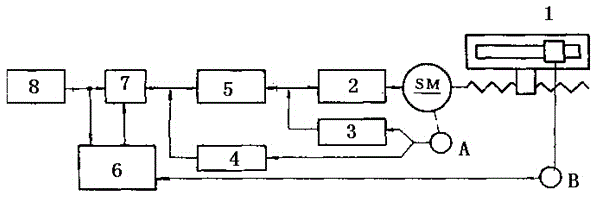

[0017] Such as figure 1As shown, the crankshaft of the AC servo motor SM based on the position feedback structure of the present invention is directly connected to the lead screw of the machine tool workbench 1, and the rotation of the crankshaft of the AC servo motor SM drives the lead screw of the machine tool workbench 1 to move. This forms the movement of the machine tool table 1; the speed and position detection device A is coaxially connected with the AC servo motor SM, and the speed and position detection device A includes a speed detector and a position detector, wherein the position detector directly detects the AC servo motor SM The angular displacement of the crankshaft rotation; the speed detector adopts a tachogenerator or a pulse encoder or a high-resolution photoelectric encoder; the detection signal of the speed detector is fed back to the speed servo mechanism 2 through the speed feedback device 3; the detection of the position detector The signal is fed back ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com