LED (Light Emitting Diode) project lamp intelligent illumination control system

An intelligent lighting control and LED flood light technology, applied in the field of lighting, can solve the problems of reduced forward current, increased light decay of LED chips, and increased maintenance and use costs, so as to improve reliability and life, improve working environment temperature, The effect of reducing the chance of repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

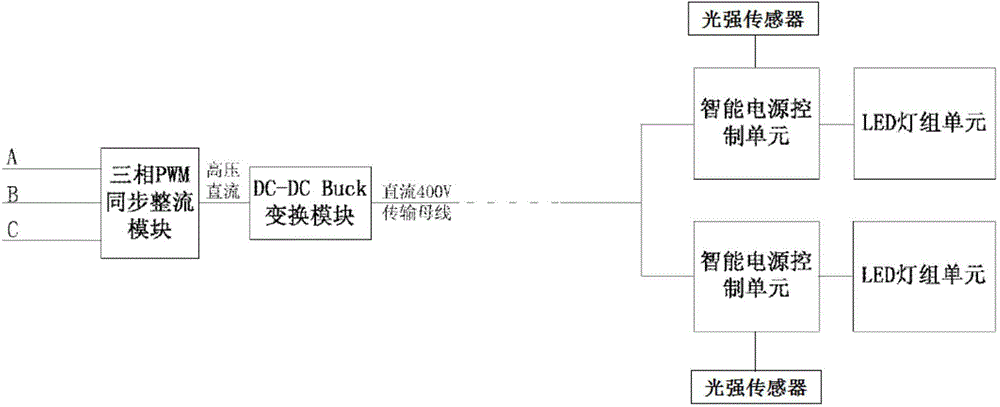

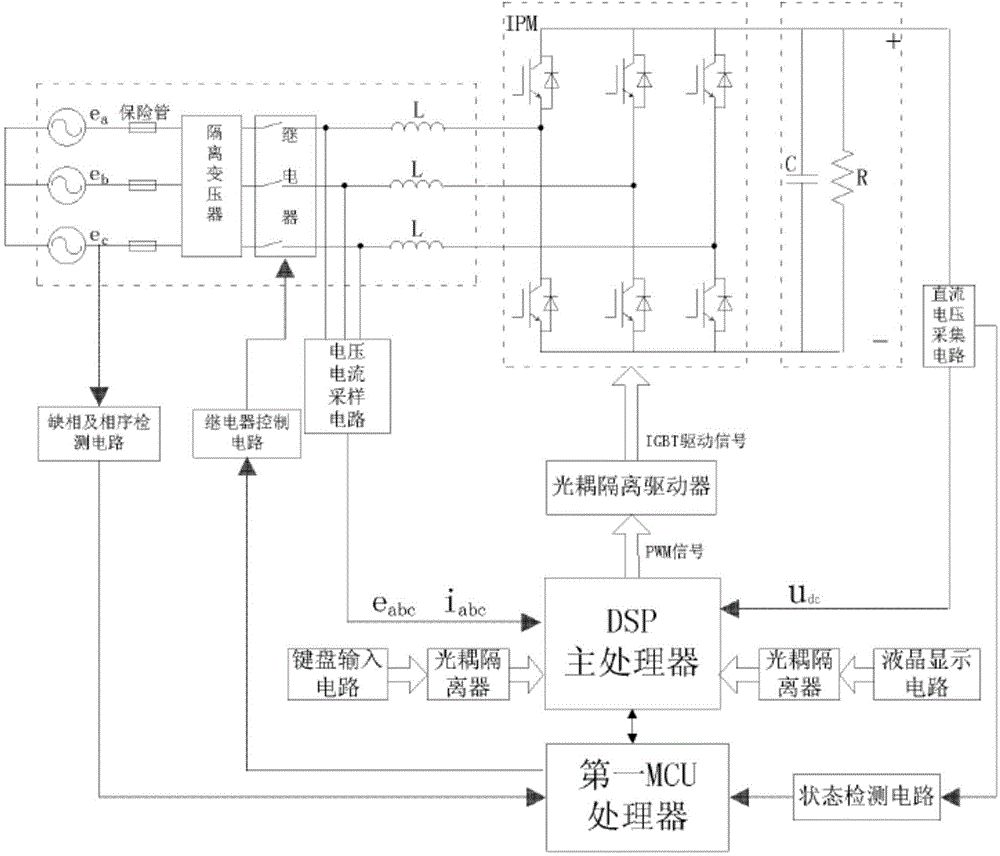

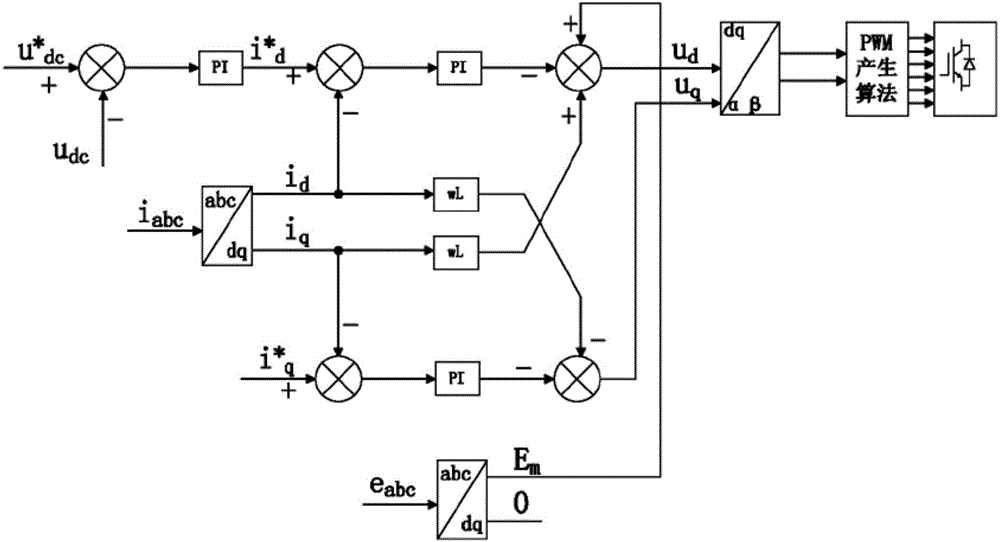

[0030] see Figure 1-12 , an intelligent lighting control system for LED floodlights, including a synchronous rectification unit for providing DC power to at least two intelligent power control units, and a light intensity sensor for providing light intensity information for the intelligent power control units, the light intensity sensor Connect the intelligent power control unit, the output end of each intelligent power control unit is connected to the corresponding LED light group unit through the wire, the synchronous rectification unit is connected to the intelligent power control unit through each high-voltage DC bus, and the multi-intelligent power control unit is provided by the synchronous rectification unit Constant voltage direct current, and each intelligent power supply control unit completes the drive control and detection of its corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com