Method for preparing high-activity Pd nano particle-supported carbon catalyst by diglycol reduction process

A nano-catalyst, diethylene glycol technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the reduction of catalyst dispersion, catalytic activity and stability. , reduce the catalytic efficiency and surface activity of the catalyst, the uneven distribution of Pd nanoparticles, and achieve the effect of inhibiting mutual aggregation, small particle size, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

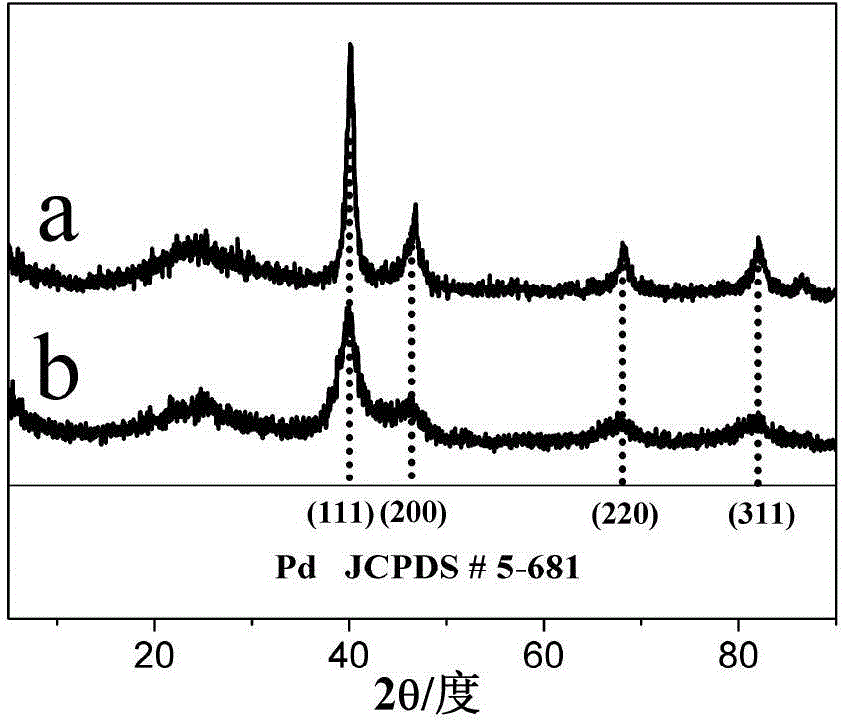

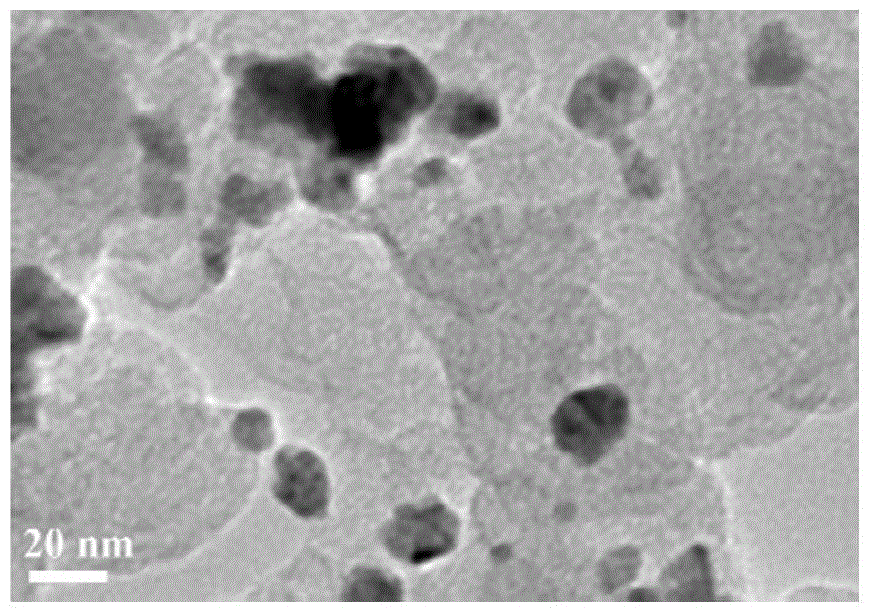

[0020] Weigh 10 mg of Vulan XC-72R activated carbon from Cabot Company, add it to 9 mL of diethylene glycol, oscillate ultrasonically for 3 to 5 minutes, then add 1.2 mg of palladium acetate, after ultrasonic dissolution, stir mechanically at 80 °C for 3 hours, and centrifuge, The obtained precipitate was dried in a vacuum drying oven at 60° C. to obtain a Pd / C catalyst, and the loading amount of metal Pd in the catalyst was 10 wt.%.

Embodiment 2

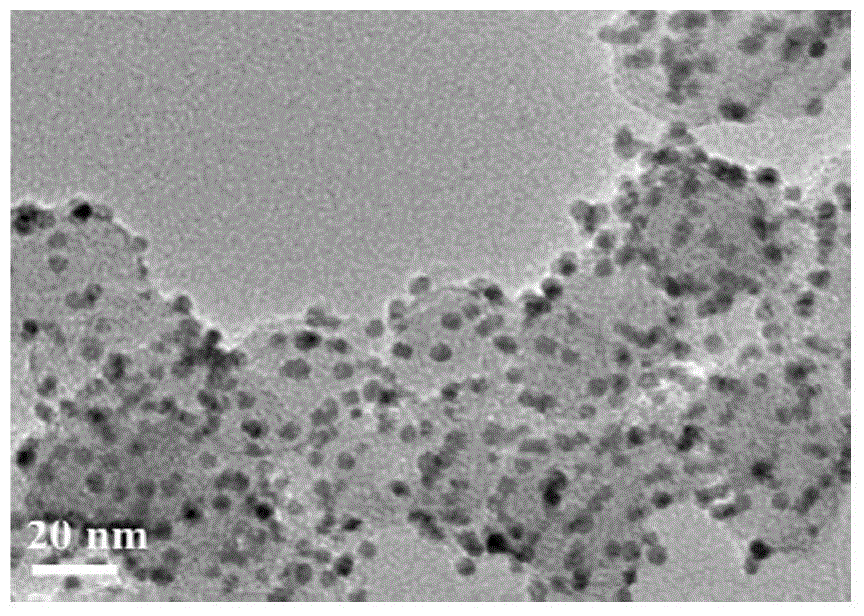

[0025] Weigh 10 mg of Vulan XC-72R activated carbon from Cabot Company, add it to 9 mL of diethylene glycol, oscillate ultrasonically for 3 to 5 minutes, then add 1.2 mg of palladium acetate, after ultrasonic dissolution, mechanically stir at 70 ° C for 4 hours, centrifuge, The obtained precipitate was dried in a vacuum drying oven at 60° C. to obtain a Pd / C catalyst. The loading amount of metal Pd in the catalyst was 10 wt.%, and the metal Pd particles were evenly dispersed, with an average particle diameter of 3-5 nm.

Embodiment 3

[0027] Weigh 10 mg of Vulan XC-72R activated carbon from Cabot Company, add it to 9 mL of diethylene glycol, oscillate ultrasonically for 3 to 5 minutes, then add 1.2 mg of palladium acetate, after ultrasonic dissolution, mechanically stir at 90°C for 2 hours, and centrifuge, The obtained precipitate was dried in a vacuum drying oven at 60° C. to obtain a Pd / C catalyst. The loading amount of metal Pd in the catalyst was 10 wt.%, and the metal Pd particles were evenly dispersed, with an average particle diameter of 3-5 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com