Opoka-base carbon composite material and preparation method thereof

An opal shale and carbon composite material technology, applied in the field of mineral materials, can solve problems such as increasing the cost of hydrothermal carbonization, and achieve the effects of low cost, excellent adsorption performance, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

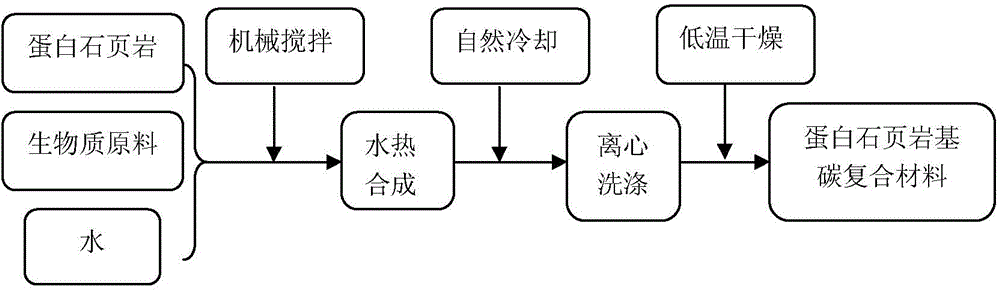

[0028] A method for preparing an opal shale-based carbon composite material, comprising the following steps:

[0029] a. The opal shale raw ore is crushed to 2 mixture;

[0030] b. The powder obtained after grinding the purified opal shale to <100 mesh can be used directly, or the powder can be calcined in a muffle furnace at 300-1000°C for 2-4 hours for thermal activation treatment to improve the surface activity of opal ;

[0031] c. Slurry preparation: disperse opal shale powder and water-soluble biomass carbon source in water at a mass ratio of 20-0.3, the mass ratio of opal shale to water is 0.005-0.15, and mechanically stir for 2-4 hours to form a slurry material;

[0032] d. Transfer the mixed slurry to a hydrothermal reaction kettle, and hydrothermally carbonize at 150-300°C for 4-72 hours;

[0033] e. After natural cooling, open the reaction kettle, centrifugally wash until neutral, and dry at 60-80°C to obtain an opal shale-based carbon composite material.

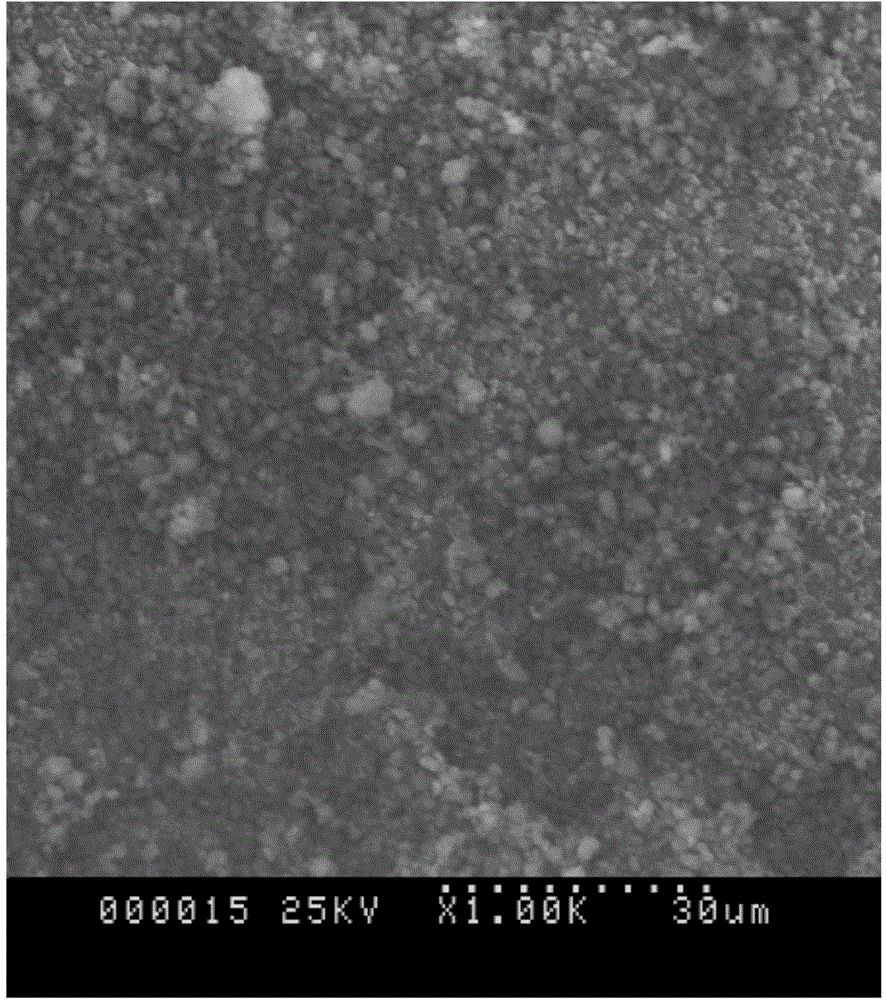

Embodiment 1

[0035] Crush the raw opal shale to 100 mesh, add water to make a suspension with a solid content of 20%, stir mechanically for 2 hours, settle naturally at room temperature for 1 minute, collect the upper liquid, wash and dry it by centrifugation, and complete the purification process of opal shale. Take 2g of the purified opal shale, grind it to <120 mesh, transfer it into a beaker, add 8g of sucrose and 30ml of water, and stir it vigorously for 4 hours to form a slurry. Transfer the slurry to a reaction kettle lined with tetrafluoroethylene, first raise the temperature to 180°C, keep the temperature constant for 30 minutes, then continue to raise the temperature to 200°C, keep the temperature for 14 hours, then take out the reaction kettle to cool naturally. Open the reaction kettle, remove the dry hard oil film in the upper layer of the mixed solution, centrifuge and wash to neutral, wash and centrifuge with absolute ethanol 3 times, dry at 60°C, and after cooling, the opal ...

Embodiment 2

[0038] Crush the raw opal shale to 100 mesh, add water to make a suspension with a solid content of 20%, stir mechanically for 2 hours, settle naturally at room temperature for 1 minute, collect the upper liquid, wash and dry it by centrifugation, and complete the purification process of opal shale. After the purified opal shale is ground, it is placed in a muffle furnace for calcination at 500° C. for 2 hours to obtain heat-activated opal shale powder. Weigh 0.5g of heat-activated opal shale powder, add 2g of glucose and 80ml of water, and stir vigorously for 2 hours to form a slurry. Transfer the slurry to a reaction kettle lined with tetrafluoroethylene, first raise the temperature to 160°C, keep the temperature constant for 30 minutes, then continue to raise the temperature to 180°C, and keep the temperature constant for 6 hours, then take out the reaction kettle and let it cool naturally. Open the reaction kettle, remove the dry and hard oil film in the upper layer of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com