Enterobacter ludwigii and application thereof

A technology of Enterobacter reuteri and MY271, applied in the field of microbiology, can solve the problems of unreported β-mannanase, etc., and achieve the effects of lowering cholesterol levels, improving biological regulation functions, and promoting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the crude enzyme liquid is as follows: take a certain volume of bacterial liquid in a centrifuge tube, centrifuge at 8000rpm for 15 minutes to get the supernatant, and dilute it by an appropriate multiple to obtain the crude enzyme liquid.

[0034] The method for measuring the enzyme activity of β-mannanase is as follows: take 1.5mL of 0.5% konjac purified powder solution in a 25mL colorimetric tube, add 0.5mL of crude enzyme solution and react in a water bath at 55°C for 10min, add 3mL of DNS solution, and place in a boiling water bath After boiling in medium for 5 minutes, cool to room temperature immediately, add distilled water to make up to 25mL, this is the experimental group; the control group uses the boiled inactivated enzyme solution instead of the crude enzyme solution. Absorbance was measured at 540 nm.

Embodiment 1

[0035] Example 1: Optimization of culture conditions for Enterobacter reuteri MY271

[0036] (1) Strain: Enterobacter reuteri MY271CCTCC M 2015182

[0037](2) Method steps:

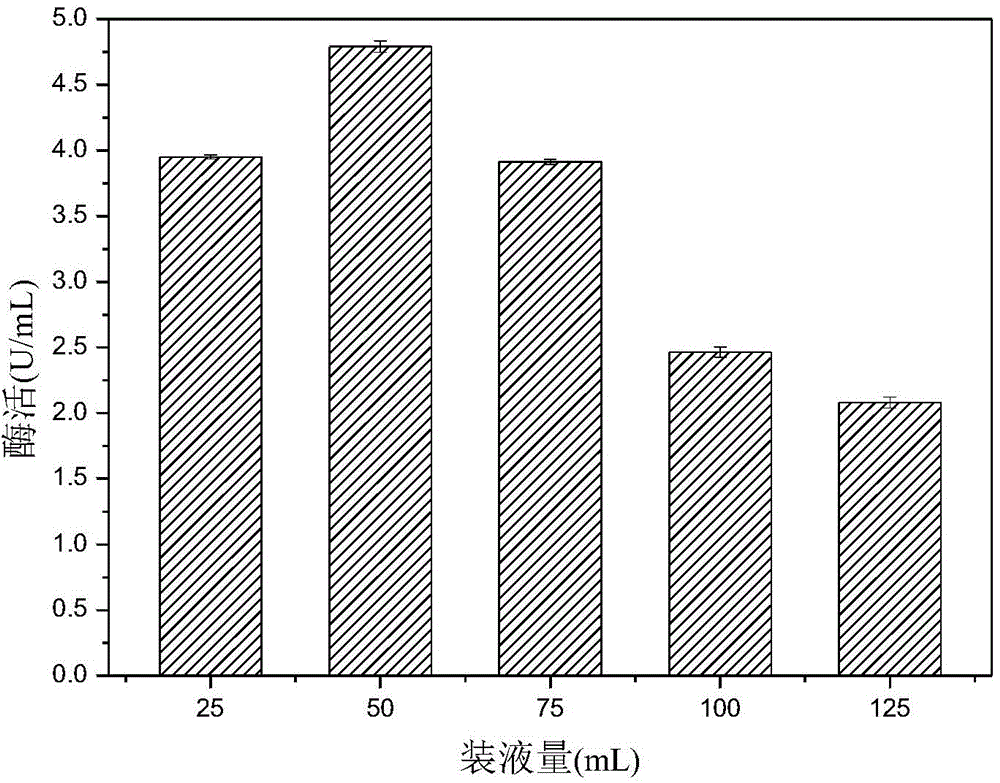

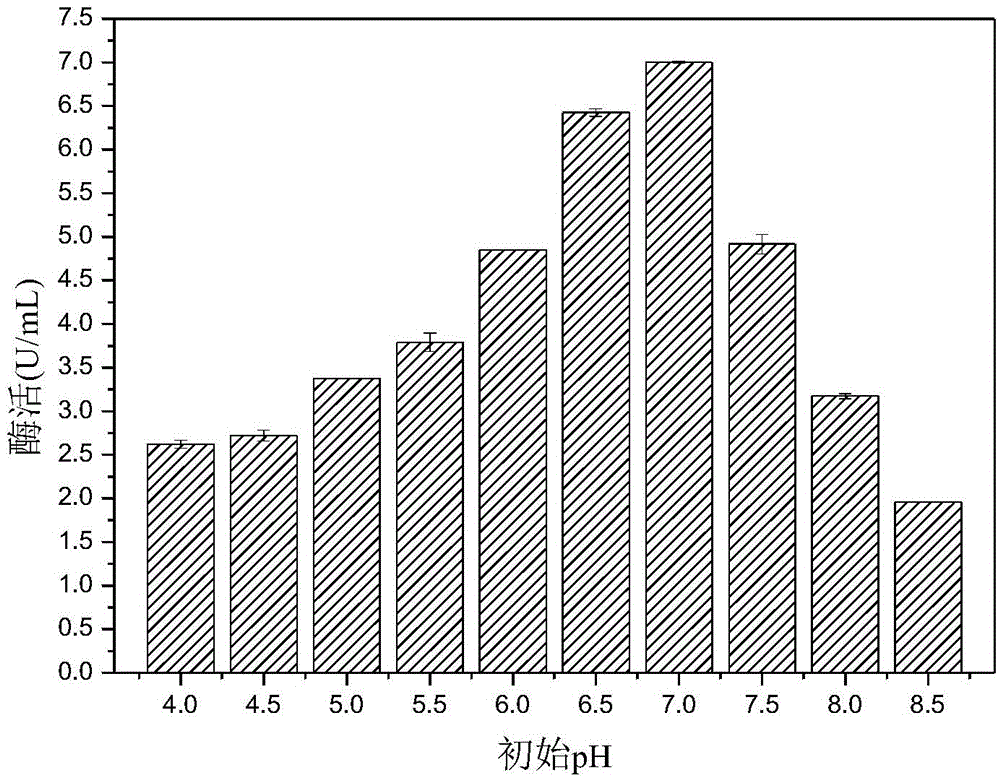

[0038] The fermentation medium was the initial medium (konjac flour 5.0g / L, peptone 5.0g / L, KH 2 PO 4 1.0g / L, MgSO 4 0.1g / L). The initial fermentation conditions are: natural pH, 5% inoculum size, 50mL / 250mL liquid volume, 30°C, 160r / min shake flask fermentation for 48h.

[0039] The single factor experiment was used to investigate the effects of the inoculum amount, liquid volume, initial pH, fermentation temperature and fermentation cycle of Enterobacter reuteri MY271 strain on the production of β-mannanase.

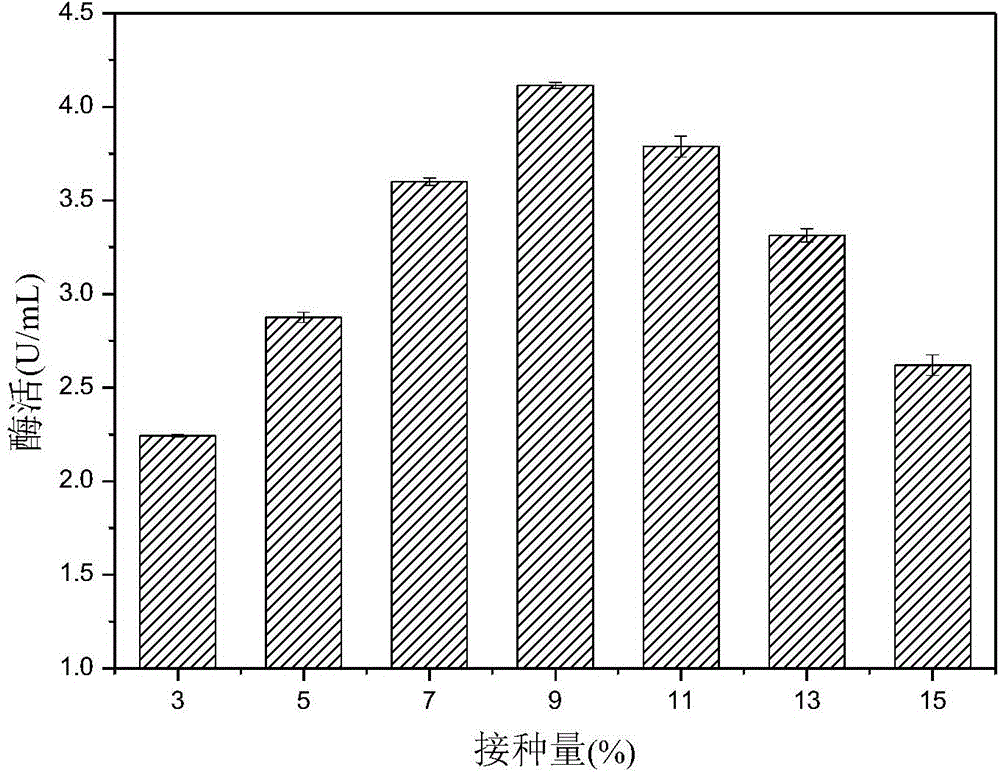

[0040] a. Optimization test of inoculum size

[0041] Other fermentation conditions are the initial fermentation conditions. When the inoculum size is 3%, 5%, 7%, 9%, 11%, 13% and 15%, the effect of the inoculum size on the production of β-mannanase by Enterobacter reuteri MY271 is investi...

Embodiment 2

[0055] Example 2: Optimization of medium components for Enterobacter reuteri MY271

[0056] (1) Bacterial strain: the bacterial species Enterobacter reuteri MY271 screened out in Example 1

[0057] (2) Method steps:

[0058] The culture conditions are fermentation time 4h, temperature 31°C, inoculum size 9%, initial pH 7.0, liquid volume 50mL / 250mL.

[0059] a. Carbon source selection and addition test

[0060] Konjac powder, locust bean gum, sucrose, D-mannose, D-mannitol, soluble starch, maltose, glucose, D-fructose, α-lactose, sodium carboxymethylcellulose, D-xylose, molasses as carbon Source variable, the addition amount is 5g / L, and other components are initial medium components.

[0061] Depend on Figure 6 It can be seen that when konjac flour was used as the carbon source, strain MY271 had the best effect of inducing enzyme production, and the enzyme activity was 8.01 U / mL, followed by locust bean gum. Therefore, konjac flour was selected as the best carbon source....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com