Corrosion liquid of InAsSb/AlAsSb infrared detector and manufacturing method of InAsSb/AlAsSb infrared detector

A technology of infrared detectors and manufacturing methods, which is applied in the manufacturing of semiconductor devices, electrical components, and final products, etc., can solve the problems of expensive investment in dry etching process equipment, achieve high yield, appropriate corrosion speed, reduce dependence and The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0031] A kind of corrosion solution of InAsSb / AlAsSb material infrared detection device, this corrosion solution is made of nitric acid HNO 3 , hydrogen peroxide H 2 o 2 and water H 2 O formulated, the ratio is HNO 3 :H 2 o 2 :H 2 O=1:1:4.

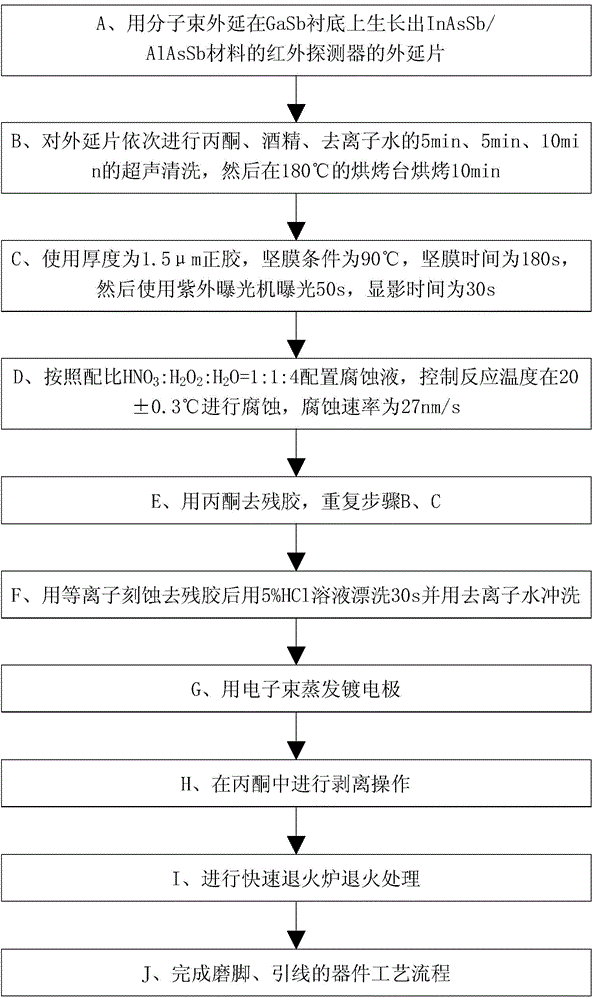

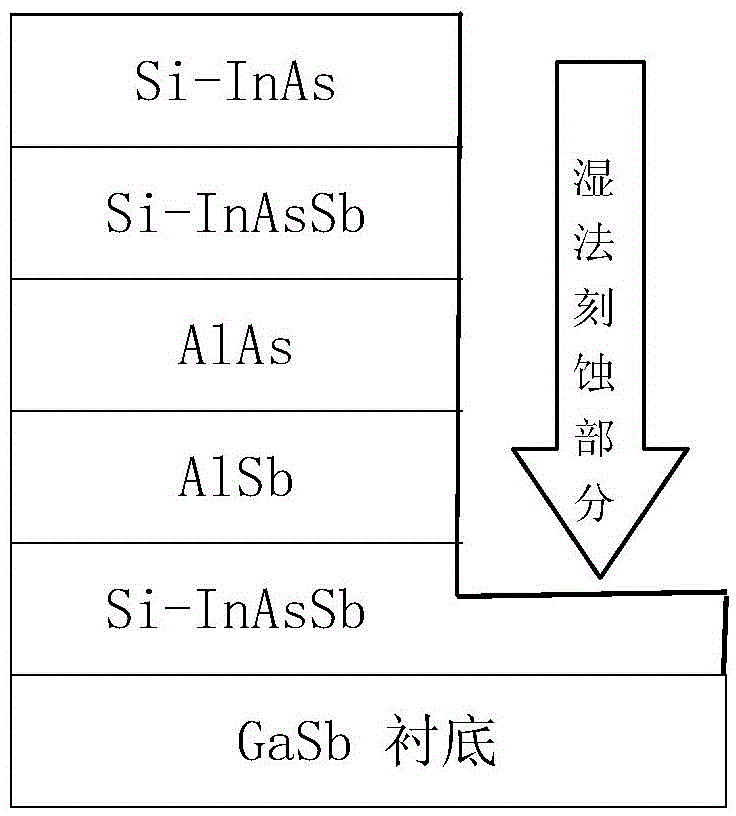

[0032] refer to figure 1 , a method for manufacturing an InAsSb / AlAsSb material infrared detection device, comprising the following steps:

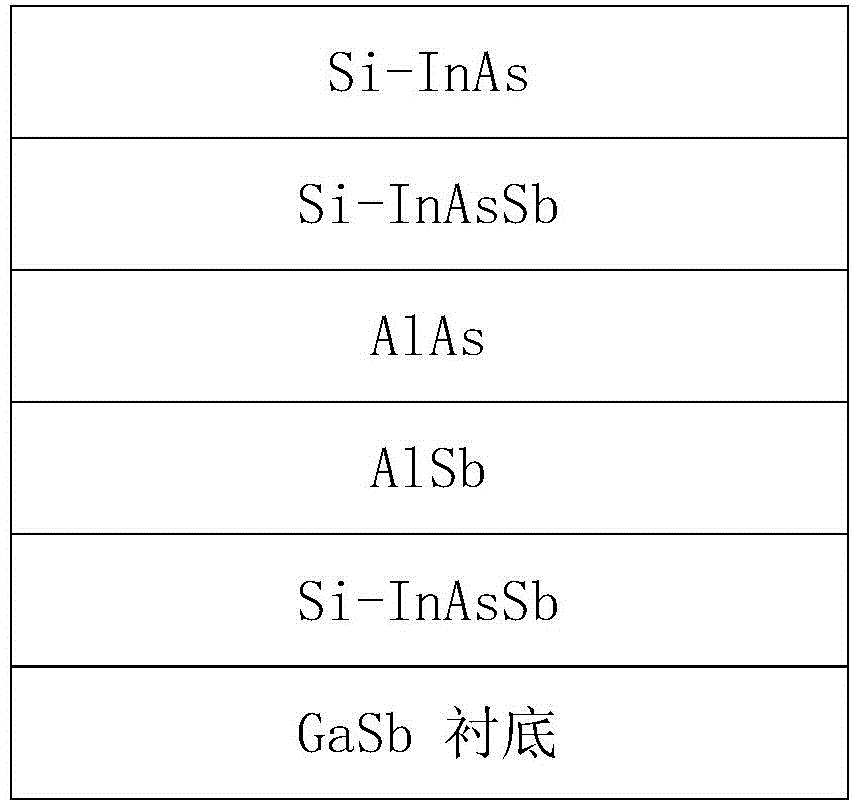

[0033] A. Using molecular beam epitaxy (MBE, Molecular Beam Epitaxy) to grow epitaxial wafers of infrared detectors made of InAsSb / AlAsSb materials on GaSb substrates;

[0034] B. Ultrasonic cleaning of epitaxial wafers with acetone, alcohol, and deionized water for 5 minutes, 5 minutes, and 10 minutes in sequence, and then baked on a baking table at 180°C for 10 minutes;

[0035] C. Use a positive resist with a thickness of 1.5 μm, the hardening condition is 90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com