Method for preparing nano-patterns based on laser interferometric lithography

A laser interference lithography, nano-patterning technology, applied in nanotechnology, opto-mechanical equipment, optics, etc., can solve the problems of increasing exposure dose and high cost, avoiding standing wave effect, good industrialization, and reducing cost effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

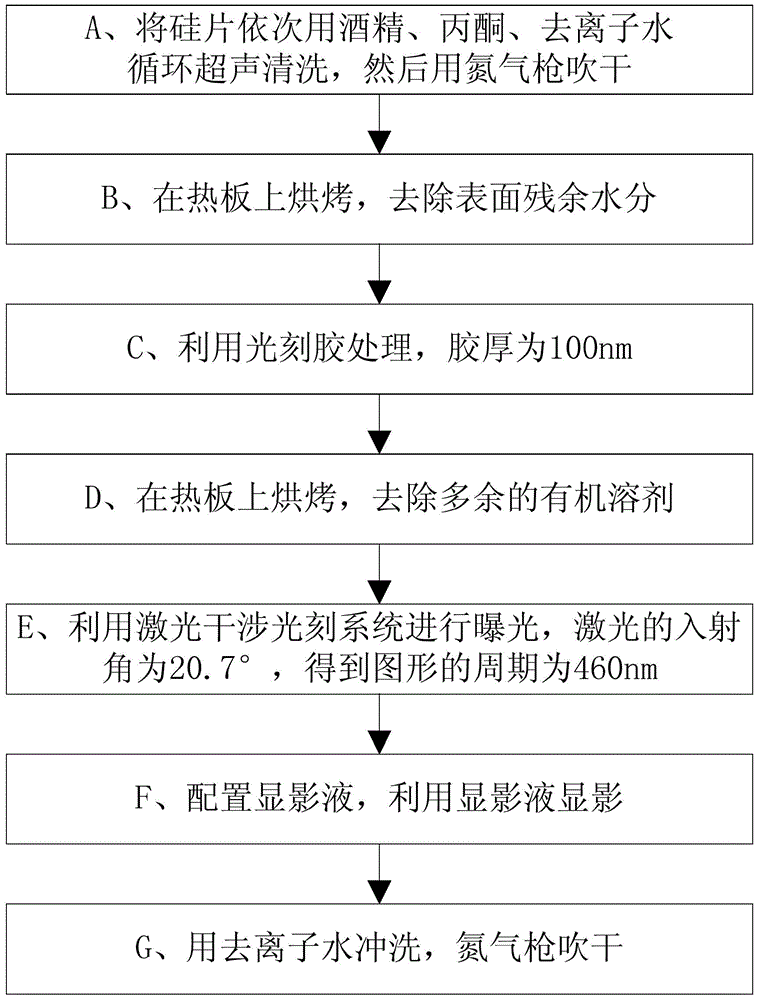

[0034] refer to figure 1 , a method for preparing nano-patterns based on laser interference lithography, comprising the following steps:

[0035] A. Clean the silicon wafer sequentially with alcohol, acetone, and deionized water, and then dry it with a nitrogen gun;

[0036] B. Bake on a hot plate to remove residual moisture on the surface;

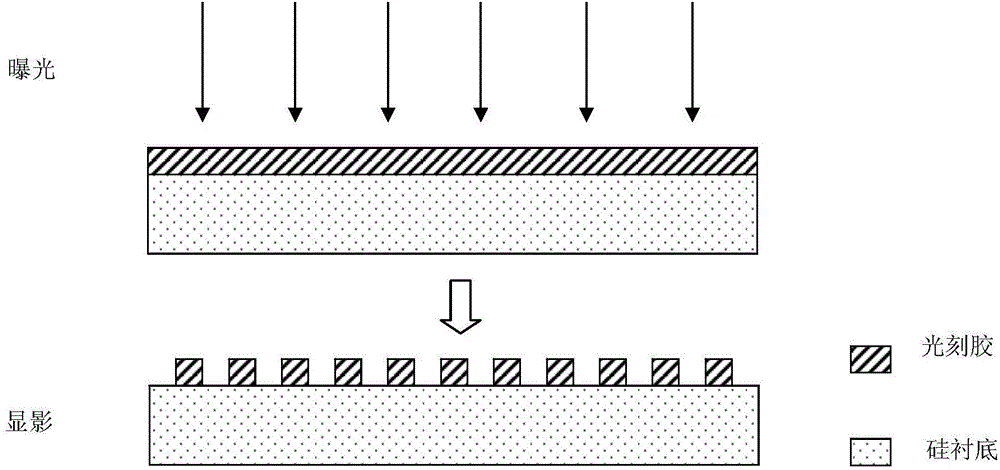

[0037] C, using photoresist treatment, the thickness of the glue is 100nm;

[0038] D. Bake on a hot plate to remove excess organic solvent;

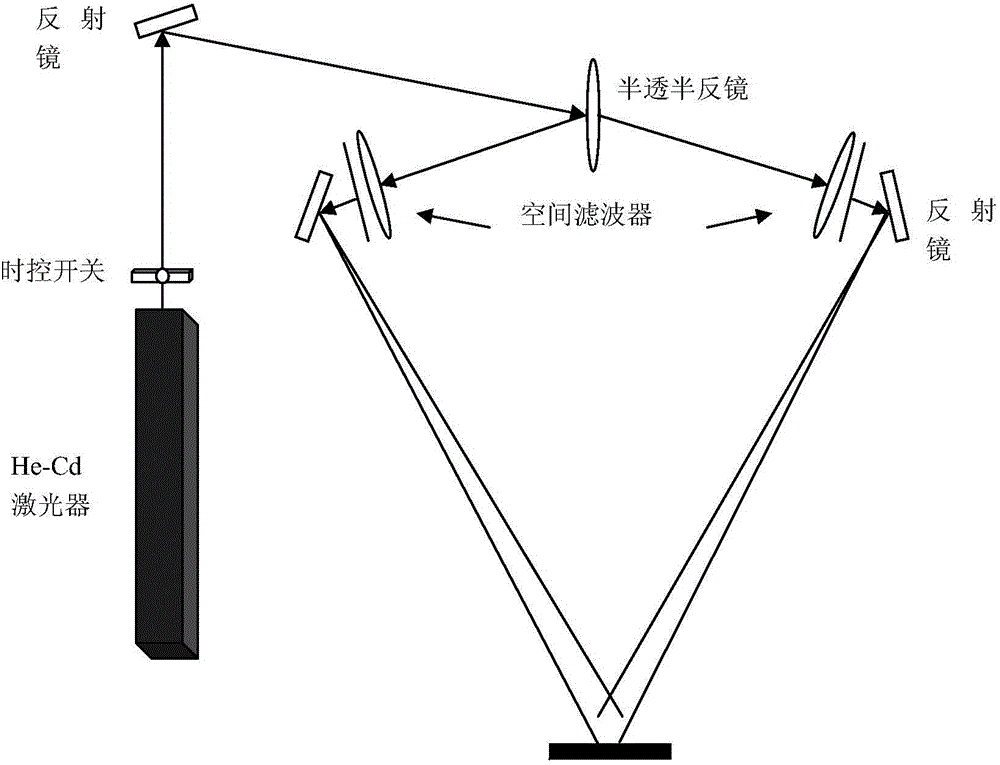

[0039] E. Expose by laser interference lithography system, the incident angle of the laser is 20.7°, and the period of the obtained pattern is 460nm;

[0040] F, configure developing solution, utilize developing solution to develop;

[0041] G. Rinse with deionized water and dry with a nitrogen gun.

[0042] As a further preferred embodiment, in the above step A,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com