Method for preparing high-conductivity stretchable sponge graphene-based electrode material

A graphene-based electrode material technology is applied in the preparation of stretchable materials and the preparation of highly conductive sponge-like graphene-based electrode materials, and can solve the problems of difficulty in stretching, high resistance, insufficient tensile stability, and the like, To achieve the effect of good conductivity, high application value, simple and controllable method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

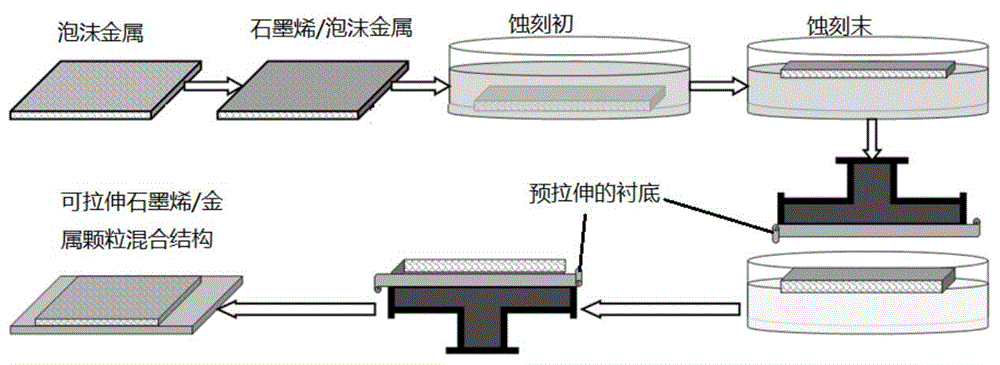

[0034] Growth of graphene on foamed nickel substrates and eventually growth of graphene / nickel particle hybrid structures, such as figure 1 The preparation roadmap includes the following preparation steps:

[0035] 1. Take nickel foam with a size of 8cm×8cm and place it in a tube furnace;

[0036] 2. Turn on the vacuum pump to pump the air pressure of the tube furnace to the ultimate vacuum state of 3×10 -6 Torr;

[0037] 3. Keep vacuum 3×10 -6 After Torr for 15 minutes (the effect of vacuum for 15 minutes is to remove impurities, air, etc. inside the quartz tube to ensure that the reaction chamber is clean), the air pressure of the quartz tube 3 is raised to 3 × 10 -3 Torr;

[0038] 4. Set the hydrogen flow meter to 100sccm, and inject hydrogen into the vacuum chamber;

[0039] 5. After the tube furnace temperature rises to 300°C, anneal at a constant temperature for 20 minutes;

[0040] 6. After the tube furnace temperature rises to 1000°C, inject methane into the vacu...

Embodiment 2

[0059] Growth of graphene on foamed copper substrates and eventually growth of graphene / copper particle hybrid structures, such as figure 1 The preparation roadmap includes the following preparation steps:

[0060] 1. Take foam copper with a size of 8cm×9cm and place it in a tube furnace;

[0061] 2. Turn on the vacuum pump to pump the air pressure of the tube furnace to the ultimate vacuum state of 3×10 -6 Torr;

[0062] 3. Keep vacuum 3×10 -6 After Torr for 15 minutes (the effect of vacuum for 15 minutes is to remove impurities, air, etc. inside the quartz tube to ensure that the reaction chamber is clean), the air pressure of the quartz tube 3 is raised to 3 × 10 -3 Torr;

[0063] 4. Set the hydrogen flow meter to 100sccm, and inject hydrogen into the vacuum chamber;

[0064] 5. After the tube furnace temperature rises to 300°C, anneal at a constant temperature for 20 minutes;

[0065] 6. After the tube furnace temperature rises to 1000°C, inject methane into the vacu...

Embodiment 3

[0084] Growth of graphene on foamed nickel substrates and eventually growth of graphene / nickel particle hybrid structures, such as figure 1 The preparation roadmap includes the following preparation steps:

[0085] 1. Take nickel foam with a size of 5cm×9cm and place it in a tube furnace;

[0086] 2. Turn on the vacuum pump to pump the air pressure of the tube furnace to the ultimate vacuum state of 3×10 -6 Torr;

[0087] 3. Keep vacuum 3×10 -6 After Torr for 15 minutes (the effect of vacuum for 15 minutes is to remove impurities, air, etc. inside the quartz tube to ensure that the reaction chamber is clean), the air pressure of the quartz tube 3 is raised to 3 × 10 -3 Torr;

[0088] 4. Set the hydrogen flow meter to 100sccm, and inject hydrogen into the vacuum chamber;

[0089] 5. After the tube furnace temperature rises to 300°C, anneal at a constant temperature for 20 minutes;

[0090] 6. After the tube furnace temperature rises to 1000°C, inject methane into the vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com