Method for growing graphene in silicon micro-channel plate

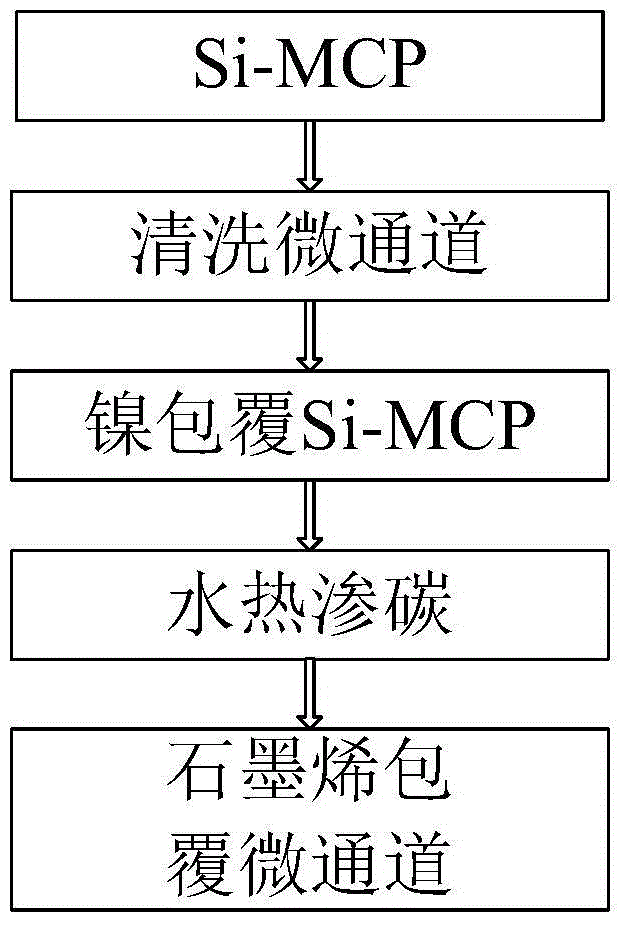

A silicon microchannel plate and graphene technology, applied in the field of microelectromechanical systems, can solve the problems of expensive equipment, difficult process, difficult industrialization, etc., and achieve the effects of low cost, avoiding complex processes and being environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] One method of growing graphene in a microchannel plate is as follows:

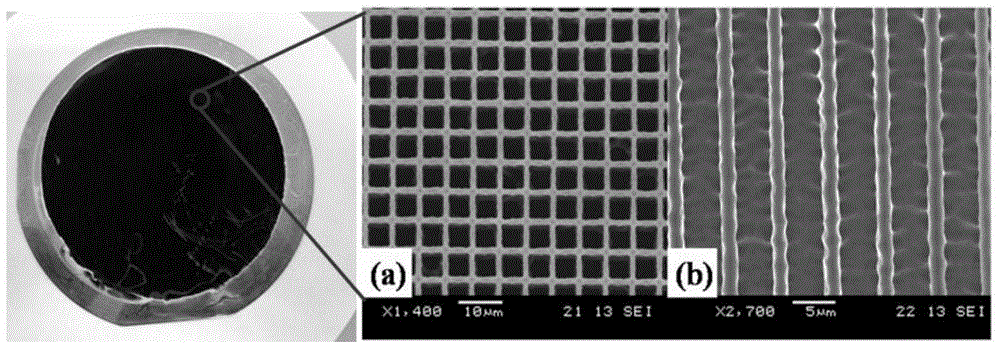

[0045] 1. Choose a silicon microchannel plate made of p-type silicon with (100) crystal orientation, the aperture size is 5×5×250, the unit is micron, the aspect ratio is 50, and the area is 1×1, and the unit is centimeter, such as figure 1 shown;

[0046] 2. Take 50ml of corrosion solution as HF:C2H5OH:H2O=100:125:10 volume ratio, soak the silicon microchannel plate for 3 minutes, and remove the silicon dioxide naturally grown on the surface of the silicon microchannel;

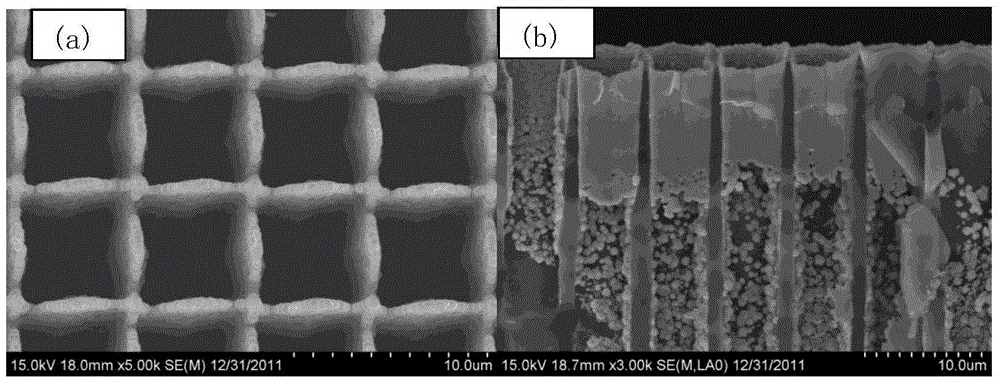

[0047] 3. Soak the silica-removed silicon microchannel plate in a surfactant whose concentration is Triton-X100:H2O=1 / 500 volume ratio, and soak for 60 seconds. Improve the wettability of the silicon microchannel hole wall and surface, drive out the air in the silicon microchannel hole; configure the electroless nickel plating solution, the ratio of which is NiCl 2 :NH 4 Cl:NaH 2 PO 4 =5:5.1:1.2 (mass ratio), configure 100ml ...

Embodiment 2

[0051] 1. A method for growing graphene in a microchannel plate is as follows: select the silicon microchannel plate prepared by (100) crystalline p-type silicon, the aperture size is 5 × 5 × 250, the unit is micron, and the aspect ratio is 50, Area 1cm×1cm, such as figure 1 shown;

[0052] 2. Take 50ml corrosion solution as HF:C 2 h 5 OH:H2O=100:125:10 volume ratio, soak the silicon microchannel plate for 4 minutes to remove the silicon dioxide naturally grown on the surface of the silicon microchannel;

[0053] 3. Soak the silica-removed silicon microchannel plate in surfactant with a concentration of Triton-X100:H 2 O=1 / 1000 volume ratio, soak for 30 seconds. Improve the wettability of the wall and surface of the silicon microchannel, and drive out the air in the hole of the silicon microchannel;

[0054] 4. Configure the electroless nickel plating solution, the ratio of which is NiCl 2 :NH 4 Cl:NaH 2 PO 4 =5:5.1:1.2 (mass ratio), configure 100ml solution, adjust t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com