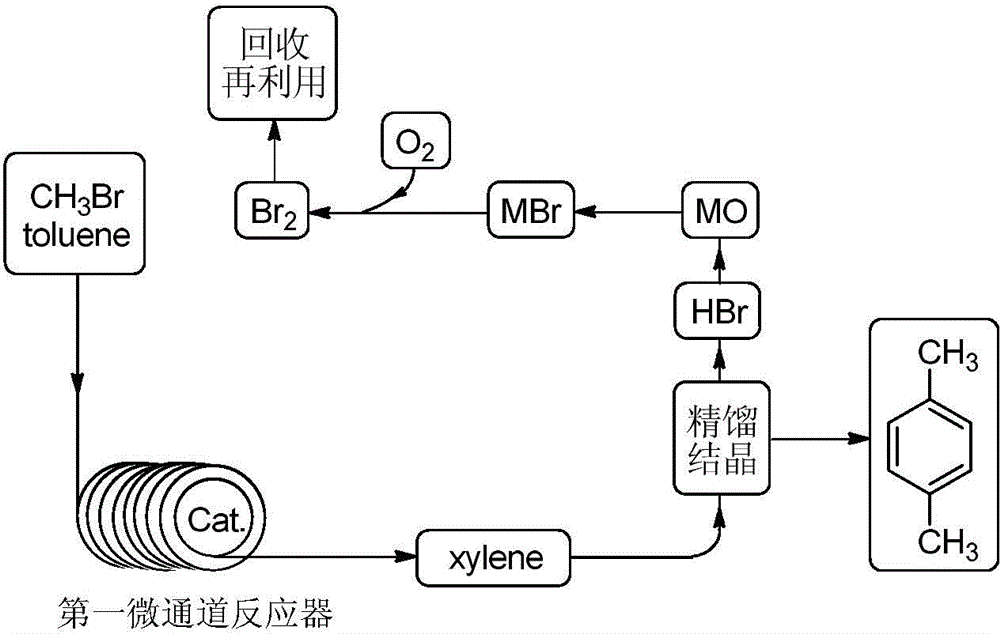

Method for continuously preparing paraxylene in microchannel reactor

A micro-channel reactor, para-xylene technology, applied in chemical instruments and methods, condensation between hydrocarbons and non-hydrocarbons to produce hydrocarbons, molecular sieve catalysts, etc., can solve the problems of high design requirements, complex processes, large energy consumption, etc. Achieve the effects of low cost, low reaction temperature and high conversion rate of reactants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

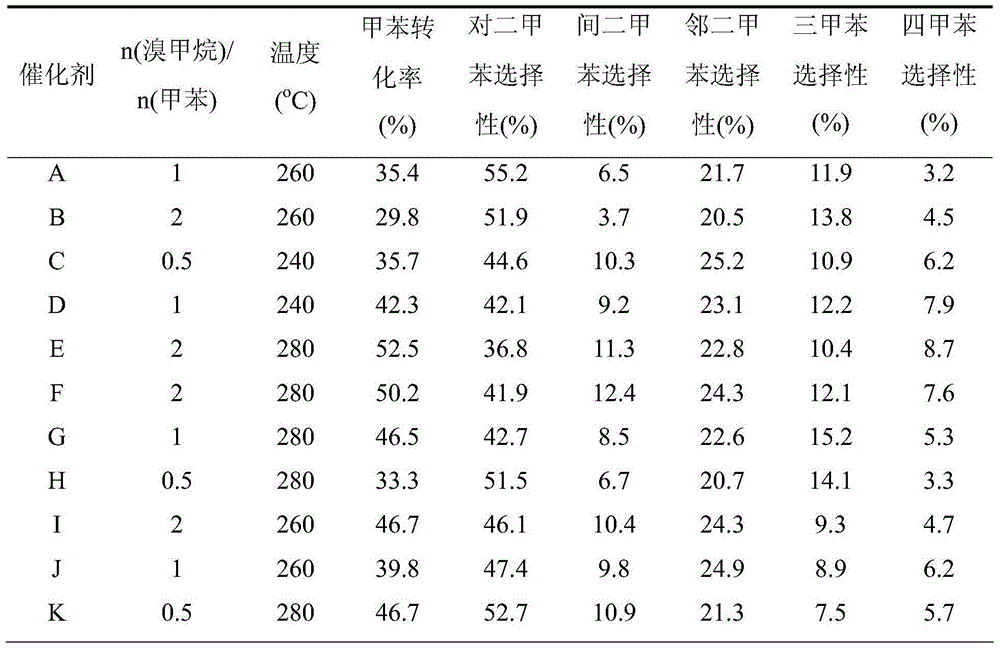

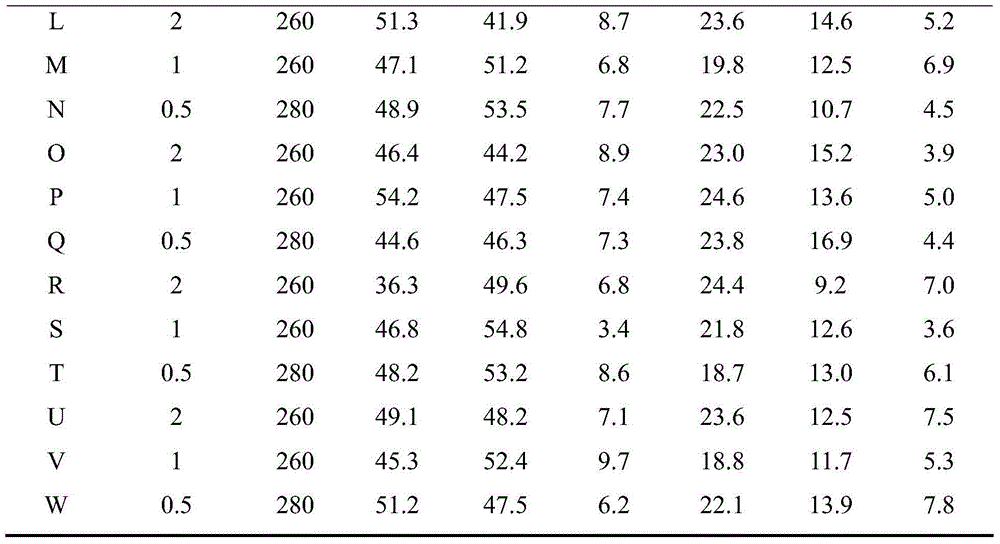

Examples

Embodiment 1

[0036] Weigh 0.6g of copper nitrate and dissolve it in 20g of deionized water, stir at room temperature for 10min to mix evenly, add 8g of HZSM-5 molecular sieve with a silicon-aluminum ratio of 60 purchased from Nankai University Catalyst Factory, and impregnate at room temperature for 8h. The impregnated mixture was evaporated to dryness in an oil bath at 90°C, and the obtained solid was first dried in an oven at 120°C overnight, then calcined in a muffle furnace at 550°C for 6 hours, and cooled naturally to obtain the modified catalyst A.

Embodiment 2

[0038] Weigh 0.6g of copper nitrate and dissolve it in 20g of deionized water, stir at room temperature for 10min to mix evenly, add 8g of HZSM-5 molecular sieve with a silicon-aluminum ratio of 80 purchased from Nankai University Catalyst Factory, and impregnate at room temperature for 8h. The impregnated mixed solution was evaporated to dryness in an oil bath at 90°C, and the obtained solid was first dried in an oven at 120°C overnight, then roasted in a muffle furnace at 550°C for 6 hours, and cooled naturally to obtain the modified catalyst B.

Embodiment 3

[0040] Weigh 0.6g of copper nitrate and dissolve it in 20g of deionized water, stir at room temperature for 10min to mix evenly, add 8g of HZSM-5 molecular sieve with a silicon-aluminum ratio of 100 purchased from Nankai University Catalyst Factory, and impregnate at room temperature for 8h. The impregnated mixture was evaporated to dryness in an oil bath at 90°C, and the obtained solid was first dried in an oven at 120°C overnight, then calcined in a muffle furnace at 550°C for 6 hours, and cooled naturally to obtain modified catalyst C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com