Method for synthesizing 1,5-diaminonaphthalene with 1-naphthylamine

A technology of diaminonaphthalene and naphthylamine, which is applied in the field of organic synthesis, can solve problems such as environmental pollution and complicated process, and achieve the effects of simple process, short reaction process and reduced production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 0.05g of sodium metavanadate and 1.5g of hydroxylamine sulfate respectively, put them into a three-necked flask connected with a thermometer and a condenser tube, then measure 15mL of glacial acetic acid and 5mL of deionized water into the three-necked flask, and then place the three-necked flask In a constant temperature water bath, stir at a constant temperature of 30°C for 20 minutes, then add 0.5g of 1-naphthylamine, raise the temperature to 80°C, and stop the reaction after 2 hours of constant temperature reaction. The final product was obtained after post-processing the reaction liquid, and the mass of 1,5-diaminonaphthalene in the product was quantitatively analyzed by liquid chromatography external standard method, and the yield was 3.53%.

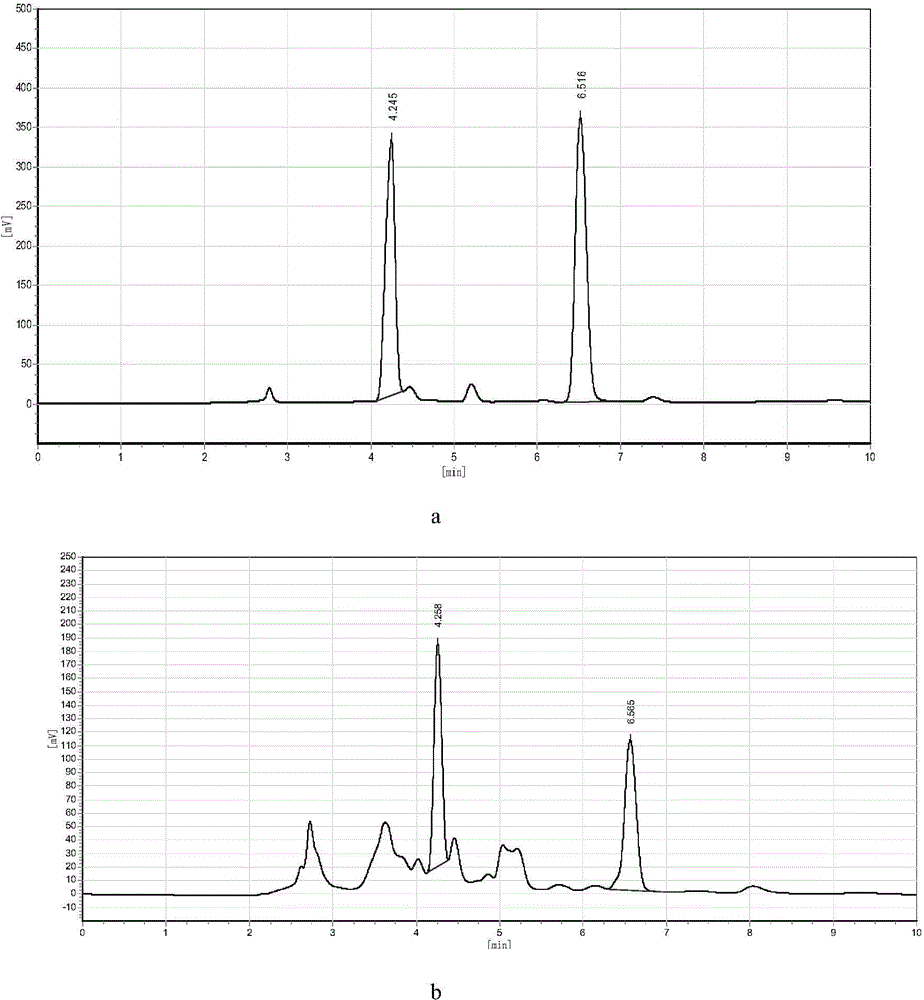

[0029] Analysis from liquid chromatography figure 1 It can be seen from (b) that 1,2-diaminonaphthalene is produced by the reaction, wherein the retention time of 1-naphthylamine is about 6.4 minutes, and the retention...

Embodiment 2

[0031] Weigh 0.05g of sodium metavanadate and 1.3g of hydroxylamine hydrochloride respectively, put them into a three-necked flask connected with a thermometer and a condenser, then measure 15mL of glacial acetic acid and 5mL of deionized water into the three-necked flask, and then place the three-necked flask In a constant temperature water bath, stir at 30°C for 20 minutes, then add 0.5g of 1-naphthylamine, raise the temperature to 80°C, and stop the reaction after 4 hours of constant temperature reaction. The final product was obtained after post-treatment of the reaction liquid, and the mass of 1,5-diaminonaphthalene in the product was quantitatively analyzed by liquid chromatography external standard method, which was 39.5 mg, and the yield was 7.15%.

Embodiment 3

[0033] Weigh 0.05g of sodium metavanadate and 1.3g of hydroxylamine hydrochloride respectively, put them into a three-necked flask connected with a thermometer and a condenser, then measure 15mL of glacial acetic acid and 5mL of deionized water into the three-necked flask, and then place the three-necked flask In a constant temperature water bath, stir at 30°C for 20 minutes, then add 0.5g of 1-naphthylamine, raise the temperature to 50°C, and stop the reaction after 4 hours of constant temperature reaction. The final product was obtained after post-treatment of the reaction liquid, and the mass of 1,5-diaminonaphthalene in the product was quantitatively analyzed by liquid chromatography external standard method, which was 6.35 mg, and the yield was 1.15%.

[0034] It can be seen from Example 3 that the conversion rate of 1-naphthylamine is relatively low when the reaction temperature is 50°C. It shows that an appropriate temperature range can effectively increase the yield of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com