Method for extracting high-purity theanine from fresh tea leaves

A technology of fresh tea leaves and theanine, applied in chemical instruments and methods, preparation of carboxylic acid amides, preparation of organic compounds, etc., can solve the problems of low product purity, achieve high separation efficiency, low production cost, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

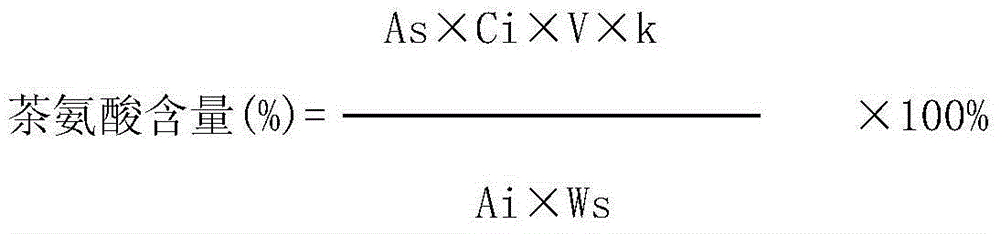

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: a kind of method extracting high-purity theanine from fresh tealeaves, it comprises the following steps:

[0024] S1. Constant temperature leaching: put fresh tea leaves in an extractor, add purified water with a temperature >80°C and soak for 2.0 hours at a constant temperature, the weight ratio of fresh tea leaves to purified water is 1:5, and the mixed solution in the extractor Cross 18 mesh sieves to obtain the filtrate;

[0025] S2. Centrifugation: Centrifuge the filtrate for 50 seconds at a temperature of 30°C, a pressure of 0.1 MPa, and a speed of 6500 rpm, and collect the centrifugate;

[0026] S3. Primary membrane concentration: use a reverse osmosis membrane with a rejection rate > 95% to concentrate the centrifugate at a concentration temperature of 30°C until the solid content is ≥ 5%;

[0027] S4. Solvent extraction: the primary membrane concentrate is extracted with ethyl acetate, the volume ratio of the concentrate to ethyl acetate is 1.2:1...

Embodiment 2

[0035] Embodiment 2: a kind of method extracting high-purity theanine from fresh tealeaves, it comprises the following steps:

[0036] S1. Constant temperature leaching: put fresh tea leaves in an extractor, add purified water with a temperature > 80°C and soak for 2.5 hours at a constant temperature, the weight ratio of fresh tea leaves to purified water is 1:8, and the mixed solution in the extractor Cross 24 mesh sieves to obtain the filtrate;

[0037] S2. Centrifugation: Centrifuge the filtrate for 70 seconds at a temperature of 50°C, a pressure of 0.3 MPa, and a rotation speed of 7000 rpm, and collect the centrifugate;

[0038] S3. Primary membrane concentration: use a reverse osmosis membrane with a rejection rate > 95% to concentrate the centrifugate at a concentration temperature of 50°C until the solid content is ≥ 5%;

[0039] S4. Solvent extraction: the primary membrane concentrate is extracted with ethyl acetate, the volume ratio of the concentrate to ethyl acetat...

Embodiment 3

[0047] Embodiment 3: a kind of method extracting high-purity theanine from fresh tealeaves, it comprises the following steps:

[0048] S1. Constant temperature leaching: put fresh tea leaves in an extractor, add purified water with a temperature >80°C and soak for 2.2 hours at a constant temperature, the weight ratio of fresh tea leaves to purified water is 1:6, and the mixed solution in the extractor Pass through a 20-mesh sieve to obtain the filtrate;

[0049] S2. Centrifugation: Centrifuge the filtrate for 60 seconds at a temperature of 35°C, a pressure of 0.2 MPa, and a rotation speed of 6800 rpm, and collect the centrifugate;

[0050] S3. Primary membrane concentration: use a reverse osmosis membrane with a rejection rate > 95% to concentrate the centrifugate at a concentration temperature of 40°C until the solid content is ≥ 5%;

[0051]S4. Solvent extraction: the primary membrane concentrate is extracted with ethyl acetate, the volume ratio of the concentrate to ethyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com