A kind of yttrium iron garnet single crystal film and preparation method thereof

A technology of yttrium iron garnet and single crystal thin film, which is applied in the field of liquid phase epitaxy preparation of yttrium iron garnet single crystal thin film, can solve the problems of large thin film, broken substrate, difficulty, etc., achieve roughness improvement, reduce Effect of small stress, increasing proportion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

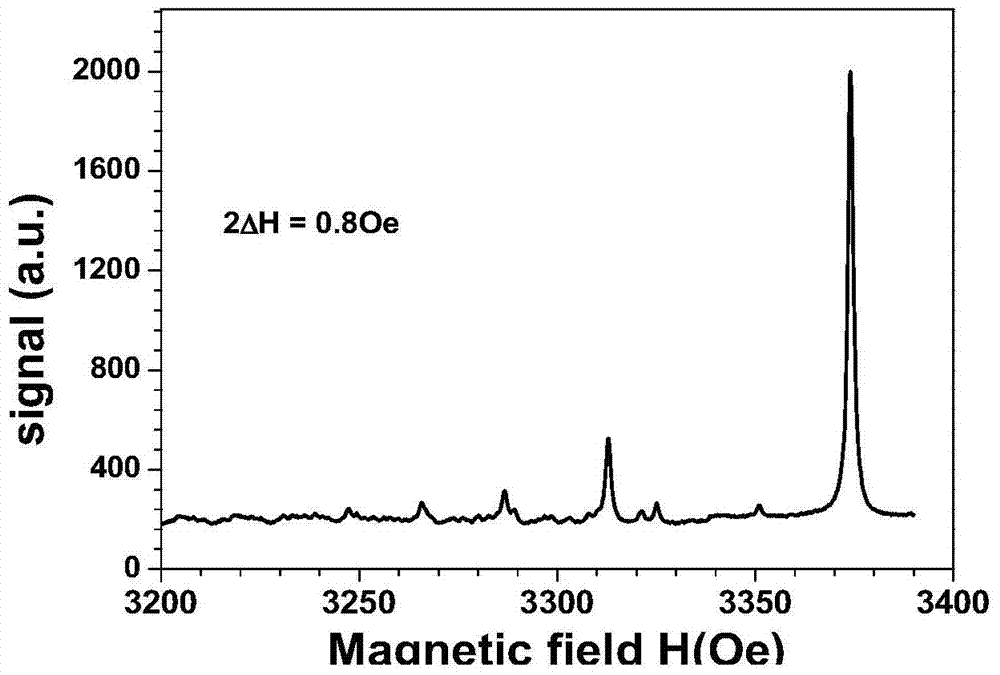

Image

Examples

preparation example Construction

[0016] A preparation method of yttrium iron garnet single crystal film, comprising the following steps:

[0017] Step 1: Melt Preparation: Take Y 2 o 3 , Fe 2 o 3 , La 2 o 3 , PbO, B 2 o 3 As the raw material, accurately weigh the above raw materials, where, Y 2 o 3 The mass percentage content is 0.44%, Fe 2 o 3 The mass percentage content is 10.31%, La 2 o 3 The mass percentage of PbO is 0.06%, the mass percentage of PbO is 87.44%, B 2 o 3 The mass percentage content is 1.75%; the above raw materials are mixed evenly, added to the crucible several times, melted at 1080-1140°C for 24 hours, then stirred with a platinum stirring rod for 8-12 hours, and mixed evenly to obtain liquid phase epitaxy growth the melt;

[0018] Step 2: Using gadolinium gallium garnet (GGG) as the substrate, the cleaning process of the substrate is as follows: soak the gadolinium gallium garnet substrate in trichlorethylene at 70-80°C for 3-10min, and then wash it at 70-80°C Soak in dei...

Embodiment

[0021] A preparation method of yttrium iron garnet single crystal film, comprising the following steps:

[0022] Step 1: According to the following molar ratio R1=Fe 2 o 3 / (La 2 o 3 +Y 2 o 3 )=27.1, R3=PbO / B 2 o 3=15.6, R4=(Y 2 o 3 +Fe 2 o 3 +La 2 o 3 ) / (Y 2 o 3 +Fe 2 o 3 +La 2 o 3 +PbO+B 2 o 3 )=0.138, calculate and weigh 39.7325g Y 2 o 3 , 928.1934g Fe 2 o 3 , 5.7330g La 2 o 3 , 7869.0079g PbO and 157.3332g B 2 o 3 As a raw material, the above-mentioned raw materials were mixed for two hours in a horizontal ball mill at a rate of 30 rpm, so that the raw materials were evenly mixed;

[0023] Step 2: Due to the large volume of the raw material powder, the platinum crucible cannot hold all the powder at one time. The raw material is added to the platinum crucible several times by adding the powder to melt and then re-feeding, and then put it in the vertical pulling furnace Melt at 1100°C for 24 hours; use a platinum stirring rod to stir at a speed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com