Preparation method of bi-generation lizntimn spun ferrite substrate material

A technology of gyromagnetic ferrite and substrate, applied in the direction of magnetism of inorganic materials, can solve the problems of composition segregation, complex synthesis process of low-melting glass, affecting the uniformity of crystal structure and gyromagnetic performance of ferrite materials, and achieve narrow ferromagnetic Effects of resonance linewidth, high squareness ratio, high saturation magnetic induction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

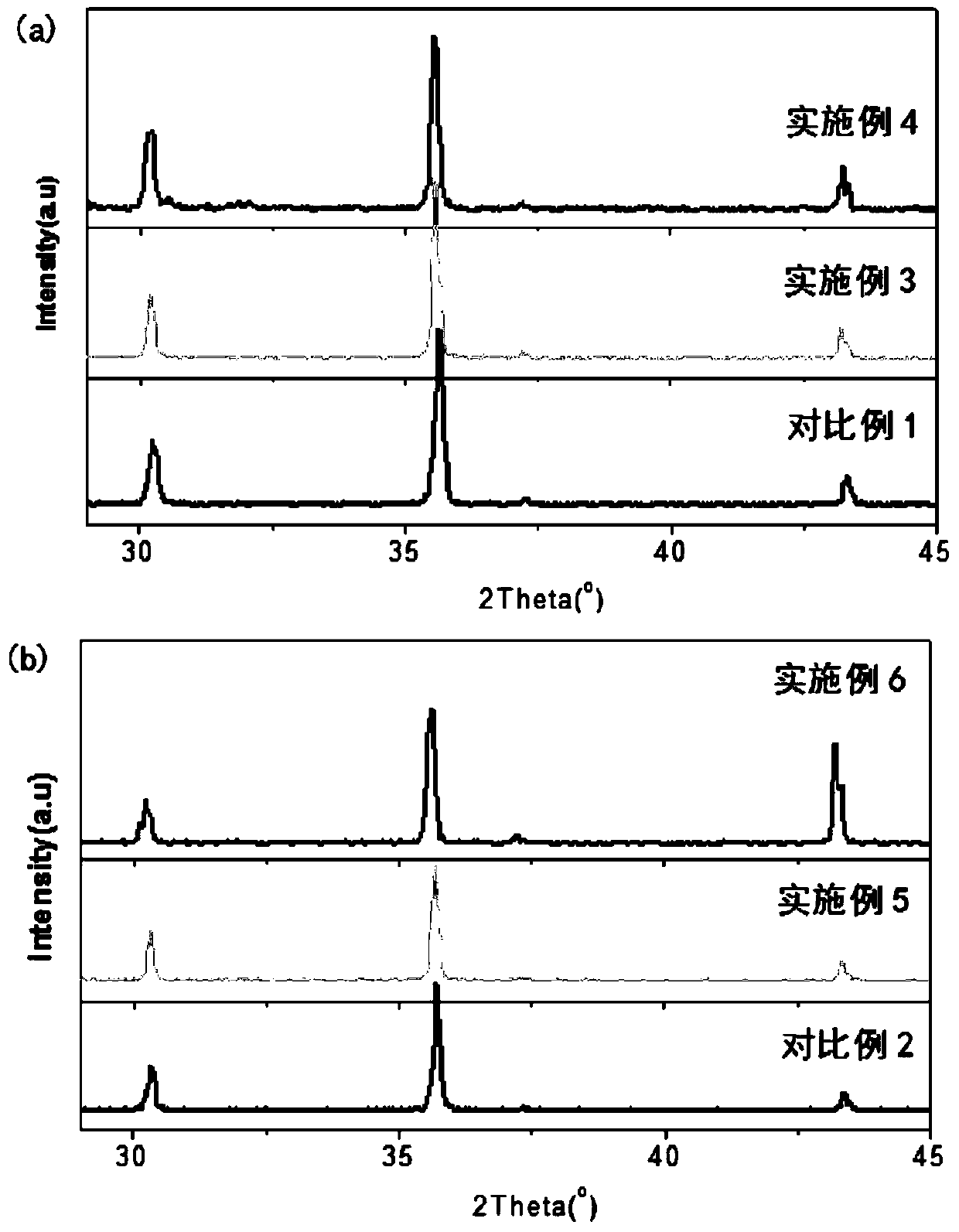

[0020] A preparation method of Bi-generation LiZnTiMn gyromagnetic ferrite substrate material, comprising the following steps:

[0021] Step 1: With Li 2 CO 3 , ZnO, TiO 2 , Mn 3 o 4 , Fe 2 o 3 and Bi 2 o 3 as raw material, according to Li 0.42 Zn 0.27 Ti 0.11 mn 0.1 Fe 2.1-x Bi x o 4 (x=0.002) The ratio of molecular formula is weighed, and preparation obtains initial powder;

[0022] Step 2: Perform wet ball milling for 4 hours according to the weight ratio of initial powder: deionized water: steel ball = 1:1.5:2.5, take out the obtained slurry and dry it at 90°C, put the dried powder Put it into a sintering furnace with an oxygen atmosphere, raise the temperature from room temperature to 840 °C at a rate of 2 °C / min and keep it for 2 hours, then cool down to room temperature naturally with the furnace to obtain a pre-sintered powder;

[0023] Step 3: Perform secondary ball milling on the calcined powder obtained in step 2, wherein the weight ratio of powder: ...

Embodiment 2

[0026] A preparation method of Bi-generation LiZnTiMn gyromagnetic ferrite substrate material, comprising the following steps:

[0027] Step 1: With Li 2 CO 3 , ZnO, TiO 2 , Mn 3 o 4 , Fe 2 o 3 and Bi 2 o 3 as raw material, according to Li 0.42 Zn 0.27 Ti 0.11 mn 0.1 Fe 2.1-x Bi x o 4 (x=0.003) The ratio of molecular formula is weighed, and preparation obtains initial powder;

[0028]Step 2: According to the weight ratio of initial powder: deionized water: steel ball = 1:1.5:2.5, carry out wet ball milling for 4 hours, take out the obtained slurry and dry it at 100°C, and put the dried powder Put it into a sintering furnace with an oxygen atmosphere, raise the temperature from room temperature to 860 °C at a rate of 2 °C / min and keep it warm for 2 hours, then cool down to room temperature naturally with the furnace to obtain a pre-sintered powder;

[0029] Step 3: Perform secondary ball milling on the calcined powder obtained in step 2, wherein the weight ratio...

Embodiment 3

[0032] A preparation method of Bi-generation LiZnTiMn gyromagnetic ferrite substrate material, comprising the following steps:

[0033] Step 1: With Li 2 CO 3 , ZnO, TiO 2 , Mn 3 o 4 , Fe 2 o 3 and Bi 2 o 3 as raw material, according to Li 0.42 Zn 0.27 Ti 0.11 mn 0.1 Fe 2.1-x Bi x o 4 (x=0.003) The ratio of molecular formula is weighed, and preparation obtains initial powder;

[0034] Step 2: According to the weight ratio of initial powder: deionized water: steel ball = 1:1.5:2.5, carry out wet ball milling for 4 hours, take out the obtained slurry and dry it at 100°C, and put the dried powder Put it into a sintering furnace with an oxygen atmosphere, raise the temperature from room temperature to 860 °C at a rate of 2 °C / min and keep it warm for 2 hours, then cool down to room temperature naturally with the furnace to obtain a pre-sintered powder;

[0035] Step 3: Perform secondary ball milling on the calcined powder obtained in step 2, wherein the weight rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com