Anode corrosion foil manufacturing method and aluminum foil corrosion electrolytic cell

A manufacturing method and anode corrosion technology, applied in electrolytic capacitors, circuits, capacitors, etc., can solve problems such as low electrostatic capacity, poor bending strength, and affect the surface area of corrosion holes, so as to ensure mechanical strength and improve consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

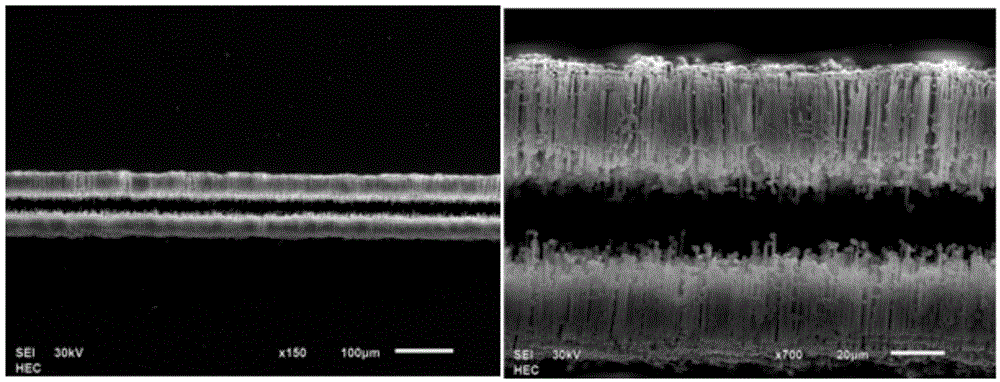

Embodiment 1

[0024] Pretreatment: Use domestic aluminum foil with a thickness of 120 μm, first put the aluminum foil into a sodium hydroxide solution with a concentration of 1-4Wt%, and treat it at 45°C for 1min; after washing with water, put it into a mixture of 30% sulfuric acid and 5Wt% hydrochloric acid, at 60°C, Process 1min;

[0025] 1. Electrolysis: In the first half of V, direct current is applied between the plates in the 30Wt% sulfuric acid + 6Wt% hydrochloric acid + 1.5Wt% aluminum ion bath, and the current density is 0.5A / cm 2 , the temperature is preferably 72-78°C. In this embodiment, it is 73.5°C. The pretreated aluminum foil is treated for 75-95s, which is 90s in this embodiment; Chemical corrosion in the solution at 35°C for 75-95s, 90s in this example; then wash with water;

[0026] Two electrolysis: put the corroded foil after the electrolytic treatment into the aqueous solution whose concentration is 10Wt% nitric acid+(0.01-0.1)Wt% polyacrylic acid, the concentration o...

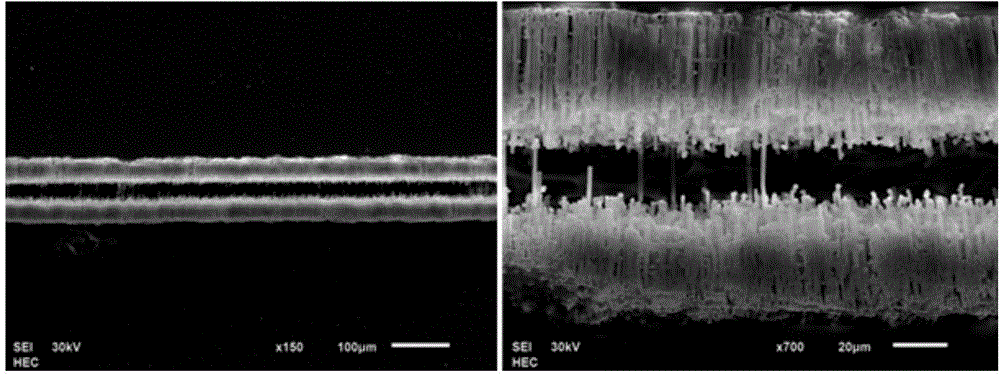

Embodiment 2

[0031] Pretreatment: Use domestic aluminum foil with a thickness of 120 μm, first put the aluminum foil into a sodium hydroxide solution with a concentration of 1-4Wt%, and treat it at 45°C for 1min; after washing with water, put it into a mixture of 30% sulfuric acid and 5Wt% hydrochloric acid, at 60°C, Process 1min;

[0032] 1. Electrolysis: The first half of electrolysis applies direct current to the plate in the 45Wt% sulfuric acid + 2Wt% hydrochloric acid + 1.5Wt% aluminum ion bath, and the current density is 0.5A / cm 2 , the temperature is 72.5°C, and the pretreated aluminum foil is treated for 87s; after electrolysis, half V is chemically etched at 25-75°C in the aluminum ion solution of 45Wt% sulfuric acid + 2Wt% hydrochloric acid + 1.5Wt%, and this embodiment is 45 Chemical corrosion at ℃ for 87s, then washed with water;

[0033] 2. Electrolysis: Put the corroded foil after electrolytic treatment into an aqueous solution with a concentration of 4Wt% nitric acid + 0.1W...

Embodiment 3

[0038]Pretreatment: Use domestic aluminum foil with a thickness of 120 μm, first put the aluminum foil into a sodium hydroxide solution with a concentration of 1-4Wt%, and treat it at 45°C for 1min; after washing with water, put it into a mixture of 30% sulfuric acid and 5Wt% hydrochloric acid, at 60°C, Process 1min;

[0039] 1. Electrolysis: the first half of electrolysis applies direct current to the plate in the 30Wt% sulfuric acid + 5Wt% hydrochloric acid + 0.5Wt% aluminum ion bath, and the current density is 0.5A / cm 2 , the temperature is 74.5°C, and the pretreated aluminum foil is treated for 84s; after electrolysis, half V is chemically corroded at 55°C for 84s in 30Wt% sulfuric acid + 5Wt% hydrochloric acid + 0.5Wt% aluminum ion solution, and then washed with water;

[0040] 2. Electrolysis: Put the corroded foil after electrolytic treatment into an aqueous solution with a concentration of 10Wt% nitric acid + 0.1Wt% polyacrylic acid, and conduct DC electrolytic corrosi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile load | aaaaa | aaaaa |

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com