Preparation method for bismuth oxide nano-particle/titania nano-tube array

A nanotube array and nanoparticle technology, which is applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of poor controllability of particle size and dispersion, complex process conditions, etc., and achieve improvement Effects of light absorption ability, low cost, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

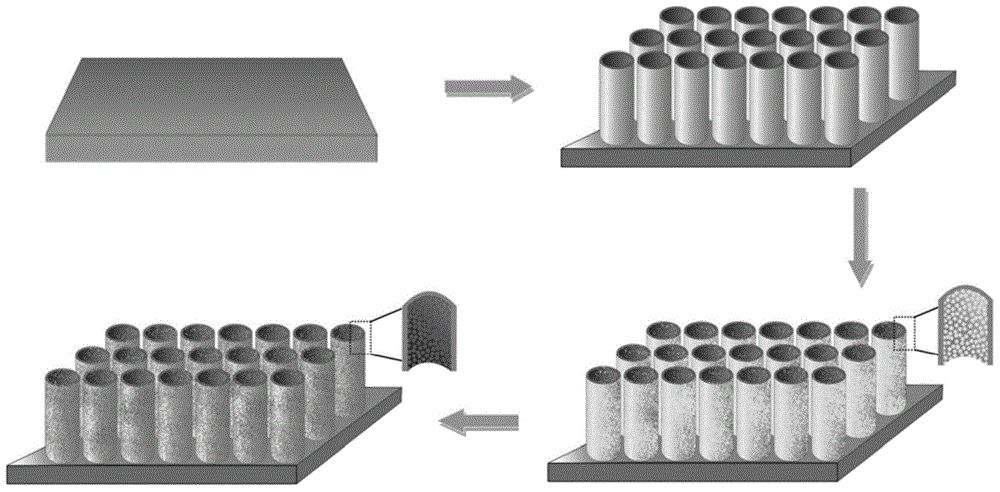

[0042] The preparation method of the bismuth oxide nanoparticle / titanium dioxide nanotube array of the present invention comprises:

[0043] S1. Pretreatment of titanium sheet.

[0044] Specifically, the titanium sheet is cleaned. Wherein, the titanium sheet is pure titanium or titanium alloy, and the size of the titanium sheet is 1.5cm×3.0cm. Use acetone, ethanol and deionized water in sequence to ultrasonically clean the titanium sheet for 20-60 minutes.

[0045] S2. Preparation of TiO by anodic oxidation 2 array of nanotubes.

[0046] Specifically, the cleaned titanium sheet is used as the anode, the platinum sheet is used as the cathode, and inserted into the ethylene glycol solution containing ammonium fluoride and water at the same time, and a voltage is applied for anodic oxidation to obtain TiO 2 nanotube arrays, and then the prepared TiO 2 Nanotube arrays are calcined.

[0047] Wherein, in the ethylene glycol solution, the mass percent concentration of ammonium ...

Embodiment 1

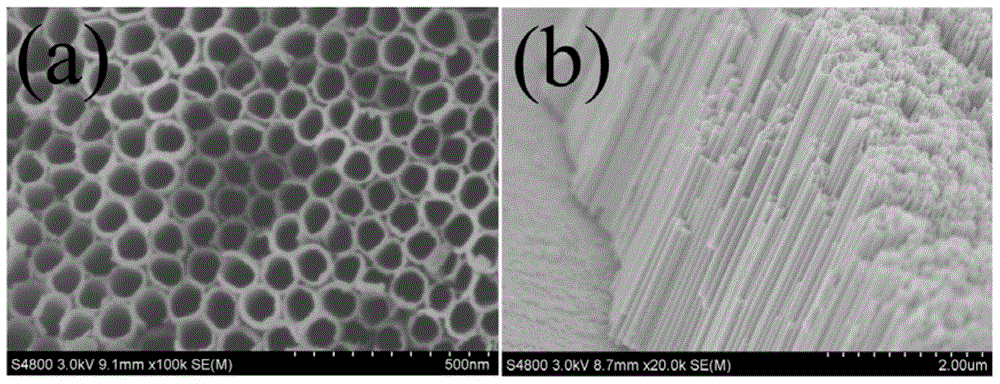

[0060] (1) Pretreatment of titanium sheets and preparation of TiO by anodic oxidation 2 array of nanotubes. Ultrasonic cleaning of the pure titanium substrate with acetone and absolute ethanol for 20 min. Using a platinum sheet electrode as the cathode, insert it into the electrolyte solution of ethylene glycol (98v%) and water (2v%) containing 0.5wt% ammonium fluoride at the same time, apply a voltage of 50V for 2h, and prepare TiO 2 The nanotube array was then calcined at 400°C for 2h to transform it from an amorphous state to anatase.

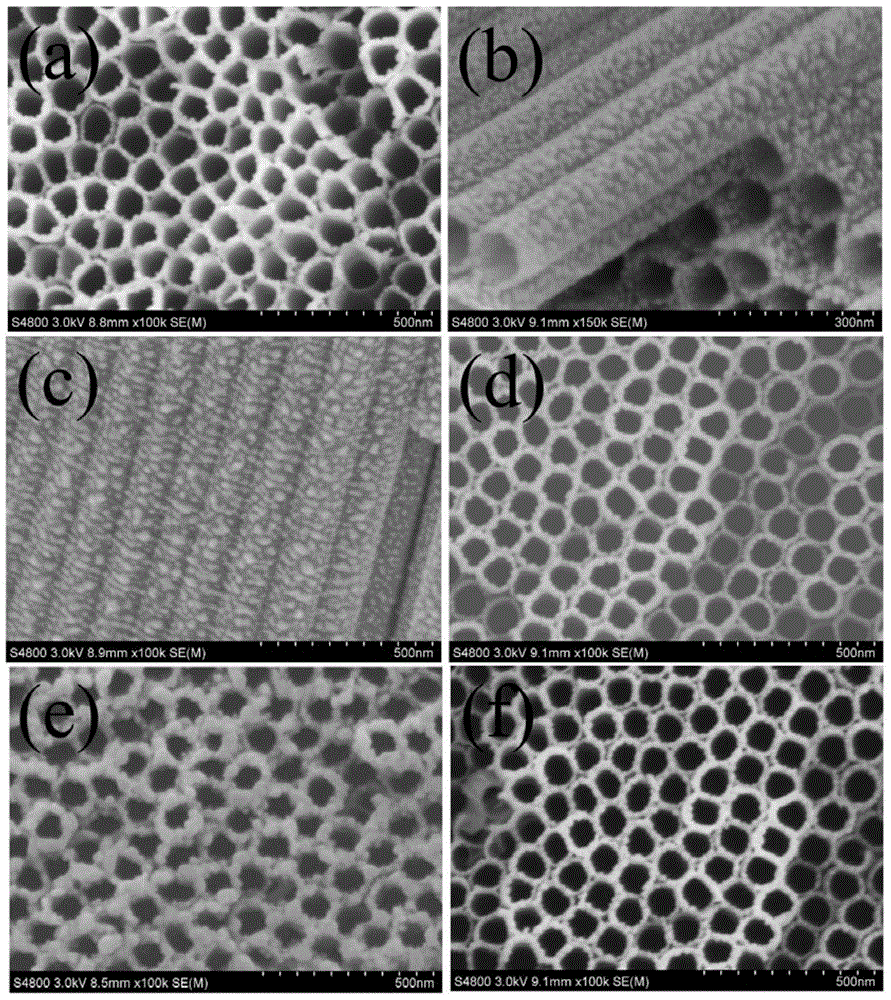

[0061] (2) A self-assembly method was used to prepare a titanium dioxide nanotube array composited with bismuth oxide nanoparticles. Prepare 5.0mM Bi(NO 3 ) 3 ·5H 2O ethylene glycol solution and 0.1M NaOH absolute ethanol solution, after the solution is uniformly dispersed, put the two solutions into the ultrasonic machine for ultrasonication, (then the titanium dioxide nanotube array) is immersed in ethylene glycol solution and absolut...

Embodiment 2

[0064] (1) Pretreatment of titanium sheets and preparation of TiO by anodic oxidation 2 The preparation of the nanotube array is the same as in Example 1.

[0065] (2) Preparation of bismuth oxide nanoparticles composite titania nanotube arrays by self-assembly: prepare 10.0mMBi(NO 3 ) 3 ·5H 2 The ethylene glycol solution of O and the absolute ethanol solution of 1.0M NaOH, after the solutions are evenly dispersed, put the two solutions into the ultrasonic machine for ultrasonication, first immerse in the ethylene glycol solution, then in the absolute ethanol solution, and then dip into the two solutions All for 20 minutes. After taking out the samples, wash the titanium sheets with absolute ethanol, dry them in an oven at 40°C, and chemically deposit once. Put the dried samples in a muffle furnace and calcinate at 450°C for 5 hours to obtain bismuth oxide nanoparticle composites. TiO 2 array of nanotubes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com