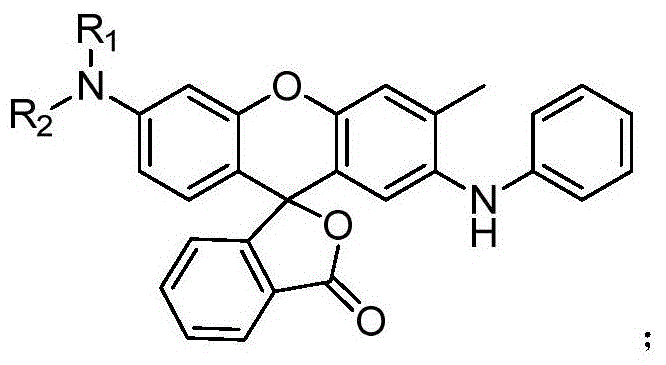

A kind of method of synthesizing fluoran class black thermal pressure-sensitive coupler

A technology of fluoranes and couplers, applied in the field of organic dyes, can solve problems such as waste acid generation, increased production risk, and environmental protection issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

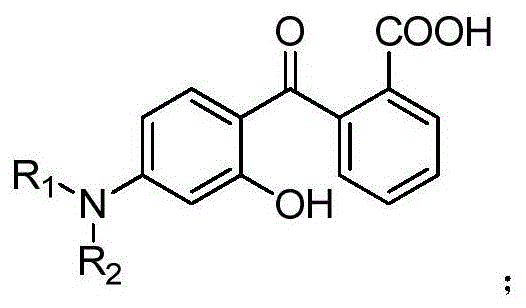

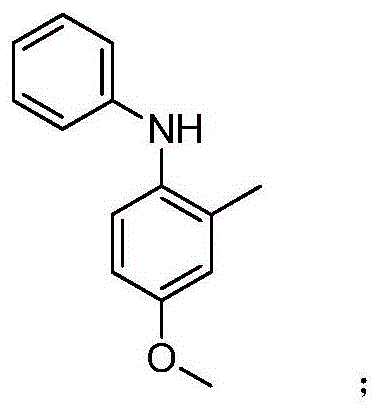

[0045] In a 500ml reactor, add 200ml of toluene, add 37.5g (0.1mol) of benzophenone acid, 21.3g (0.1mol) of DPA, catalyst NKC-950g(H + > 0.24mol), heat and stir at 110°C for 10 hours, then cool to 80°C, filter, wash NKC-9 with a small amount of toluene and apply it, add 120ml of water to the filtrate, and then add 30% sodium hydroxide dropwise to adjust the pH of the water phase> After 10, heat and reflux for 2 to 4 hours, divide the water phase, cool the organic phase to below 20°C, filter, wash the filter cake with a small amount of methanol, and dry to obtain 45.7 g of the product with a yield of 85%. Test, the content of the compound of formula I in the product> 99.5%, melting point 207.5~208℃.

[0046] The qualitative and quantitative analysis data of the product are as follows: 1H NMR (400MHz, CDCl3): δ6.4-7.8(m,18H),4.0(s,1H),3.1(t,J=7.3Hz,2H),2.34(s , 3H), 2.12 (s, 3H), 1.15 (t, J = 7.3 Hz, 2H); MS (ESI): m / z = 539 (M + +H).

[0047] R in the benzophenone acid described in ...

Embodiment 2

[0049] In a 500ml reactor, add 200ml of toluene, add 37.5g (0.1mol) of benzophenone acid, 21.3g (0.1mol) of DPA, perfluorosulfonic acid resin Nafion-H60g(H + > 0.12mol), heated and stirred at 110°C for 8 hours, then cooled to 80°C, filtered, Nafion-H was washed with a small amount of toluene and applied, the filtrate was added with 100ml of water, and then 30% sodium hydroxide was added dropwise to adjust the pH of the water phase> After 10, heat and reflux for 2 to 4 hours, divide the water phase, cool the organic phase to below 20°C, filter, wash the filter cake with a small amount of methanol, and dry to obtain 47.2 g of the product, with a yield of 90%. Test, the content of the compound of formula I in the product> 99.5%, melting point 208.1-208.6°C.

[0050] The qualitative and quantitative analysis data of the product are as follows: 1H NMR (400MHz, CDCl3): δ6.4-7.8(m,19H),4.0(s,1H),3.1(t,J=7.3Hz,2H), 2.12(s ,3H),1.15(t,J=7.3Hz,2H); MS(ESI): m / z=525(M + +H).

[0051] R in the...

Embodiment 3

[0053] In a 500ml reactor, add 200ml of xylene, add 37.5g (0.1mol) of benzophenone acid, 21.3g (0.1mol) of DPA, NKC-950g(H + > 0.12mol), heat and stir at 115°C for 9 hours, then cool to 80°C, filter, wash NKC-9 with a small amount of toluene and apply, add 120ml of water to the filtrate, and then add 30% sodium hydroxide dropwise to adjust the pH of the water phase> After 10, heat and reflux for 2 to 4 hours, divide the water phase, cool the organic phase to below 20°C, filter, wash the filter cake with a small amount of methanol, and dry to obtain 48.5 g of product, with a yield of 90%, tested by HPLC After that, the content of the compound of formula I in the product> 99.5%, melting point 207.5~208℃. R in the benzophenone acid described in this example 1 Represents ethyl, R 2 Represents p-methylphenyl.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com