Additive composition, thermal insulation coating and use

A composition and additive technology, applied in polyester coatings, epoxy resin coatings, reflective/signal coatings, etc., can solve problems such as improved thermal insulation performance and complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the additive composition of the present invention is a method commonly used in the art, for example, it can be obtained by mixing various components.

[0038] The additive composition of the present invention can be added to any synthetic resin emulsion base paint or solvent-based base paint, so that the paint has excellent thermal insulation performance. At the same time, the additive composition of the invention can be fully mixed with various base paints without changing other physical and chemical properties of the base paint.

[0039]

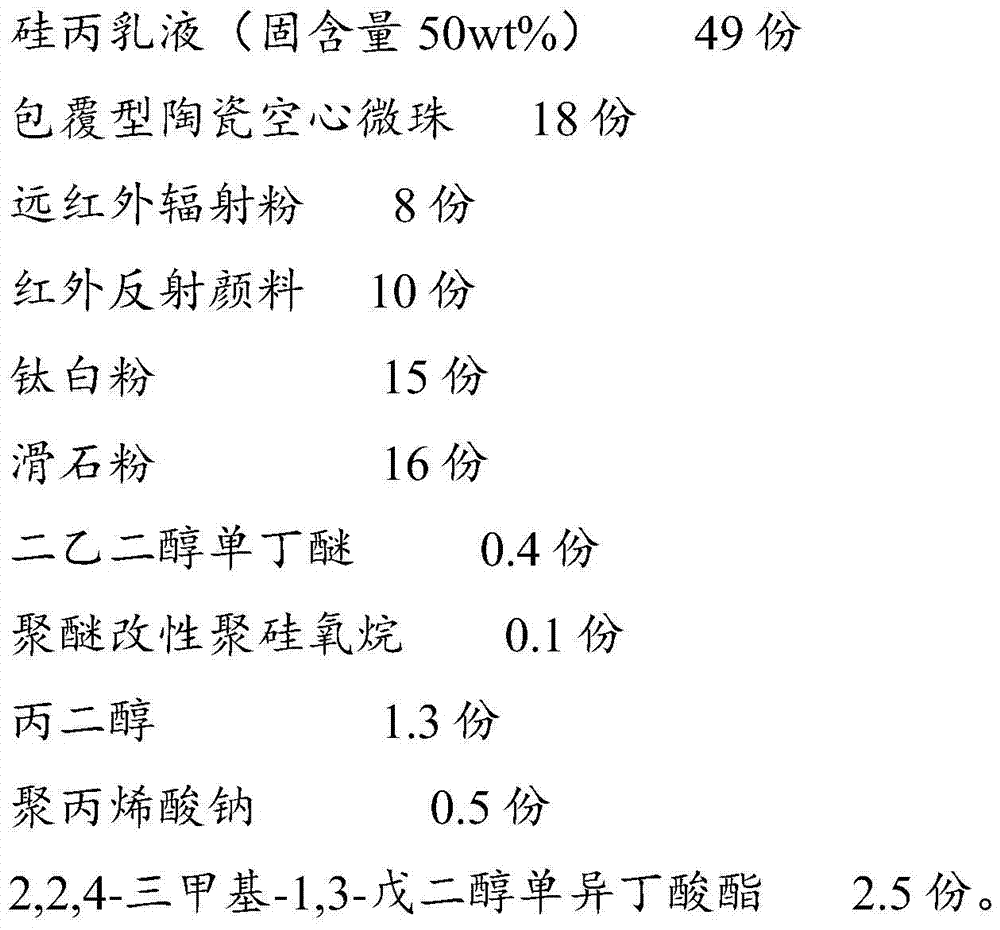

[0040] The heat-insulating paint of the present invention includes a base paint and the additive composition described above. The heat insulating coating of the present invention comprises the following components by weight: 20-30 parts of base resin; 8-24 parts of pigment; 5-35 parts of filler; 2-8 parts of coating additive; 5-20 parts of far-infrared radiation powder; and 5-15 parts of infrared reflect...

preparation example 1

[0077] The ceramic hollow microspheres mixed uniformly as shown in Table 1 are added to titanium sulfate aqueous solution (the aqueous solution formed by adding 58 parts of titanium sulfate to 500 parts of industrial tap water) and fully soaked, and then sodium hydroxide is added to adjust the pH to 10; Sodium chloride was stirred for 30 minutes; then the pH was adjusted to 4, followed by adding magnesium chloride and aluminum chloride, stirring at a stirring speed of 60 rpm for 60 minutes, and ultrasonic vibration while stirring; then neutralizing the pH to 7 with sodium hydroxide, Continue to stir for 60 minutes, filter, wash, and dry, then move into a high-temperature-resistant container, place it in a high-temperature resistance furnace for calcination, and calcine at a calcination temperature of 400°C for 4 hours, then raise the temperature to 600°C for 2 hours, and leave the furnace to cool naturally to obtain the package Covered ceramic hollow microspheres, the thickness...

Embodiment 1

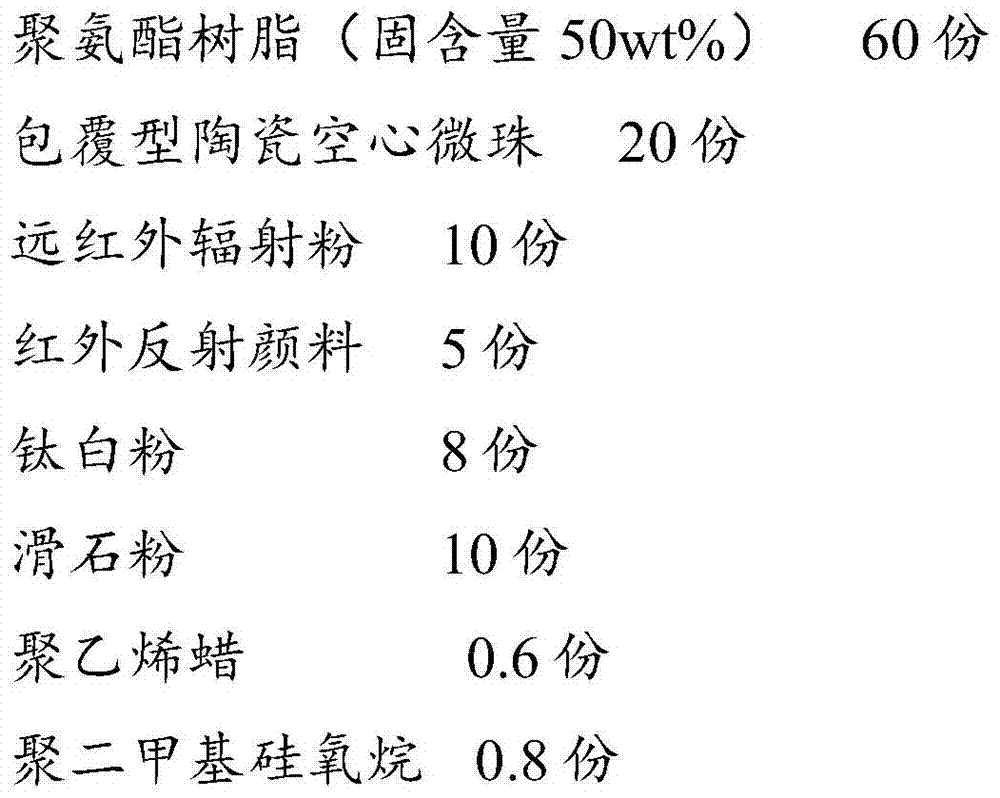

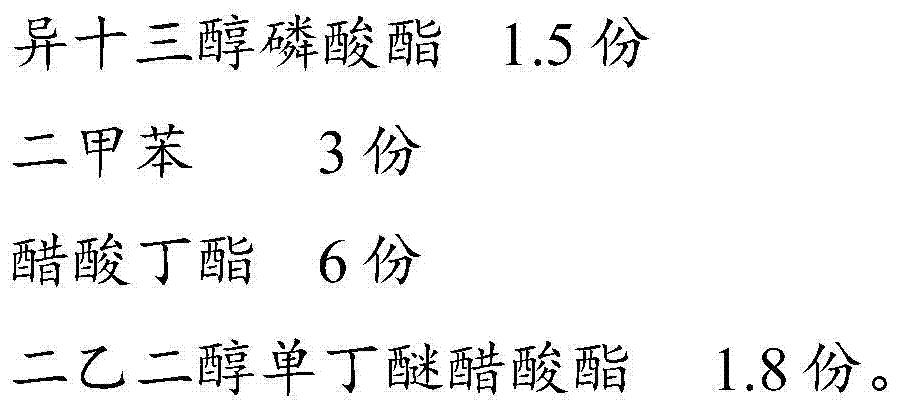

[0080] Example 1 - Solvent Based Insulation Coating

[0081]

[0082] Component A:

[0083]

[0084]

[0085] Component B:

[0086] Hexamethylene diisocyanate.

[0087] Group A: Group B = 13:1.

[0088] The above-mentioned components are stirred and dispersed, stirred and toned, product inspected, filtered, and packaged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com