Waterproof dye-based ink for ink-jet printing and preparation method thereof

A dye ink and inkjet printing technology, which is applied in the fields of inks, applications, household appliances, etc., can solve the problems of poor sample color performance, complicated preparation process, and high ink cost, and achieve strong printing color expression, simple preparation method, and low cost. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

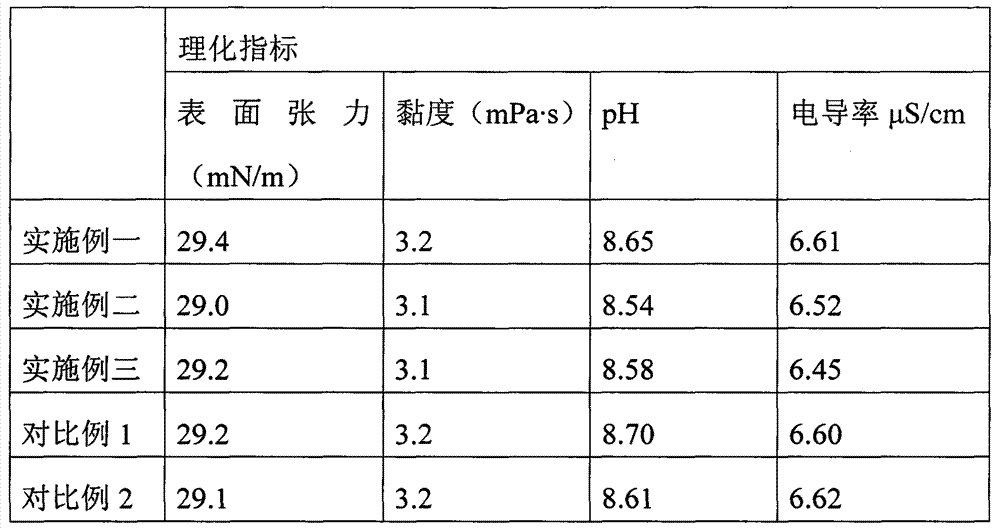

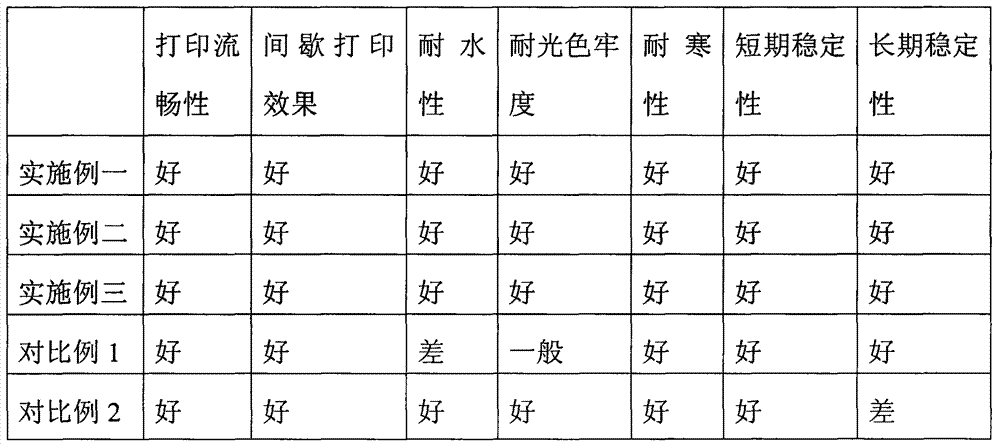

[0026] Embodiment one waterproof dye ink

[0027] The waterproof dye ink comprises the following components and parts by weight: 20 parts of azo mixed black direct dye, 0.6 part of modified polyurethane resin emulsion (solid content), 30 parts of acrylic resin emulsion (solid content), 5 parts of glycerin, poly 1 part of oxyethylene alkyl ether, 10 parts of diethylene glycol, 0.4 part of 5-chloro-2-methyl-4-isothiazolin-3-one, 1 part of sodium citrate, and 32 parts of deionized water. 1kg per serving.

[0028] Preparation method: add water into the reactor, slowly add glycerin, polyoxyethylene alkyl ether, diethylene glycol and 5-chloro-2-methyl-4-isothiazolin-3-one under stirring condition of 60r / min, To obtain the auxiliary agent mixture; under stirring conditions, slowly add acrylic resin emulsion and modified polyurethane resin emulsion to the auxiliary agent mixture, then slowly add azo mixed black direct dye, add sodium citrate, and stir evenly to obtain the mixed solut...

Embodiment 2

[0029] Embodiment two waterproof dye ink

[0030] Waterproof dye ink, including the following components and parts by weight: 5 parts of azo mixed black direct dye, 0.3 parts of modified polyurethane resin, 20 parts of acrylic resin, 3 parts of polyethylene glycol, 0.2 part of polyoxyethylene fatty acid ester , 5 parts of diethylene glycol, 0.3 parts of potassium sorbate, 0.2 parts of sodium hydroxide, and 66 parts of deionized water. 1kg per serving.

[0031] The preparation method is similar to Example 1.

Embodiment 3

[0032] Embodiment three waterproof dye ink

[0033] Waterproof dye ink, including the following components and parts by weight: 15 parts of azo mixed black direct dye, 0.5 part of modified polyurethane resin, 25 parts of acrylic resin, 4 parts of polyethylene glycol, and 0.4 part of polyoxyethylene fatty acid ester , 6 parts of diethylene glycol, 0.4 parts of potassium sorbate, 0.4 parts of sodium hydroxide, 0.5 parts of polyvinyl alcohol, and 47.8 parts of deionized water. 1kg per serving.

[0034] The preparation method is similar to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com