Method for improving fermentation productivity of carotenoid

A carotene and yield technology, applied in the field of high antioxidant carotenoids preparation, can solve the problems of long production cycle, poor functionality, difficult extraction and the like, and achieve the effects of low production cost, short fermentation cycle and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

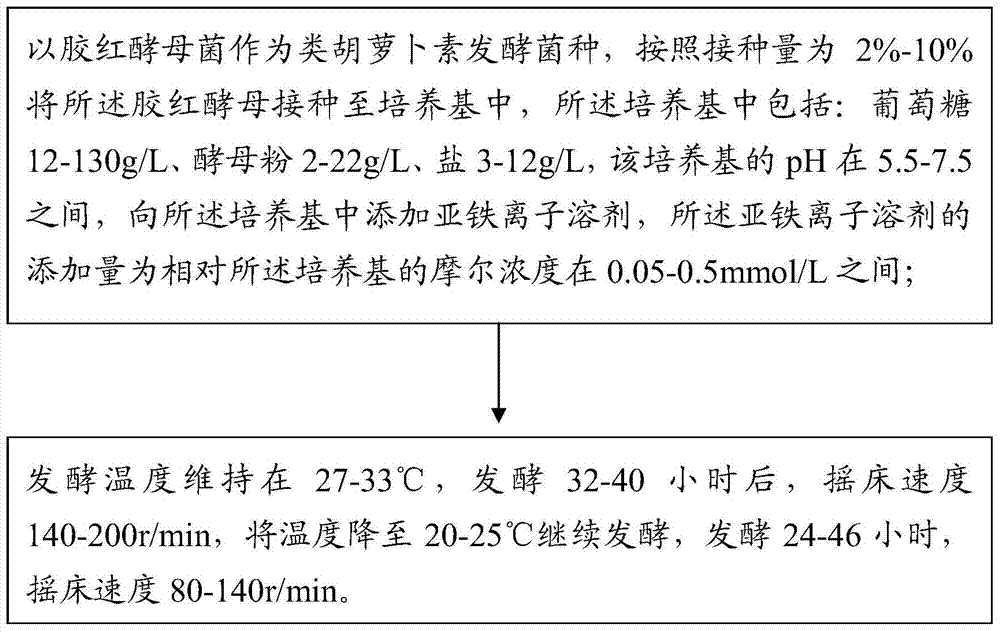

[0016] Using Rhodotorula gum as the carotenoid fermentation strain, inoculate the Rhodotorula gum into the culture medium according to the inoculum size of 5%. The culture medium includes: glucose 12g / L, yeast powder 2g / L, salt 3g / L, the pH of the medium is 5.5, add ferrous ion solvent to the medium, and maintain the fermentation temperature at 27°C. After 32 hours of fermentation, the shaker speed is 140r / min, and the temperature is lowered to 20°C to continue Fermentation, fermentation 24 hours, shaker speed 80r / min.

[0017] The preservation number of the Rhodotorula gum is CGMCC No.10123.

[0018] The ferrous ion solvent is ferrous sulfate, and the added amount of ferrous sulfate is 0.05mmol / L relative to the molar concentration of the medium.

Embodiment 2

[0020] Using Rhodotorula gum as the carotenoid fermentation strain, inoculate the Rhodotorula gum into the culture medium according to the inoculum size of 7%. The culture medium includes: glucose 130g / L, yeast powder 22g / L, salt 12g / L, the pH of the medium is 7.5, add ferrous ion solvent to the medium, the fermentation temperature is maintained at 29°C, after 40 hours of fermentation, the shaker speed is 200r / min, and the temperature is lowered to 25°C to continue Fermentation, fermentation 38 hours, shaker speed 140r / min.

[0021] The ferrous ion solvent is ferrous sulfate, and the added amount of ferrous sulfate is 0.5 mmol / L relative to the molar concentration of the medium.

Embodiment 3

[0023] Using Rhodotorula gum as the carotenoid fermentation strain, inoculate the Rhodotorula gum into the culture medium according to the inoculum size of 5%. The culture medium includes: glucose 71g / L, yeast powder 11g / L, salt 7.5g / L, the pH of the medium is 6.5, add ferrous ion solvent to the medium, the fermentation temperature is maintained at 30°C, after 36 hours of fermentation, the shaking table speed is 170r / min, and the temperature is lowered to 22°C Continue to ferment, ferment for 35 hours, shaker speed 110r / min.

[0024] The ferrous ion solvent is ferrous sulfate, and the added amount of ferrous sulfate is 0.275mmol / L relative to the molar concentration of the medium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com