Auxiliary pumping device for oil extraction

A technology for oil and flow pipes, which is applied in the fields of fluid extraction, earthwork drilling, cleaning equipment, etc., can solve the problems of high workover labor, slow production recovery, and high costs, saving operating time and costs, and increasing the contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

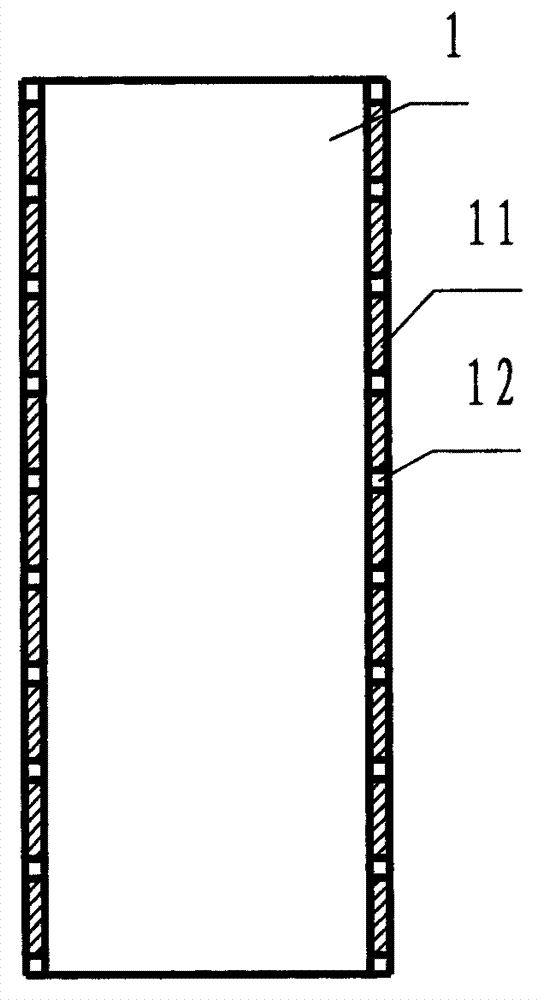

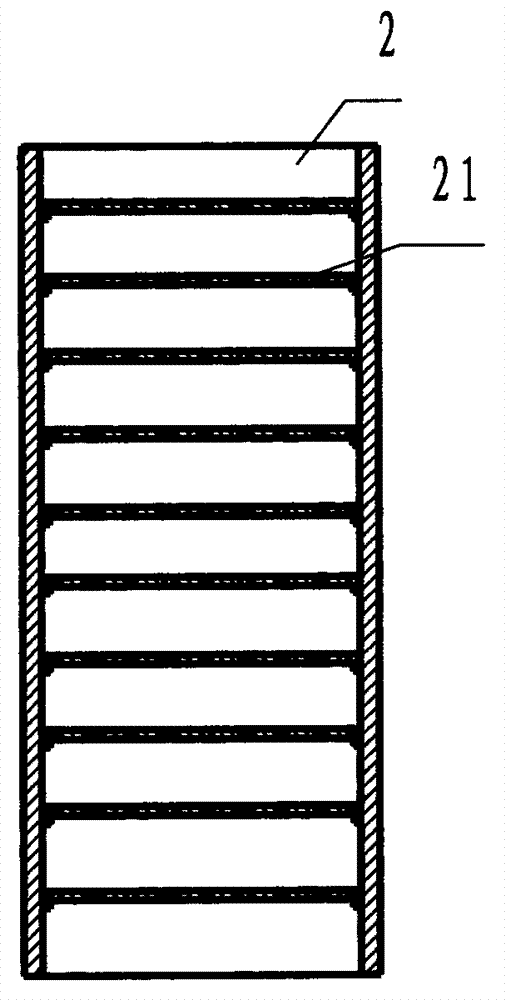

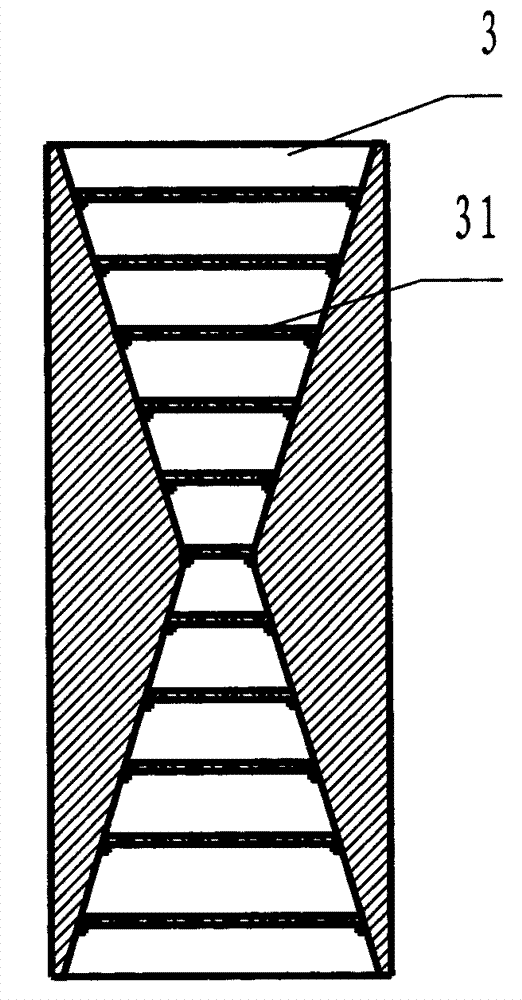

[0020] like figure 1 , figure 2 , image 3 As shown, the pumping aid device for oil exploitation of the present invention includes three sections of pipe body, the first section of pipe body is an oil inlet pipe 1, and this pipe 1 is at the lowermost end of the oil well, and extends into the oil layer to be exploited, and the oil inlet pipe 1 The pipe wall 11 is provided with several oil inlet holes 12, the second section of the pipe body is the oil passage pipe 2 in the middle, meshes 21 are respectively arranged on several cross-sections of the inner cavity of the pipe 2, and the third section of the pipe body is the outlet pipe. Oil pipe 3, the oil outlet of the oil outlet pipe 3 is connected with the oil well pump, and the oil outlet pipe 3 is a sub-bell type pipe body, which can reduce the wave flow of crude oil and improve the stability of the oil flow. The sub-bell type pipe body is like two The sub-bells formed by docking the small mouths of two trumpets together, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com