System for preparing 1-amino-8-naphthol-4,6-disulfonic acid

A technology of disulfonic acid and amino group, applied in the field of chemical industry, can solve the problems of destructive enhancement of natural resources, large industrial energy consumption, backward management level, etc., and achieves reduction of raw material cost and consumption, energy saving and emission reduction of process conditions, and optimization of production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

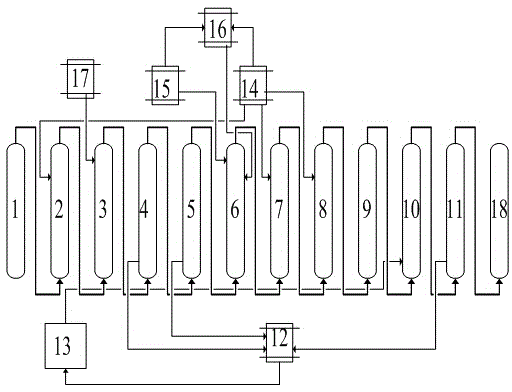

[0015] Such as figure 1 A system for preparing 1-amino-8-naphthol-4,6-disulfonic acid is shown, which includes a raw material storage tower 1, a first synthesis reaction tower 2, a second synthesis reaction tower 3, and a filtration reaction tower 4. The first centrifugal reaction tower 5, the third synthesis reaction tower 6, the acidification reaction tower 7, the fourth synthesis reaction tower 8, the decolorization reaction tower 9, the dilution reaction tower 10, the second centrifugal reaction tower 11, the waste water collection tank 12 , Wastewater treatment system 13, sulfuric acid storage tank 14, ammonia water storage tank 15, intermediate reaction tank 16, potassium chloride solution storage tank 17, finished product storage tank 18; among them, the discharge port of the raw material storage tank 1 is connected to the first In the inlet of the synthesis reaction tower 2, dissolve 2-naphthol in 98% sulfuric acid at 60 degrees Celsius, react for 6 hours, and then add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com