Porous crosslinked polystyrene microsphere and preparation method thereof

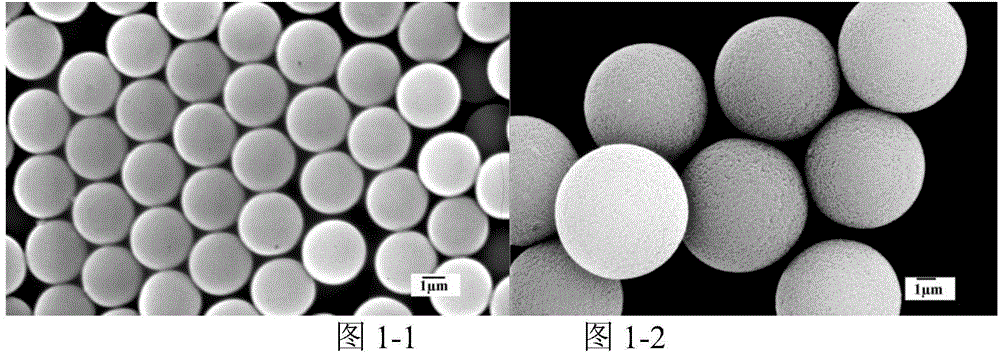

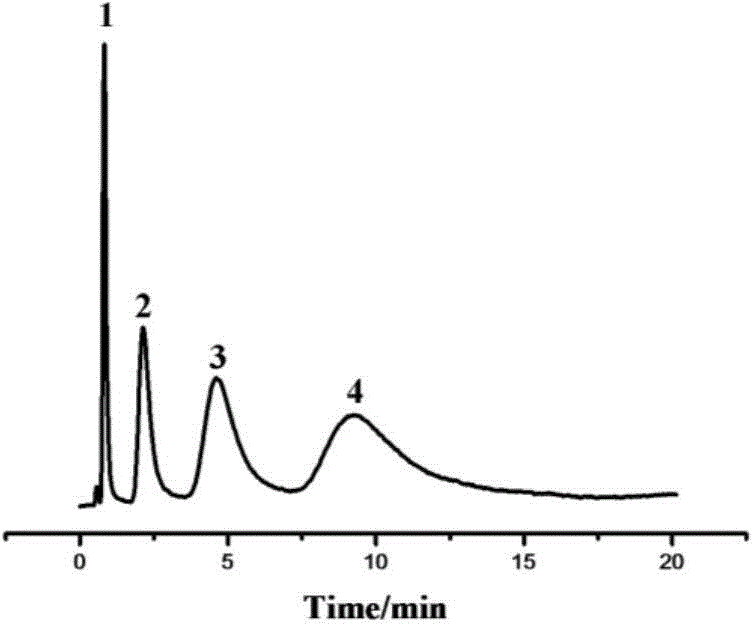

A technology of cross-linked polystyrene and polystyrene, which is applied in the field of monodisperse cross-linked polystyrene microspheres and monodisperse porous cross-linked polystyrene microspheres. Uniform diameter and good monodispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

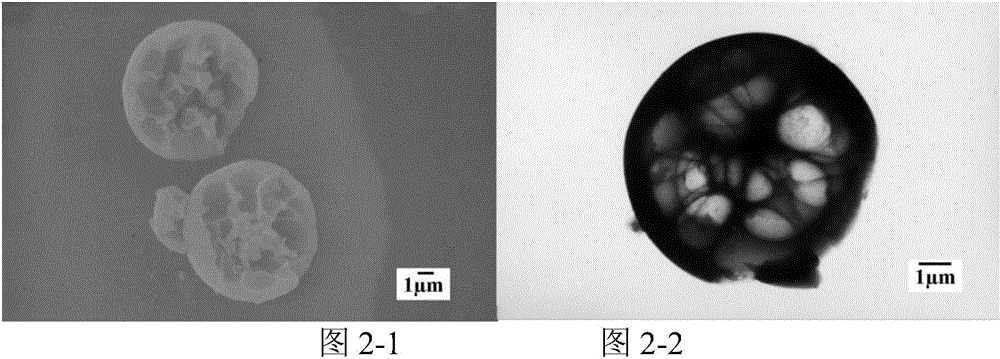

[0046] A kind of porous cross-linked polystyrene microsphere, described porous cross-linked polystyrene microsphere has surface micropore internal macroporous structure, the average pore diameter of described surface micropore is 20.62nm, and the average pore diameter of internal macropore is 1.2 μm.

[0047] The preparation method of the porous cross-linked polystyrene microspheres of the present embodiment comprises the following steps:

[0048] S1. Disperse 0.26 g of monodisperse polystyrene seed microspheres in 30 ml of distilled water to form a seed microsphere solution, add a pore-forming phase to the seed microsphere solution, treat with a cell pulverizer for 30 minutes, and stir for 24 hours to make the The polystyrene seed microspheres are fully swollen to obtain the first swollen product;

[0049] The porogenic phase comprises a mixture of emulsifier sodium dodecyl sulfonate, component A dibutyl phthalate and component B toluene;

[0050] The concentration of each ...

Embodiment 2

[0063] A kind of porous cross-linked polystyrene microsphere, described porous cross-linked polystyrene microsphere has surface micropore internal macroporous structure, the average pore diameter of described surface micropore is 19.45nm, and the average pore diameter of internal macropore is 0.92 μm.

[0064] The preparation method of the porous cross-linked polystyrene microspheres of the present embodiment comprises the following steps:

[0065] S1. Uniformly disperse monodisperse polystyrene seed microspheres in 30 ml of distilled water to form a seed microsphere solution, add a pore-forming phase to the seed microsphere solution, treat with a cell pulverizer for 20 minutes, and stir for 12 hours to make the The polystyrene seed microspheres are fully swollen to obtain the first swollen product;

[0066] The porogenic phase comprises a mixture of emulsifier sodium lauryl sulfate, component A diisobutyl phthalate and component B xylene;

[0067] The concentration of each ...

Embodiment 3

[0078] A kind of porous cross-linked polystyrene microsphere, described porous cross-linked polystyrene microsphere has surface micropore internal macroporous structure, the average pore diameter of described surface micropore is 18.64nm, and the average pore diameter of internal macropore is 1.12 μm.

[0079] The preparation method of the porous cross-linked polystyrene microspheres of the present embodiment comprises the following steps:

[0080] S1. Uniformly disperse monodisperse polystyrene seed microspheres in 30 ml of distilled water to form a seed microsphere solution, add a pore-forming phase to the seed microsphere solution, treat with a cell pulverizer for 40 minutes, and stir for 18 hours to make the The polystyrene seed microspheres are fully swollen to obtain the first swollen product;

[0081] The porogenic phase comprises a mixture of emulsifier sodium dodecyl sulfonate, component A diisobutyl phthalate and component B toluene;

[0082] The concentration of e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com