Soluble polyimide with tert-butyl and triphenylamine structure and preparation method of soluble polyimide

A technology of soluble polyimide and tert-butyl group, which is applied in the field of polyimide, can solve the problems of application limitation, lower glass transition temperature, lower service temperature, etc., and achieve good solubility, good heat resistance, The effect of convenient processing and molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

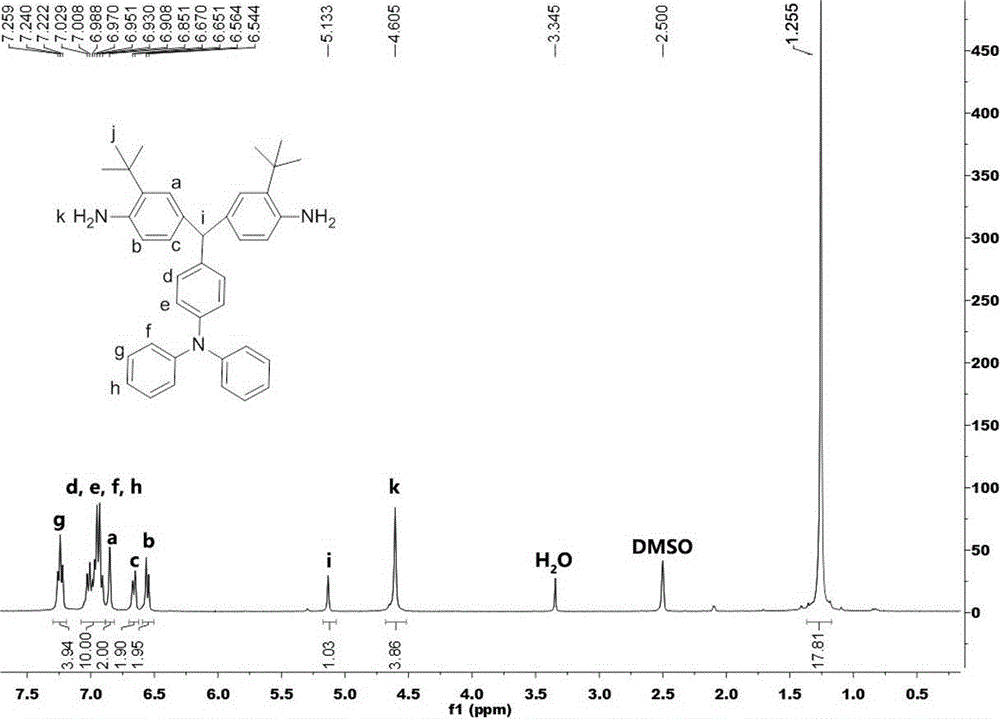

[0039] Embodiment one (synthesis of PI-1):

[0040] The polymerization reaction principle for preparing PI-1 is as follows:

[0041]

[0042] The specific implementation process is as follows:

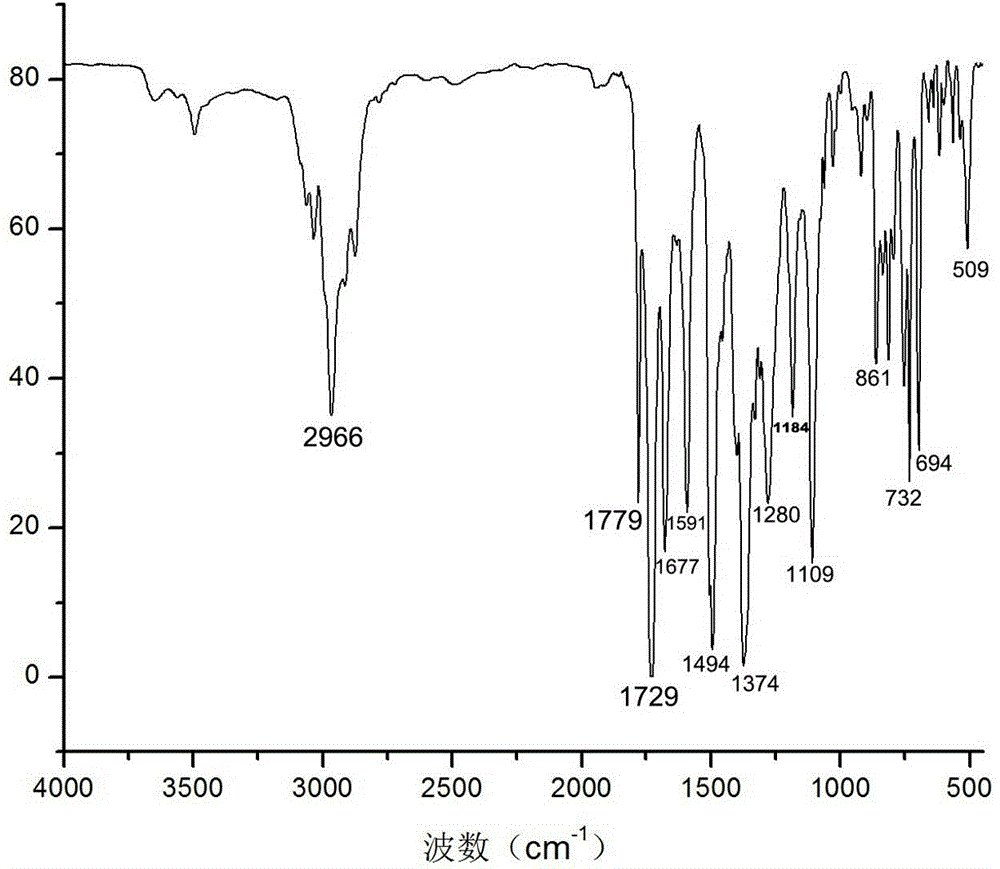

[0043] Under nitrogen protection, add 554mg (1mmol) of the diamine monomer into a 50mL three-necked round-bottomed flask, then add 5mL of m-cresol and 218mg (1mmol) of PMDA in sequence, drop two drops of isoquinoline, and put Stir the reaction for 12 hours to obtain a viscous reaction solution, then raise the temperature to 120° C. and 150° C. and stir the reaction for 5 hours respectively, and finally raise the temperature to 180° C. and continue to stir the reaction for 15 hours. After the reaction solution was cooled to room temperature, 5 mL of chloroform was added to dilute it, and then slowly poured into 200 mL of rapidly stirring methanol, and a white fibrous solid was precipitated. After suction filtration and vacuum drying at 150°C for 24 hours, PI-1 resin was obtained.

...

Embodiment 2

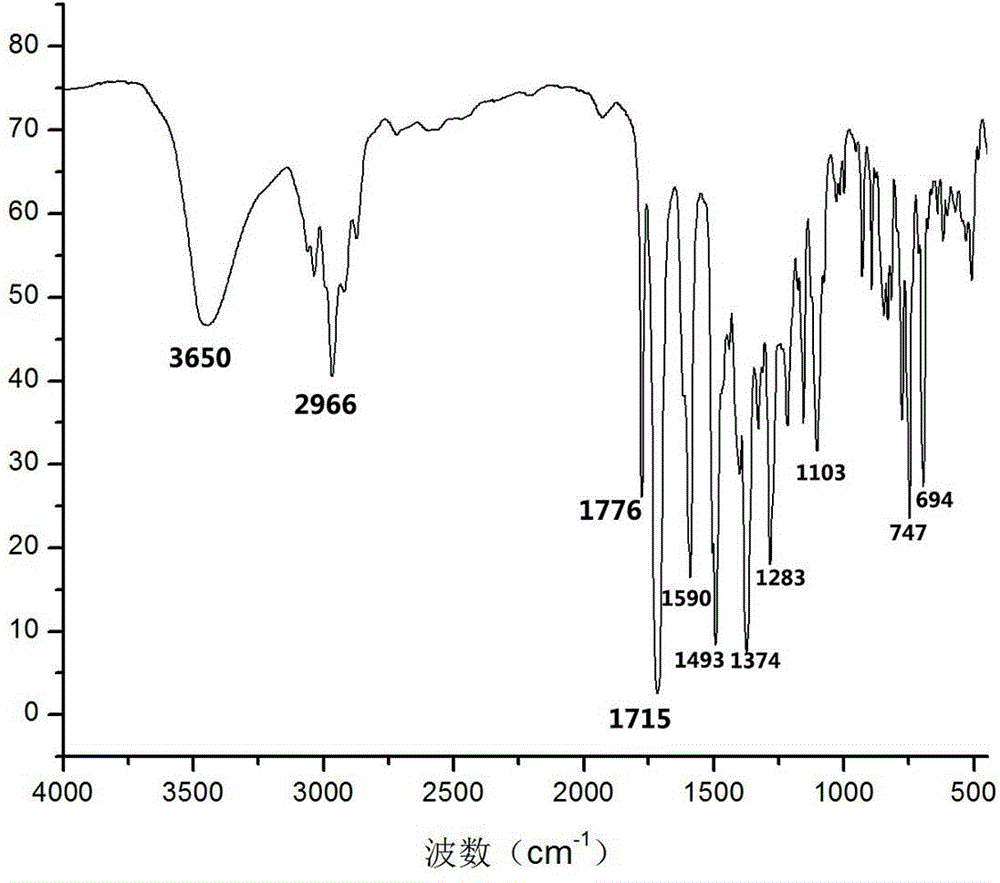

[0046] Embodiment two (synthesis of PI-2):

[0047] The polymerization reaction principle of preparing PI-2 is as follows:

[0048]

[0049] The specific implementation process is as follows:

[0050] Under the protection of nitrogen, add 554mg (1mmol) of the diamine monomer into a 50mL three-neck round-bottomed flask, then add 5mL of m-cresol and 294mg (1mmol) of BPDA in sequence, drop two drops of isoquinoline, at 85°C Stir the reaction for 12 hours to obtain a viscous reaction solution, then raise the temperature to 120° C. and 150° C. respectively, stir and react for 5 hours, and finally raise the temperature to 180° C. and continue to stir and react for 15 hours. After the reaction solution was cooled to room temperature, 5 mL of chloroform was added to dilute it, and then slowly poured into 200 mL of rapidly stirring methanol, and a white fibrous solid was precipitated. After suction filtration and vacuum drying at 150°C for 24 hours, PI-2 resin was obtained.

[00...

Embodiment 3

[0053] Embodiment three (synthesis of PI-3):

[0054] The polymerization reaction principle of preparing PI-3 is as follows:

[0055]

[0056] The specific implementation process is as follows:

[0057] Under nitrogen protection, add 554mg (1mmol) of the diamine monomer into a 50mL three-neck round-bottomed flask, then add 5mL of m-cresol and 310mg (1mmol) of ODPA in sequence, drop two drops of isoquinoline, and put The reaction was stirred for 12 hours to obtain a viscous solution, and then the temperature was raised to 120° C. and 150° C. respectively, and the reaction was stirred for 5 hours, and finally the temperature was raised to 220° C. and the reaction was continued to stir for 15 hours. After the reaction solution was cooled to room temperature, 5 mL of chloroform was added to dilute it, and then slowly poured into 300 mL of rapidly stirring methanol, and a white fibrous solid was precipitated. After suction filtration and vacuum drying at 150°C for 24 hours, PI...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Decomposition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com