Medium-voltage water-tree-retardant crosslinked polyethylene cable material and preparation method thereof

A cross-linked polyethylene and anti-water tree technology, which is applied in the field of medium-voltage anti-water tree cross-linked polyethylene cable materials, can solve the problems of volatile power lines and cables, high cost, poor compatibility, etc., and achieve excellent mechanical and physical properties, The effect of fast crystallization speed and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

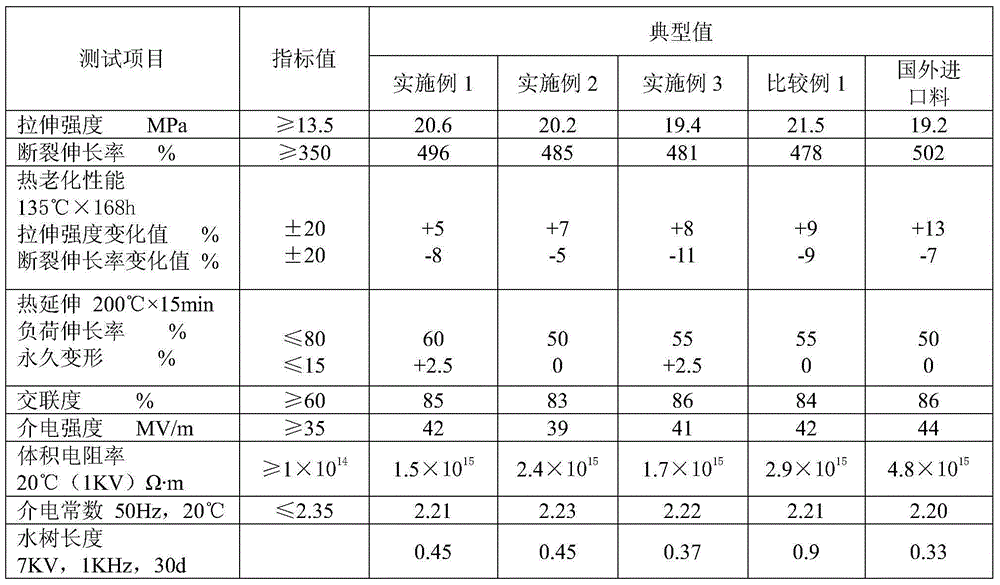

Examples

Embodiment 1

[0023] A) prepare polyvinyl silane grafting material, the melt index that takes by weight is 80 parts of low-density polyethylenes of 1.8g / 10min earlier, vinyl-three (2-methoxyethoxy) silane 5 1 part, 0.1 part of dicumyl peroxide and 2 parts of 4,4'-thiobis(6-tert-butyl-3-methylphenol) were put into a stirring container for pre-mixing, and the speed of the stirring container was controlled at 200r / min , the time control of premixing is 8min, obtains polyvinyl silane mixture, then this polyvinyl silane mixture is fed into (that is, fed into) twin-screw extruder by metering pump for example by Brabender metering system and carries out grafting Extrude (the graft extrusion mentioned here is the plasticizing extrusion, the following embodiment 2 and 3 are the same example), the rotating speed control of twin-screw extruder graft extrusion is 245r / min, and twin-screw The extrusion temperature of the extruder is from the first zone to the eighth zone, and the temperature of the mach...

Embodiment 2

[0027] A) prepare polyvinyl silane grafting material, the melt index that takes by weight is 90 parts of low density polyethylene of 2.2g / 10min, vinyl-three (2-methoxyethoxy) silane 3 part, 0.1 part of dicumyl peroxide, 0.1 part of dicumyl peroxide, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester 1 0.5 parts of β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate and 0.5 parts of dilauryl thiodipropionate are put into the stirring container for pre-mixing, and the stirring container The rotating speed control is 300r / min, the time control of premixing is 5min, obtains polyvinyl silane mixture, then this polyvinyl silane mixture is fed to (that is, fed to) twin-screw by metering pump such as by Brabender metering system Carry out graft extruding in the extruder, the rotational speed control of twin-screw extruder graft extruding is 215r / min, and the extruding temperature of twin-screw extruder is from one district to eight districts, mac...

Embodiment 3

[0031] A) prepare polyvinyl silane grafting material, the melt index that takes by weight is 85 parts of low-density polyethylenes of 2g / 10min, 4 parts of vinyl-three (2-methoxyethoxy) silanes , 0.15 parts of diisophenyl peroxide and 3 parts of 4,4'-thiobis(6-tert-butyl-3-methylphenol) were put into a stirring container for pre-mixing, and the speed of the stirring container was controlled at 250r / min. The time of mixing is controlled to be 6.5min, obtains polyvinyl silane mixture, then this polyvinyl silane mixture is fed into (that is, fed into) twin-screw extruder by metering pump and carry out graft extruding as by Brabender metering system , the speed of graft extrusion of the twin-screw extruder is controlled to be 230r / min, and the extrusion temperature of the twin-screw extruder is controlled from the first zone to the eighth zone, and the temperature of the machine neck and the head is respectively controlled to be 120°C in the first zone , the second zone is 135°C, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com