Negative electrode of carbon-composite Cu3P-Cu lithium-ion battery and preparation method of negative electrode

A lithium-ion battery, cu3p-cu technology, which is applied in the field of electrochemical power supply, and achieves the effect of simple and novel synthesis method, easy operation and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Cu 3 The specific steps of the preparation method of P / C-Cu are:

[0024] (1) Clean the surface of foamed copper (Changsha Liyuan New Materials Co., Ltd.) with hydrochloric acid with a concentration of 10-30% to remove oxides on the surface;

[0025] (2) Dissolve citric acid (Sinopharm Group) in deionized water to form a uniform solution with a concentration of 2g / L; completely immerse the foamed copper in step (1) in the solution;

[0026] (3) Place the copper foam adsorbed with citric acid in step (2) in a vacuum oven and dry at 50°C; weigh 2g of red phosphorus (Sinopharm) with a purity of 98% and spread it on a ceramic boat with a thickness of 1.0 ~3.0mm; then place the dried copper foam (separated by foam copper fines) on top of the red phosphorus, and sinter at 350°C for 3h under the protection of nitrogen.

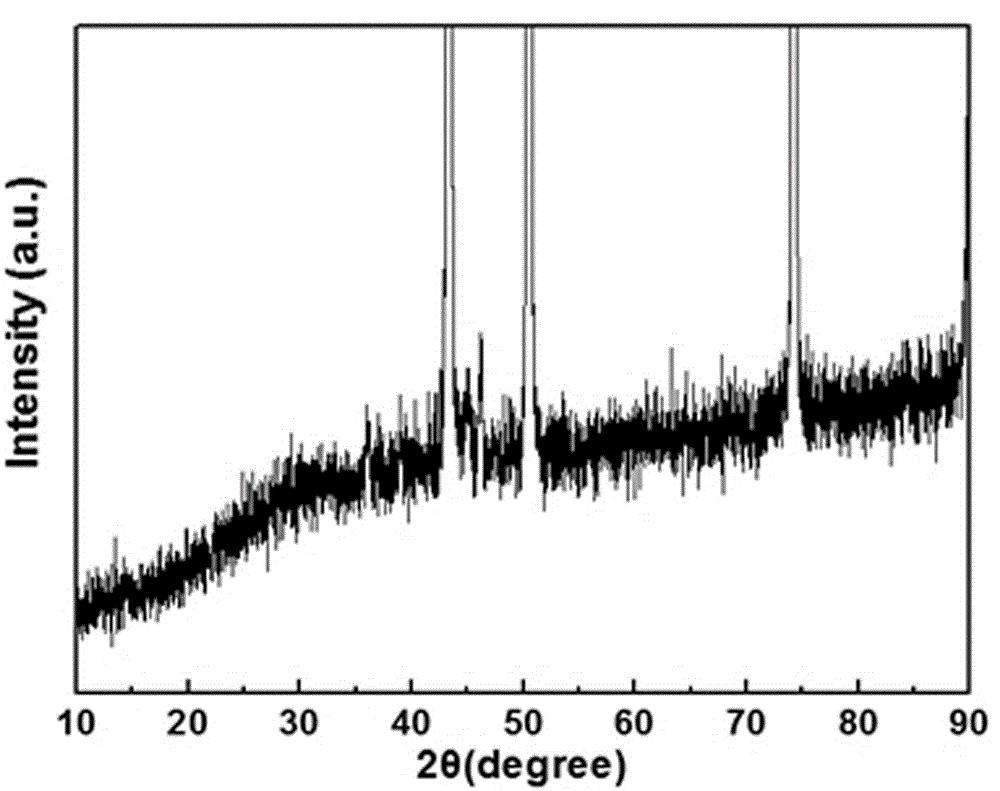

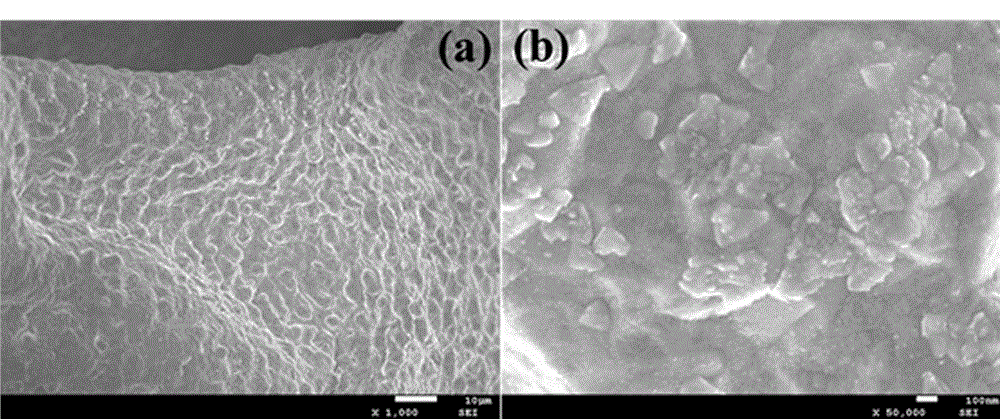

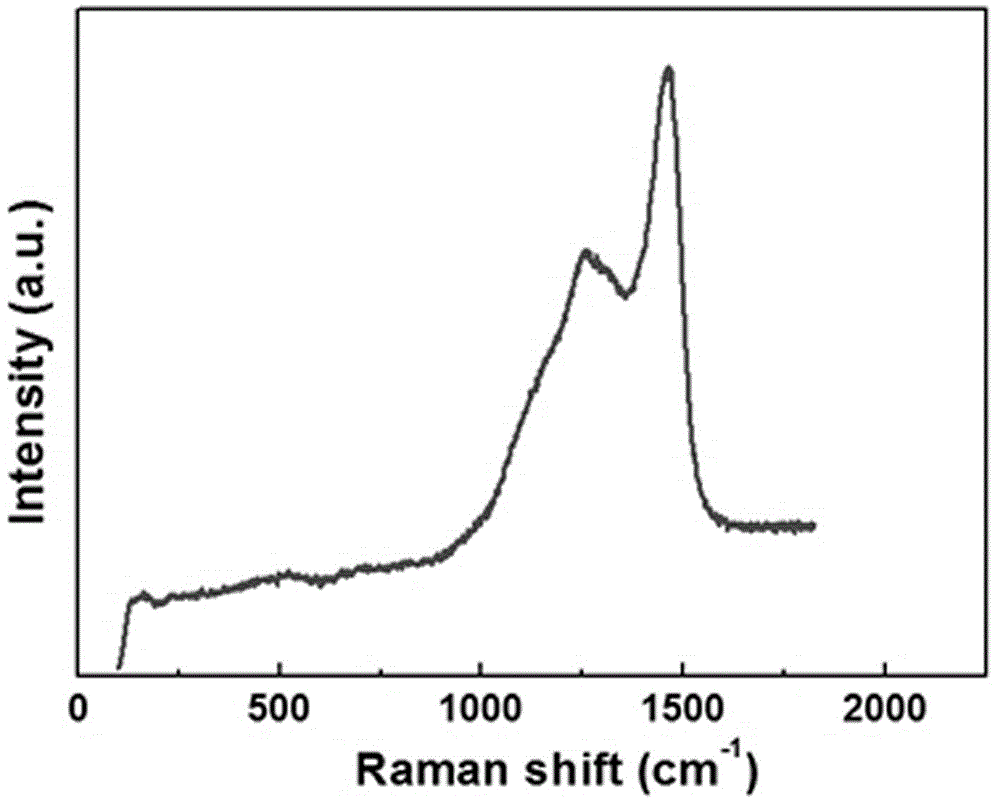

[0027] figure 1 The XRD pattern analysis of the prepared sample can correspond to Cu 3 Diffraction peaks of P and copper foam. The obtained samples were...

Embodiment 2

[0029] Cu 3 The specific steps of the preparation method of P / C-Cu are:

[0030] (1) Clean the surface of foamed copper (Changsha Liyuan New Materials Co., Ltd.) with hydrochloric acid with a concentration of 10-30% to remove oxides on the surface;

[0031] (2) Dissolve glucose (Sinopharm Group) in deionized water to form a uniform solution with a concentration of 2g / L; completely immerse the foam copper in step (1) in the solution;

[0032] (3) Put the glucose-adsorbed copper foam in step (2) in a vacuum oven and dry at 50°C; weigh 2g of red phosphorus (Sinopharm) with a purity of 98% and spread it on a ceramic boat with a thickness of 1.0~ 3.0mm; then place the dried copper foam (separated by copper foam fines) on top of the red phosphorus, and sinter at 350°C for 3 hours under the protection of nitrogen. Cu obtained by the above steps 3 The P / C-Cu negative electrode was cut into 14mm discs and dried in vacuum at 120°C for 12h. Lithium metal sheet is used as the counter ...

Embodiment 3

[0034] Cu 3 The specific steps of the preparation method of P / C-Cu are:

[0035] (1) Clean the surface of foamed copper (Changsha Liyuan New Materials Co., Ltd.) with hydrochloric acid with a concentration of 10-30% to remove oxides on the surface;

[0036] (2) Dissolve sucrose (Sinopharm Group) in deionized water to form a uniform solution with a concentration of 2g / L; completely immerse the foamed copper in step (1) in the solution;

[0037] (3) Place the copper foam adsorbed on sucrose in step (2) in a vacuum oven at 50°C to dry; weigh 2g of red phosphorus (Sinopharm) with a purity of 98% and spread it on a ceramic boat with a thickness of 1.0~ 3.0mm; then place the dried copper foam (separated by copper foam fines) on top of the red phosphorus, and sinter at 350°C for 3 hours under the protection of nitrogen. Cu obtained by the above steps 3 The P / C-Cu negative electrode was cut into 14mm discs and dried in vacuum at 120°C for 12h. Lithium metal sheet is used as the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com