3D lead-acid battery and production method thereof

A technology of lead-acid battery and manufacturing method, which is applied in the direction of lead-acid battery, lead-acid battery construction, and final product manufacturing, and can solve the problems of low conversion of chemical energy into effective electric energy, high calorific value of grids and active materials, and chemical formation and low charge and discharge efficiency, to achieve the effect of high utilization of active materials, small internal resistance, high formation and charge and discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

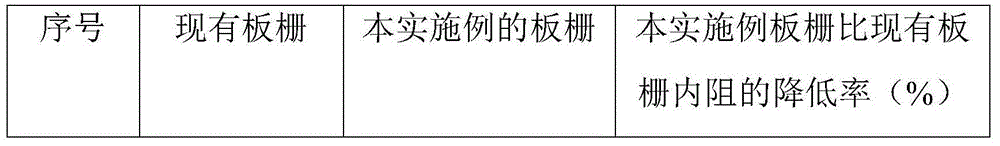

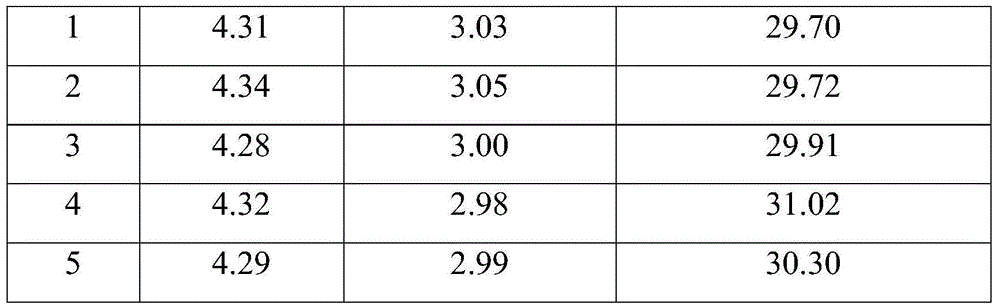

[0046] The 3D lead-acid battery of the present invention includes an electrolytic cell, and the electrolytic cell contains H with a mass fraction of 35.6%. 2 SO 4 solution, the two ends of the electrolytic cell have an anode plate and a cathode plate, the anode plate is connected with the anode of the power supply, the cathode plate is connected with the cathode of the power supply, both the anode plate and the cathode plate include a grid, the grid is lead foil, and the lead foil is cold Rolled lead foil, the lead foil is corrugated, and there are many evenly distributed through holes on the lead foil. The cross-sectional area of the through holes is square. Of course, rectangles, rhombuses, etc. are also within the protection scope of the present invention. The side length of the square is 1mm, the distance between two adjacent through holes is 0.4mm, and there is a layer of lead-tin alloy mesocrystalline layer on the surface of the lead foil. The upper and lower surfaces...

Embodiment 3

[0083] The difference between the structure of the 3D lead-acid battery of this embodiment and the first embodiment is that the side length of the square is 4 mm, the distance between adjacent through holes is 1.2 mm, and the rest is the same as the first embodiment.

[0084] The difference between the manufacturing method of the lead-acid battery of the present embodiment and the first embodiment is that the side length of the square pattern in step (3) is 4mm, and the distance between adjacent squares is 1.2mm; The composition and proportion of the solution are as follows: 1L of lead methanesulfonate electrolytic solution with a mass fraction of 50%, 50mL of glutaraldehyde, 100mL of benzaldehyde, 100mL of cocoa diethanolamine, 5mL of oxyethylated fatty acid; the electroplating time is 50 minutes; the steps The time of drying and solidifying in (8) is 12h, and all the other are identical with embodiment one.

[0085] After measurement, the specific surface area of the 3D le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap