Preparation method of gold nanoparticles

A technology of nano-gold particles and nano-gold colloids, which is applied in electricity, can solve the problems of long time, high cost, and easy aggregation of nano-gold particles, and achieve the effects of simple operation, high uniformity and good particle dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

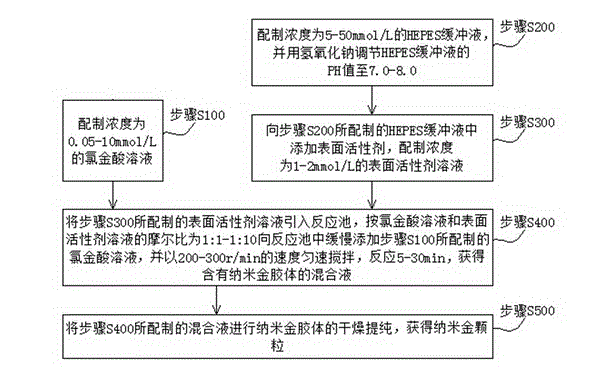

[0053] A kind of preparation method of nano gold particles of the present embodiment, such as figure 1 Shown, mainly realize through following technical scheme: comprise the following steps:

[0054] Step S100: Prepare a chloroauric acid solution with a concentration of 0.05-10 mmol / L;

[0055] Step S200: preparing a HEPES buffer solution with a concentration of 5-50 mmol / L, and adjusting the pH value of the HEPES buffer solution to 7.0-8.0 with sodium hydroxide;

[0056] Step S300: adding a surfactant to the HEPES buffer prepared in step S200 to prepare a surfactant solution with a concentration of 1-2 mmol / L;

[0057] Step S400: introduce the surfactant solution prepared in step S300 into the reaction tank, slowly add the chlorine prepared in step S100 into the reaction tank according to the molar ratio of the chloroauric acid solution and the surfactant solution in the range of 1:1-1:10 Auric acid solution, stirred at a constant speed of 200-300r / min, reacted for 5-30min,...

Embodiment 2

[0061] This embodiment is further optimized on the basis of the above embodiments. Further, the surfactant solution in step S300 refers to the PVP solution. Other parts of this embodiment are the same as those of the foregoing embodiments, so details are not repeated here.

Embodiment 3

[0062] Embodiment 3: This embodiment is further optimized on the basis of Embodiment 2. Further, the step S100 specifically refers to: preparing a chloroauric acid solution with a concentration of 1 mmol / L;

[0063] The step S200 specifically refers to: preparing a HEPES buffer solution with a concentration of 20 mmol / L, and adjusting the pH value of the HEPES buffer solution to 7.4 with sodium hydroxide;

[0064] The step S300 specifically refers to: adding a surfactant to the HEPES buffer prepared in the step S200 to prepare a surfactant solution with a concentration of 1 mmol / L;

[0065] The step S400 specifically refers to: under normal temperature, the surfactant solution prepared in step S300 is introduced into the reaction tank, and the molar ratio of the chloroauric acid solution and the surfactant solution is 1:5-1:10 into the reaction tank. Slowly add the chloroauric acid solution prepared in step S100, and stir at a speed of 250r / min for 10min to obtain a mixed solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com