Mixed-valence-state europium (Eu) ion doped single-matrix color-adjustable fluorescent powder and preparation method thereof

A technology of mixed valence and phosphor, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of low luminous efficiency, affecting the luminous performance of three primary color phosphors, and reducing the performance of white LEDs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Weigh europium oxide (Eu 2 o 3 ) 0.0176g, calcium carbonate (CaCO 3 ) 1.9918g, silicon dioxide (SiO 2 ) 0.6008g, ammonium fluoride (NH 4 F) 0.7408g was thoroughly ground in an agate mortar and mixed evenly, then calcined in a carbon monoxide reducing atmosphere, sintered at 900°C for 6 hours, and cooled naturally to room temperature. The sample is taken out and ground, and finally the product is obtained, and the composition of the fluorescent powder material is: Ca 1.99 Eu 0.01 SiO 2 f 2 .

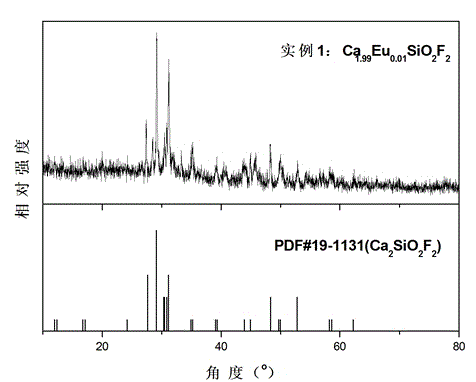

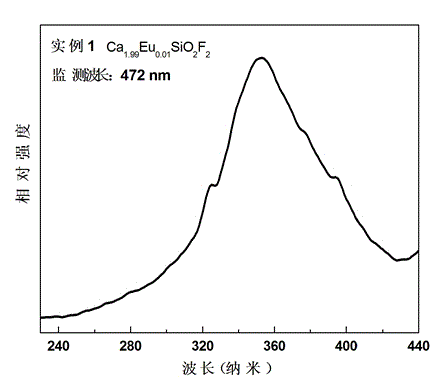

[0025] The diffraction peak position of the obtained phosphor material is consistent with that of the crystallographic database PDF#19-1131, indicating that the material structure and matrix Ca 2 SiO 2 f 2 agree, see figure 1 . figure 2 For the excitation spectrum of the material of this embodiment, from figure 2 It can be seen that the phosphor material of the present invention can be effectively excited by 320nm-420nm near ultraviolet light. The phosphor material ...

Embodiment 2

[0027] Weigh europium oxide (Eu 2 o 3 ) 0.0528g, calcium carbonate (CaCO 3 ) 1.9717g, silicon dioxide (SiO 2 ) 0.6008g, ammonium fluoride (NH 4 F) 0.7408g was thoroughly ground in an agate mortar and mixed evenly, then calcined in a carbon monoxide reducing atmosphere, sintered at 900°C for 6 hours, and cooled naturally to room temperature. The sample is taken out and ground, and finally the product is obtained, and the composition of the fluorescent powder material is: Ca 1.99 Eu 0.03 SiO 2 f 2 .

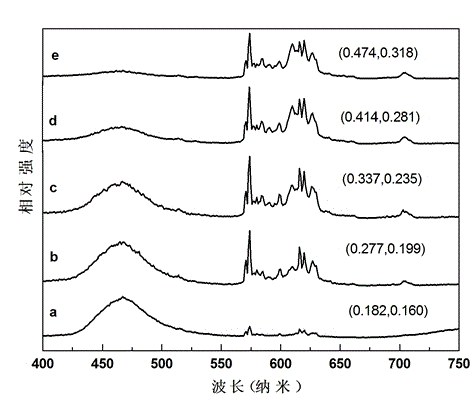

[0028] Under the excitation of 355nm near-ultraviolet light, the phosphor material of the present invention, trivalent Eu 3+ Red-emitting sharp edge and divalent Eu 2+ The blue light emission broadband intensity ratio increases, see appendix image 3 -b; color coordinates are (0.277, 0.199), see attached Figure 4 -b.

Embodiment 3

[0030] Weigh europium oxide (Eu 2 o 3 ) 0.0880g, calcium carbonate (CaCO 3 ) 1.9518g, silicon dioxide (SiO 2 ) 0.6008, ammonium fluoride (NH 4 F) 0.7408g was thoroughly ground in an agate mortar and mixed evenly, then calcined in a carbon monoxide reducing atmosphere, sintered at 900°C for 6 hours, and cooled naturally to room temperature. The sample is taken out and ground, and finally the product is obtained, and the composition of the fluorescent powder material is: Ca 1.99 Eu 0.05 SiO 2 f 2 .

[0031] Under the excitation of 355nm near-ultraviolet light, the phosphor material of the present invention, trivalent Eu 3+ Red-emitting sharp edge and divalent Eu 2+ The blue light emission broadband intensity ratio continues to increase, see appendix image 3 -c; color coordinates are (0.337, 0.235), see attached Figure 4 -c.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com