Aluminum-copper-iron quasi-crystal and silicon carbide mixed enhanced aluminum-based composite preparation method

一种铝基复合材料、碳化硅的技术,应用在铸造成型设备、铸型、型芯等方向,能够解决工艺技术有待提高等问题,达到工艺先进、数据精确翔实、工序严密的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with accompanying drawing:

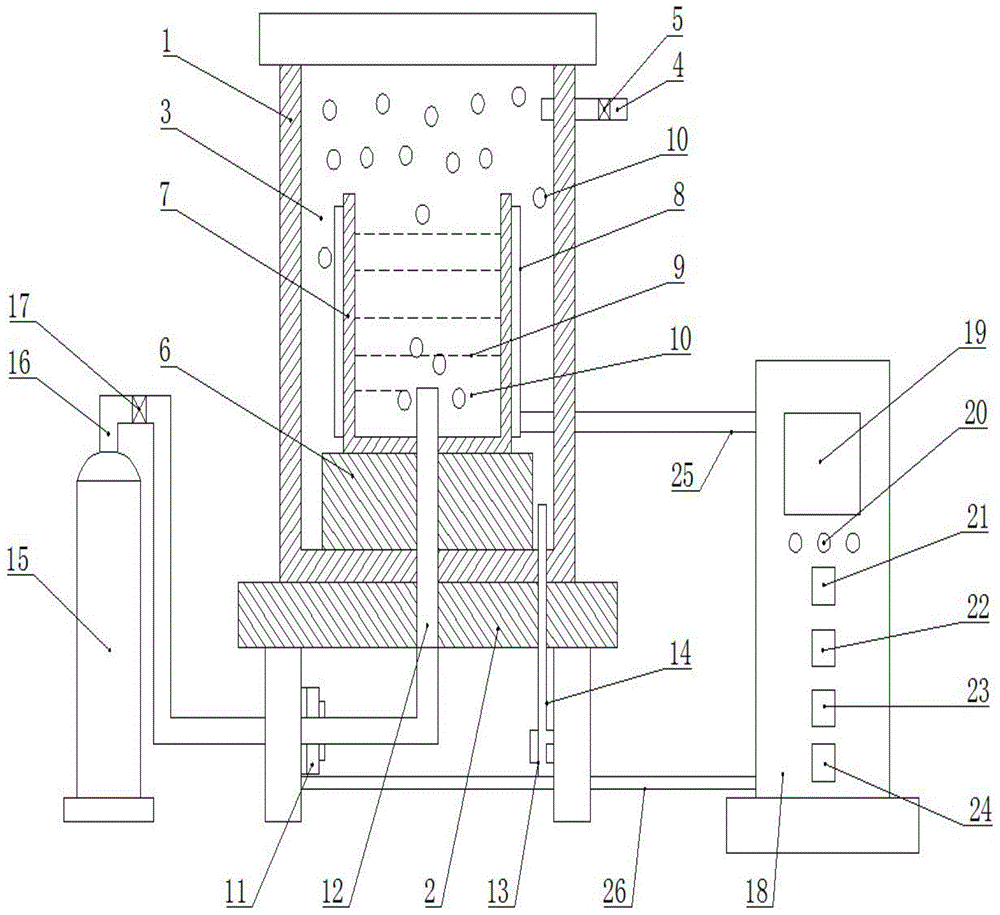

[0064] figure 1 As shown, it is the smelting state diagram of aluminum-copper-iron quasicrystal and silicon carbide mixed reinforced aluminum matrix composite material. The position of each part must be correct, the ratio should be adjusted, and the operation should be done in sequence.

[0065] The amount of chemical substances used in the preparation is determined according to the pre-set range in grams, milliliters, centimeters3 is the unit of measurement.

[0066] The smelting of aluminum-copper-iron quasicrystal and silicon carbide mixed reinforced aluminum matrix composite material is carried out in an intermediate frequency induction melting furnace, which is completed in the process of intermediate frequency induction heating, vacuuming, argon bottom blowing, and casting;

[0067] The intermediate frequency induction melting furnace is vertical. The bottom of the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com