Preparation method of manganic manganous oxide/ carbon matrix composite nanoelectrode material

A technology of trimanganese tetraoxide and nano-electrode, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems affecting the specific capacitance and energy density of supercapacitors, and the increase of internal resistance of electrode materials, so as to improve the electric capacity. Chemical properties, improved electrical conductivity and stability, good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: The carbonization heating rate is 1° C. / min.

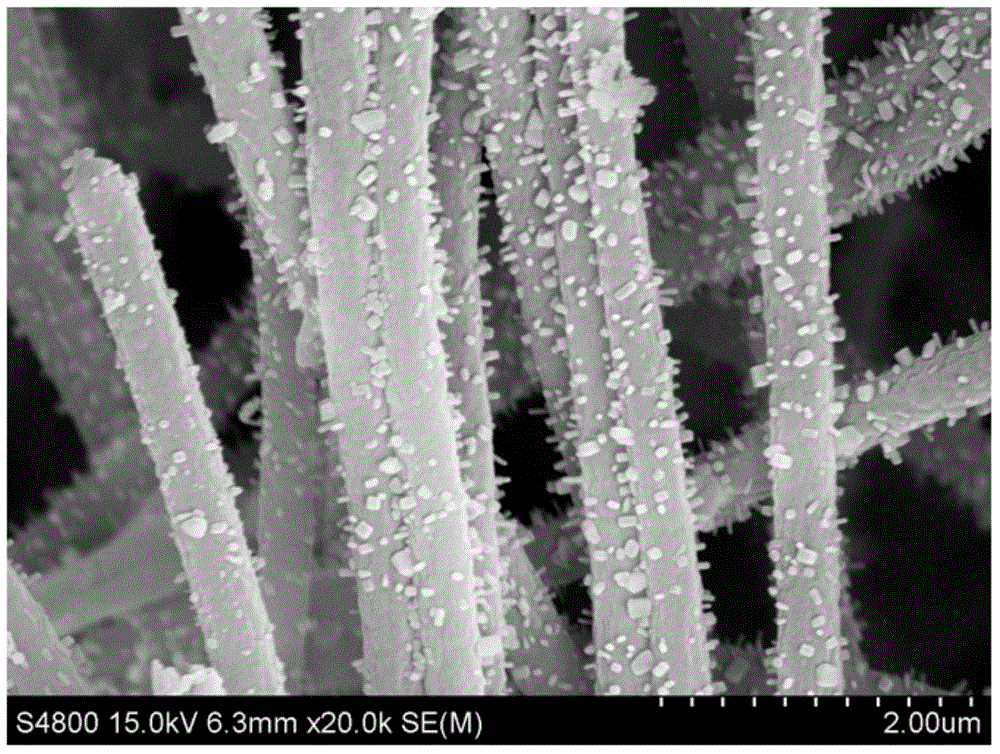

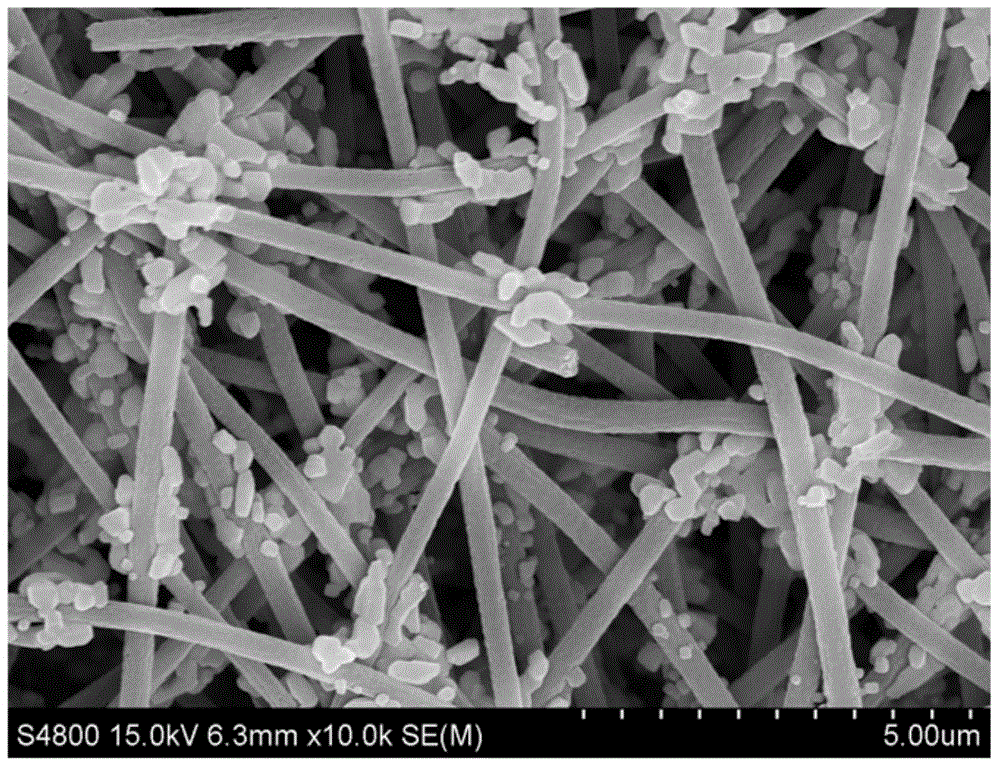

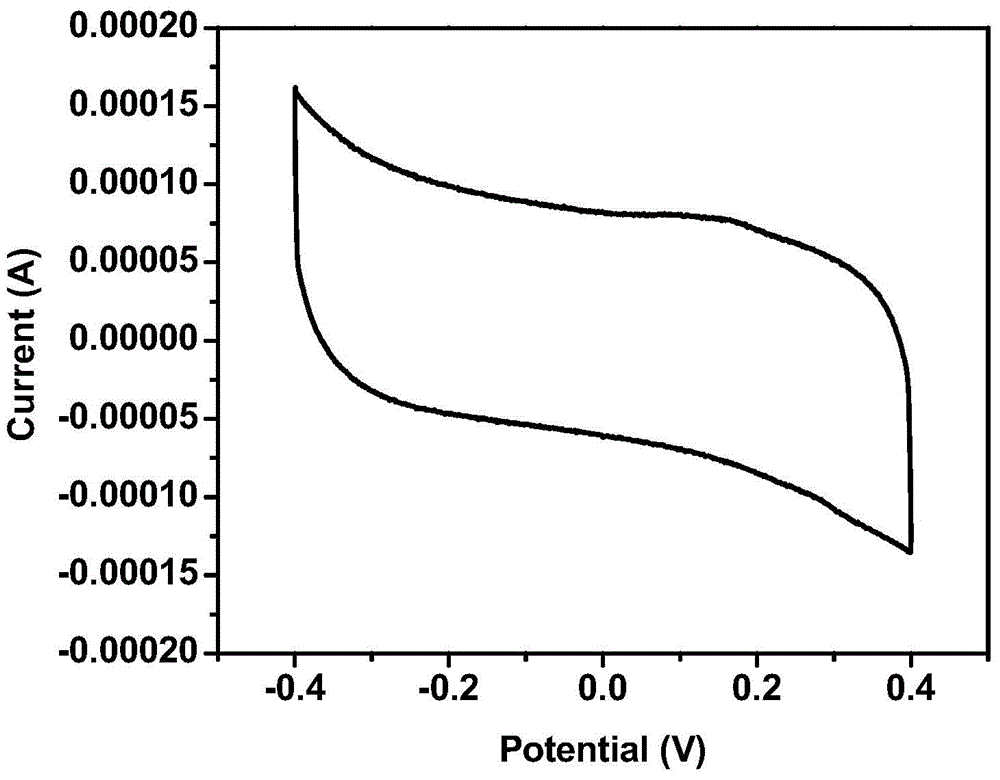

[0022] Weigh 0.6g of manganese acetate and put it into 18g of N,N-dimethylformamide, stir and dissolve, weigh 2g of polyacrylonitrile into the dissolved solution, stir until the solution is transparent and clear, and obtain spinning solution. The spinning solution is electrospun under the conditions that the spinning voltage is 15kV, the receiving distance is 20cm, the flow rate of the spinning solution is 0.1mm / min, and the inclination angle of the injector is 15°, and the fiber diameter is (500-800) nm 30% Mn / PAN composite nanofibers, the fiber was heated up to 280°C at a heating rate of 5°C / min, pre-oxidized in air, kept at a constant temperature for 1h, and the pre-oxidized fiber was heated at a heating rate of 1°C / min The temperature was raised to 1000° C., carbonization was carried out in nitrogen, and the temperature was kept constant for 1 hour to obtain Mn / C composite nanofibers with a diameter of (300-...

Embodiment 2

[0024] Example 2: The carbonization heating rate is 3° C. / min.

[0025] Weigh 1.2g of manganese acetate and put it into 36g of N,N-dimethylformamide. After stirring and dissolving, weigh 4g of polyacrylonitrile into the dissolved solution, stir until the solution is transparent and clear, and obtain spinning solution. The spinning solution is electrospun under the condition that the spinning voltage is 18kV, the receiving distance is 20cm, the flow rate of the spinning solution is 0.15mm / min, and the inclination angle of the injector is 15°, and the fiber diameter is (600-800) nm of 30% Mn / PAN composite nanofibers, the fiber was heated up to 280°C at a heating rate of 5°C / min, pre-oxidized in air, kept at a constant temperature for 1.5h, and the pre-oxidized fiber was heated at a rate of 3°C / min The temperature was raised to 1000° C., carbonized in nitrogen, and kept at a constant temperature for 1.5 hours to obtain Mn / C composite nanofibers with a diameter of (350-450) nm. ...

Embodiment 3

[0027] Example 3: The carbonization heating rate is 5° C. / min.

[0028] Weigh 0.6g of manganese acetate and put it into 18g of N,N-dimethylformamide, stir and dissolve, weigh 2g of polyacrylonitrile into the dissolved solution, stir until the solution is transparent and clear, and obtain spinning solution. The spinning solution is electrospun under the condition that the spinning voltage is 20kV, the receiving distance is 20cm, the flow rate of the spinning solution is 0.2mm / min, and the inclination angle of the injector is 15°, and the obtained fiber diameter is (500-700) nm of 30% Mn / PAN composite nanofibers, the fiber was heated up to 280°C at a heating rate of 5°C / min, pre-oxidized in air, and kept at a constant temperature for 2 hours, and the pre-oxidized fiber was heated at a heating rate of 5°C / min The temperature was raised to 1000° C., carbonization was carried out in nitrogen, and the temperature was kept constant for 2 hours to obtain Mn / C composite nanofibers wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com