Oat and wheat premixed steamed bread flour and a production method thereof

A technology of pre-mixing and steamed bread powder, which is applied in application, food preparation, food science, etc., can solve the problems of less addition of oat flour and unstable product quality, and meet the needs of rich oat fragrance, convenient consumption and increased nutritional value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: oat wheat premixed steamed bread powder is made by mixing oat flour, wheat flour and additives according to the weight ratio of 30:100:4-5, and the additives are composed of yeast, sucrose fatty acid ester, sodium alginate, monoglyceride , sodium bicarbonate and sugar are mixed according to the weight ratio of 1:0.6:0.5:0.4:0.2:2.0.

[0024] The production method of the above-mentioned oat wheat premixed steamed bread powder comprises the following steps:

[0025] (1) Yeast, sucrose fatty acid ester, sodium alginate, monoglyceride, sodium bicarbonate and sugar are uniformly mixed according to the weight ratio of 1:0.6:0.5:0.4:0.2:2.0 to make an additive;

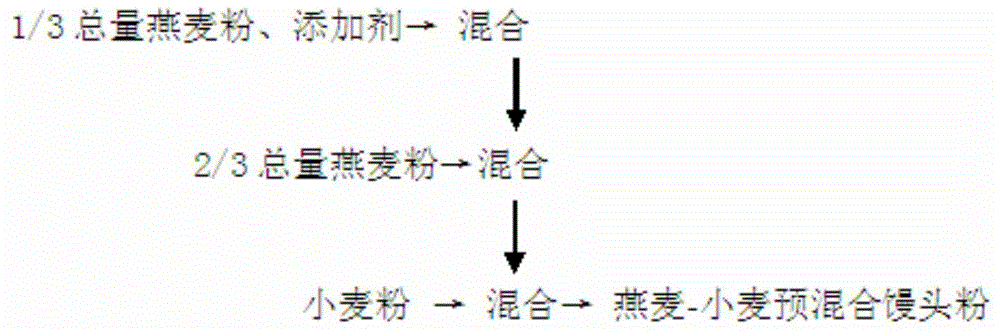

[0026] (2) Stir and mix the additive and 1 / 3 of the total amount of oat flour; then add the remaining 2 / 3 of the total amount of oat flour and stir and mix evenly;

[0027] (3) Add wheat flour and mix well, the weight ratio of oat flour, wheat flour and additives is 30:100:4-5.

[0028] The production pro...

Embodiment 2

[0037] Embodiment 2: form by mixing oat flour, wheat flour and additive according to weight ratio 30:100:4-5, described additive is made of yeast, sucrose fatty acid ester, sodium alginate, monoglyceride, sodium bicarbonate and sugar It is mixed according to the weight ratio of 1:0.6:0.5:0.4:0.2:2.0.

[0038] Production method of the present invention comprises the following steps:

[0039] (1) Yeast, sucrose fatty acid ester, sodium alginate, monoglyceride, sodium bicarbonate and sugar are uniformly mixed according to the weight ratio of 1:0.6:0.5:0.4:0.2:2.0 to make an additive;

[0040] (2) Stir and mix the additive and 1 / 3 of the total amount of oat flour; then add the remaining 2 / 3 of the total amount of oat flour and stir and mix evenly;

[0041] (3) Add wheat flour and mix well, the weight ratio of oat flour, wheat flour and additives is 30:100:4-5.

[0042] The production process of oat wheat premixed steamed bread powder is as follows: figure 1 shown.

[0043] In ...

Embodiment 3

[0051] Embodiment 3: form by mixing oat flour, wheat flour and additive according to weight ratio 30:100:4-5, described additive is made of yeast, sucrose fatty acid ester, sodium alginate, monoglyceride, sodium bicarbonate and sugar It is mixed according to the weight ratio of 1:0.6:0.2:0.1:0.2:2.0.

[0052] Production method of the present invention comprises the following steps:

[0053] (1) Yeast, sucrose fatty acid ester, sodium alginate, monoglyceride, sodium bicarbonate and sugar are uniformly mixed according to the weight ratio of 1:0.6:0.2:0.1:0.2:2.0 to make an additive;

[0054] (2) Stir and mix the additive and 1 / 3 of the total amount of oat flour; then add the remaining 2 / 3 of the total amount of oat flour and stir and mix evenly;

[0055] (3) Add wheat flour and mix well, the weight ratio of oat flour, wheat flour and additives is 30:100:4-5.

[0056] The production process of oat wheat premixed steamed bread powder is as follows: figure 1 shown.

[0057] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com