Amphipathic polysaccharide derivative/poloxamer thermo-sensitive type in-situ hydrogel and preparation method thereof

A technology of amphiphilic polysaccharides and poloxamers, which is applied in the field of biomedical materials, can solve the problems that the properties of poloxamer thermosensitive hydrogels are greatly affected, and there are few studies, so as to improve the bioavailability of drugs, Effect of increasing gelation temperature, good biocompatibility and degradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

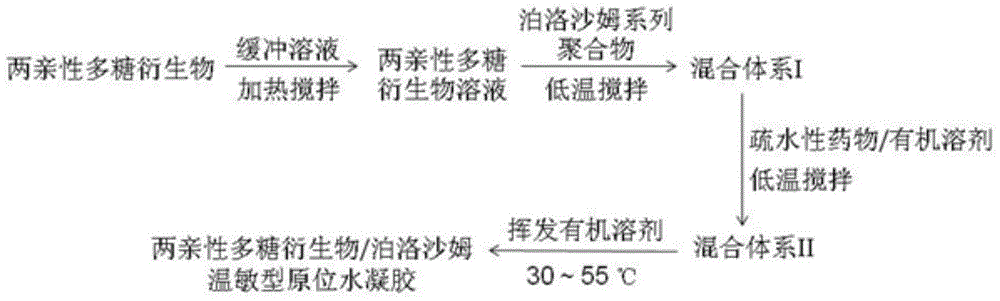

[0041] 1. Preparation method

[0042] (1) Weigh 10 mg of the amphiphilic sodium alginate derivative containing cholesterol group, put it in a serum bottle, add 1 ml of disodium hydrogen phosphate-sodium dihydrogen phosphate buffer (pH 7.4), and at 45 ℃ Stir (rotation speed 300 r / min) to dissolve for 12 hours to obtain amphiphilic sodium alginate derivative solution;

[0043] (2) Weigh 126 mg of poloxamer 407 and 10 mg of poloxamer 188 respectively, put them in a stoppered test tube, add the amphiphilic sodium alginate derivative solution obtained in step S1, and stir at 4°C (rotation speed 300 rpm) / min) dissolved for 12 hours to obtain Mixed System I;

[0044] (3) Weigh 20 mg of prednisone, put it in a serum bottle, add 2 ml of acetone, stir and dissolve at room temperature for 10 minutes, slowly add it dropwise (drop rate 30 drops / min) to the mixed system I obtained from S2, stir at 8°C ( Rotation speed 300 rpm) and dissolved for 12 hours to obtain Mixed System II;

[004...

Embodiment 2

[0055] 1. Preparation method

[0056] (1) Weigh 60 mg of amphiphilic hyaluronic acid derivative containing cholesterol group, put it in a serum bottle, add 5 ml of citric acid-sodium citrate buffer (pH 7.2), and stir at 25°C (rotation speed) 100 rpm) for 24 hours to obtain amphiphilic hyaluronic acid derivative solution;

[0057] (2) Weigh 100 mg of poloxamer 407 and 70 mg of poloxamer 338 respectively, put them in a test tube with a stopper, add the solution of the amphiphilic hyaluronic acid derivative obtained in step S1, and stir at 8°C (rotation speed 100 rpm) / min) dissolved for 36 hours to obtain Mixed System I;

[0058] (3) Weigh 1 mg of indomethacin, put it in a serum bottle, add 1 ml of ethanol, stir and dissolve at room temperature for 25 minutes, slowly add it dropwise (drop rate 10 drops / min) to the mixed system I obtained from S2, stir at 10 °C (Rotation speed 100 rpm) and dissolved for 12 hours to obtain Mixed System II;

[0059] (4) The mixed system II obtai...

Embodiment 3

[0064] 1. Preparation method

[0065] (1) Weigh 130 mg of the amphiphilic pullulan derivative containing cholesterol group, put it in a serum bottle, add 8 ml of disodium hydrogen phosphate-sodium dihydrogen phosphate buffer solution (pH 7.4), at 38 ℃ stirring (rotation speed 1000 r / min) to dissolve for 24 hours to obtain amphiphilic pullulan derivative solution;

[0066] (2) Weigh 267 mg of poloxamer 407 and 26 mg of poloxamer 108 respectively, put them in a stoppered test tube, add the amphiphilic pullulan derivative solution obtained in step S1, and stir at 15°C (rotation speed 1000 rev / min) to dissolve for 24 hours to obtain Mixed System I;

[0067] (3) Weigh 38 mg of triamcinolone acetonide acetate, put it in a serum bottle, add 8 ml of acetone, stir and dissolve at room temperature for 15 minutes, slowly add it dropwise (drop rate 40 drops / min) to the mixed system I obtained from S2, stir at 12°C (Rotation speed 1000 rpm) and dissolved for 36 hours to obtain Mixed Syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com