Method for preparing nano aluminum nitride material through electrical explosion process

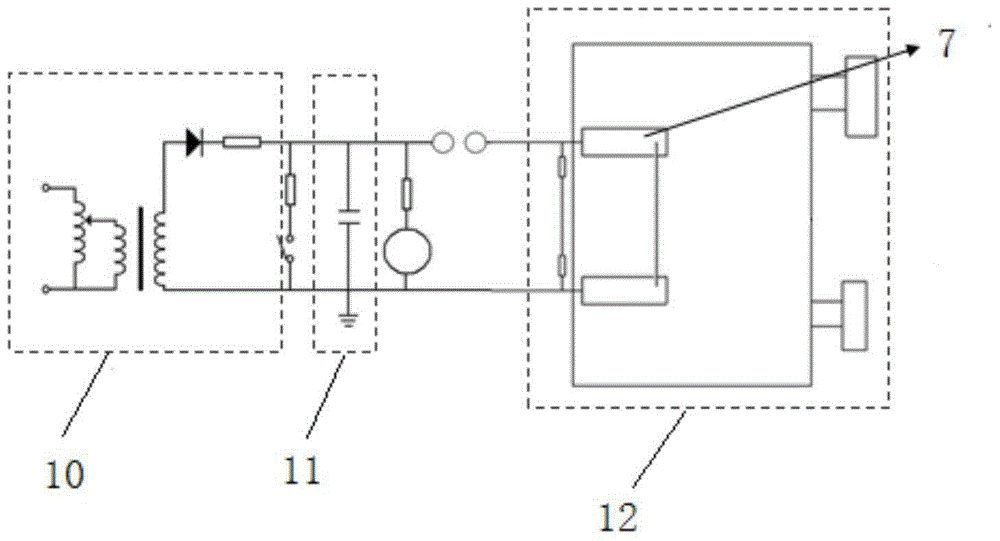

A nano-aluminum nitride and electric explosion technology is applied in the field of technology, which can solve the problems of large average particle size of nano-aluminum nitride, low gas medium quenching rate, and potential safety hazards, and achieves high cooling rate, low production cost, The effect of shortening the time for grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

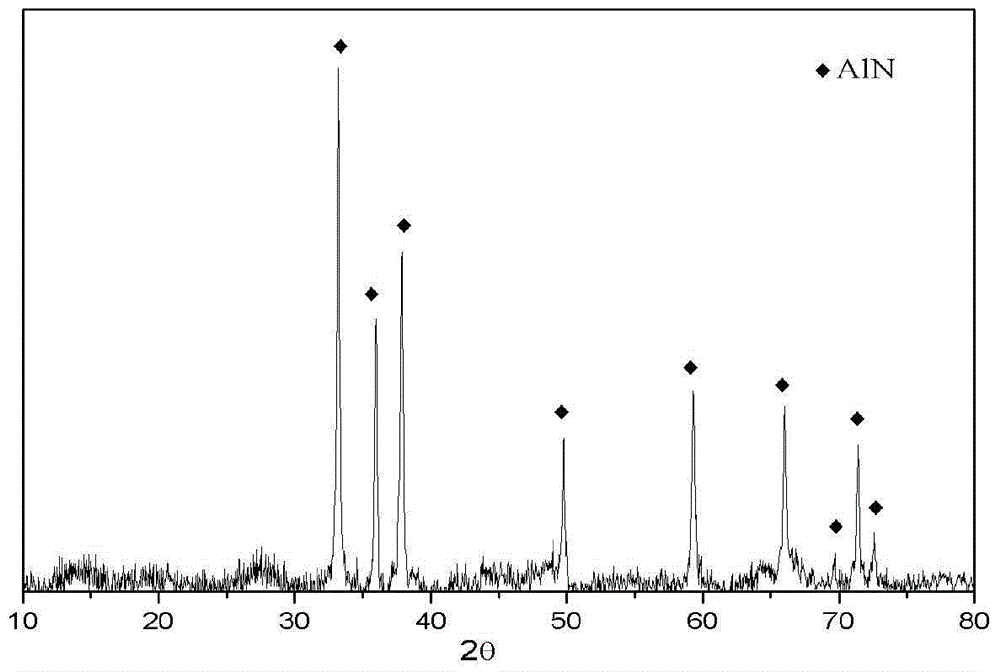

Embodiment 1

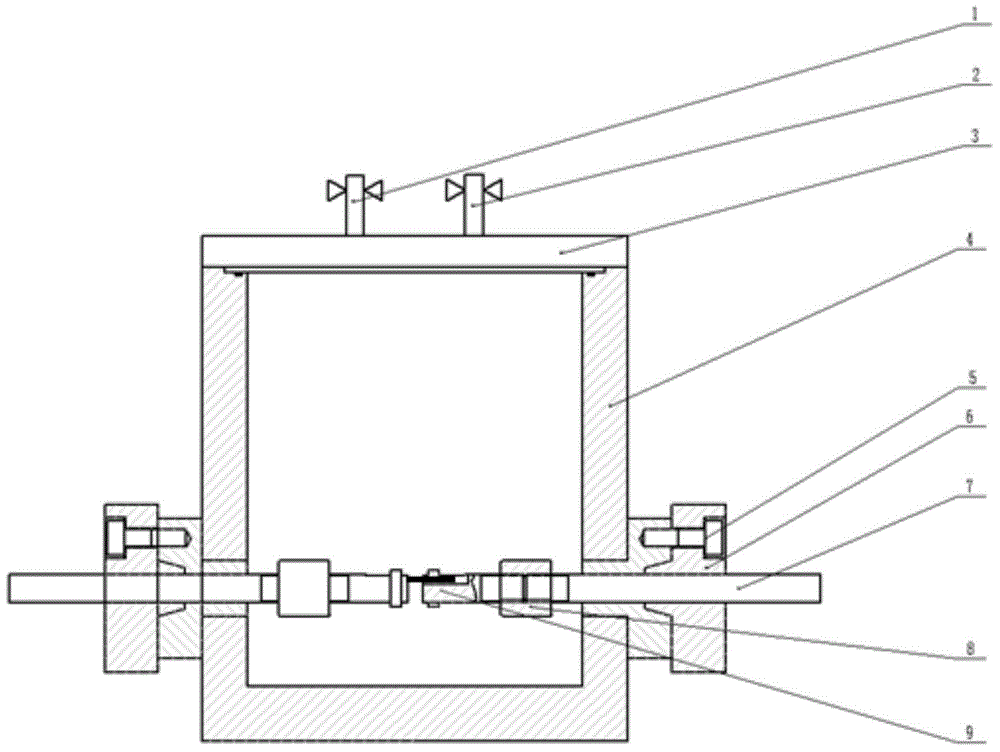

[0038] A method for preparing nano-aluminum nitride material by electric explosion, the specific steps of the method are as follows:

[0039] (1) Assembling and debugging the electric explosion system, so that the distance between the two electrodes on the electric explosion tank is 50mm ± 0.5mm; the aluminum wire with a purity of 99.99% is fixed between the electrodes by the electrode chuck;

[0040] (2) Clean the electric explosion tank with absolute ethanol, and dry it with a hot air blower; pour liquid nitrogen into the electric explosion tank so that it has not passed the pure copper electrode 5cm of the electric explosion tank, and seal the electric explosion tank by the tank cover;

[0041] (3) charge the high-voltage capacitor bank in the electric explosion system, make the voltage of the high-voltage capacitor bank reach 10kV, start the electric explosion system, and discharge;

[0042] (4) When the voltage of the high-voltage capacitor group is 0kV, open the electric e...

Embodiment 2

[0048] A method for preparing nano-aluminum nitride material by electric explosion, the specific steps of the method are as follows:

[0049] (1) Assembling and debugging the electric explosion system, so that the distance between the two electrodes on the electric explosion tank is 50mm ± 0.5mm; the aluminum wire with a purity of 99.99% is fixed between the electrodes by the electrode chuck;

[0050] (2) Clean the electric explosion tank with absolute ethanol, and dry it with a hot air blower; pour liquid nitrogen into the electric explosion tank, so that it has not passed the pure copper electrode 5.5cm of the electric explosion tank, and seal the electric explosion tank through the tank cover ;

[0051] (3) charge the high-voltage capacitor bank in the electric explosion system, make the voltage of the high-voltage capacitor bank reach 15kV, start the electric explosion system, and discharge;

[0052] (4) When the voltage of the high-voltage capacitor group is 0kV, open th...

Embodiment 3

[0058] A method for preparing nano-aluminum nitride material by electric explosion, the specific steps of the method are as follows:

[0059] (1) Assembling and debugging the electric explosion system, so that the distance between the two electrodes on the electric explosion tank is 50mm ± 0.5mm; the aluminum wire with a purity of 99.99% is fixed between the electrodes by the electrode chuck;

[0060] (2) Clean the electric explosion tank with absolute ethanol, and dry it with a hot air blower; pour liquid nitrogen into the electric explosion tank, so that it has not passed the pure copper electrode 5.5cm of the electric explosion tank, and seal the electric explosion tank through the tank cover ;

[0061] (3) charge the high-voltage capacitor bank in the electric explosion system, make the voltage of the high-voltage capacitor bank reach 19kV, start the electric explosion system, and discharge;

[0062] (4) When the voltage of the high-voltage capacitor group is 0kV, open th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com