Method using cobalt-based catalyst for preparation of carbon nanofiber by carbon dioxide hydrogenation

A cobalt-based catalyst, carbon nanofiber technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of high reaction energy consumption, high reaction conditions, and complex reaction steps. , to achieve the effect of high catalytic efficiency and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

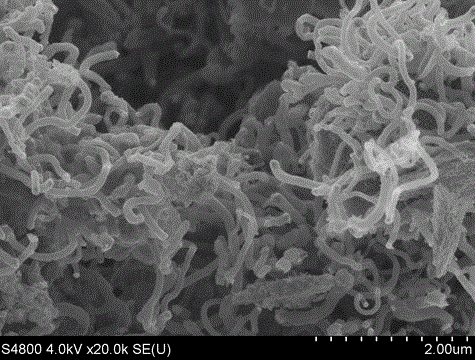

Image

Examples

preparation example Construction

[0020] K-Co-CeO 2 Catalyst preparation

[0021] Prepared by co-precipitation method, after cobalt nitrate solution and cerium nitrate solution are mixed uniformly, sodium hydroxide and sodium carbonate are used as precipitating agents, and the molar ratio of sodium hydroxide and sodium carbonate to sodium hydroxide and sodium carbonate is 1:1, and Flow titration, in this process, the pH value of the precipitation solution is controlled within the range of 10±0.1, stirred at room temperature for 4-5h, aged overnight, then filtered, washed repeatedly with distilled water until pH2 catalyst.

[0022] Impregnation of Co-CeO with a mass percent of Co of 1%-30% by potassium nitrate solution 2 Catalyst, dried at 80-100°C for 20-24h, then calcined in a muffle furnace at 500-800°C for 3-4h to obtain K-Co-CeO 2 catalyst.

[0023] 2%K-10%Co-CeO with 10% cobalt mass percentage and 2% potassium mass percentage 2 Catalyst as an example, the specific steps are as follows:

[0024] Weigh...

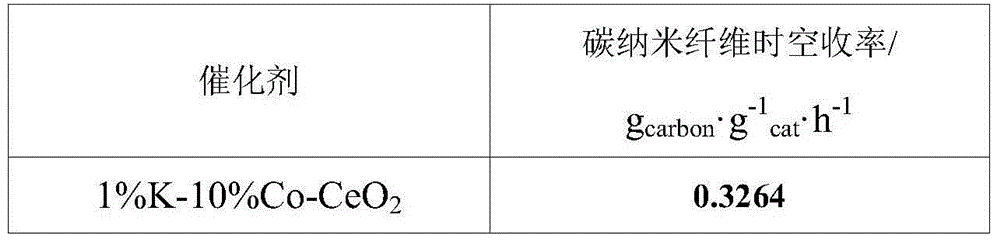

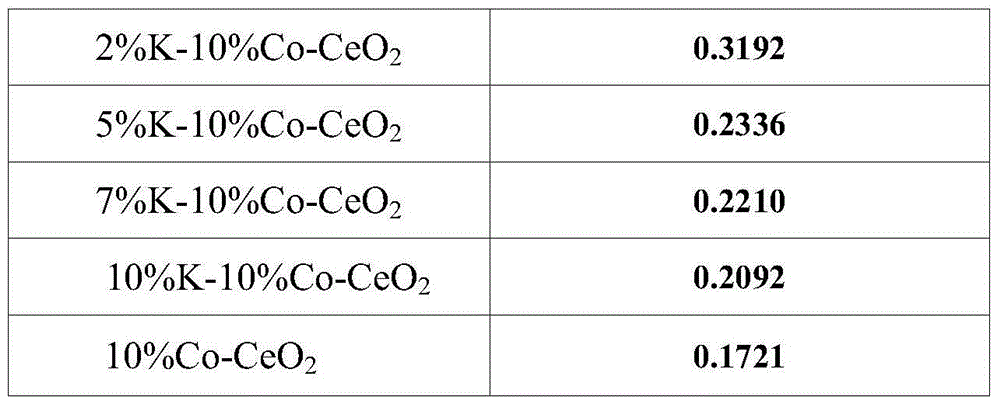

Embodiment 1

[0028] Using 60-100 mesh 1%K-10%Co-CeO 2 The catalyst is used as a catalyst for carbon dioxide hydrogenation to prepare carbon nanofibers. 1%K-10%Co-CeO 2 Catalyst and 60-100 mesh quartz sand are mixed evenly according to the weight ratio of 1:2, and the raw material gas is passed, and 1mg 1%K-10%Co-CeO 2 Catalyst meter, feed gas ventilation rate is 2ml / min, feed gas composition is 50vol.%CO 2 , 50vol.%H 2 ; Catalyzed reaction at 500°C for 2h to obtain carbon nanofibers.

Embodiment 2

[0030] Using 60-100 mesh 2%K-10%Co-CeO 2 The catalyst is used as a catalyst for carbon dioxide hydrogenation to prepare carbon nanofibers. 2%K-10%Co-CeO 2 Catalyst and 60-100 mesh quartz sand are mixed evenly according to the weight ratio of 1:2, and the raw material gas is passed, and 1mg 2%K-10%Co-CeO 2 Catalyst meter, feed gas ventilation rate is 2ml / min, feed gas composition is 50vol.%CO 2 , 50vol.%H 2 ; Catalyzed reaction at 500°C for 2h to obtain carbon nanofibers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com