Novel compound water treatment flocculant as well as preparation method and application thereof

A flocculant and water treatment technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of secondary pollution particles, aluminum and iron residues, difficult to settle and other problems, achieve less dosage, enhanced bridging effect, Water solubility enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: Preparation and flocculation precipitation

[0032] Preparation:

[0033] Step 1) Take 12kg of chitosan in an acid-resistant container, add 60kg of hydrochloric acid with a mass concentration of 2%, stir and heat up to 55°C, and heat to reflux for 1 hour to obtain a chitosan acid solution, add 35kg of bentonite, continue stirring, and heat to reflux React for 1 hour to obtain chitosan acid-soluble coated bentonite solution. After evaporating the above solution to remove water, dry it at 105°C to constant weight, crush it through a 80-mesh sieve, and obtain chitosan-loaded bentonite.

[0034] Step 2) Get 24kg of chitosan in an acid-resistant container, add 48kg of hydrochloric acid with a mass concentration of 1%, stir and heat up to 85°C to obtain a chitosan acid solution, and configure 25kg of glycidyltrimethylammonium chloride into The aqueous solution with a mass concentration of 75% is slowly added dropwise to the above-mentioned chitosan acid solutio...

Embodiment 2

[0039] Embodiment 2: Preparation and flocculation precipitation

[0040] Preparation:

[0041] Step 1) Take 16kg of chitosan in an acid-resistant container, add 64kg of hydrochloric acid with a mass concentration of 2%, stir and heat up to 60°C, and heat to reflux for 0.8 hours to obtain a chitosan acid solution, add 28kg of bentonite, continue stirring, and heat to reflux React for 1 hour to obtain a chitosan acid-soluble coated bentonite solution. After evaporating the above solution to remove water, dry it to a constant weight at 105° C. and grind it through a 100-mesh sieve to obtain chitosan-loaded bentonite.

[0042] Step 2) Get 32kg of chitosan in an acid-resistant container, add 32kg of hydrochloric acid with a mass concentration of 1%, stir and heat up to 90°C to obtain a chitosan acid solution, and configure 18kg of glycidyltrimethylammonium chloride into An aqueous solution with a mass concentration of 80% is slowly added dropwise to the above-mentioned chitosan ac...

Embodiment 3

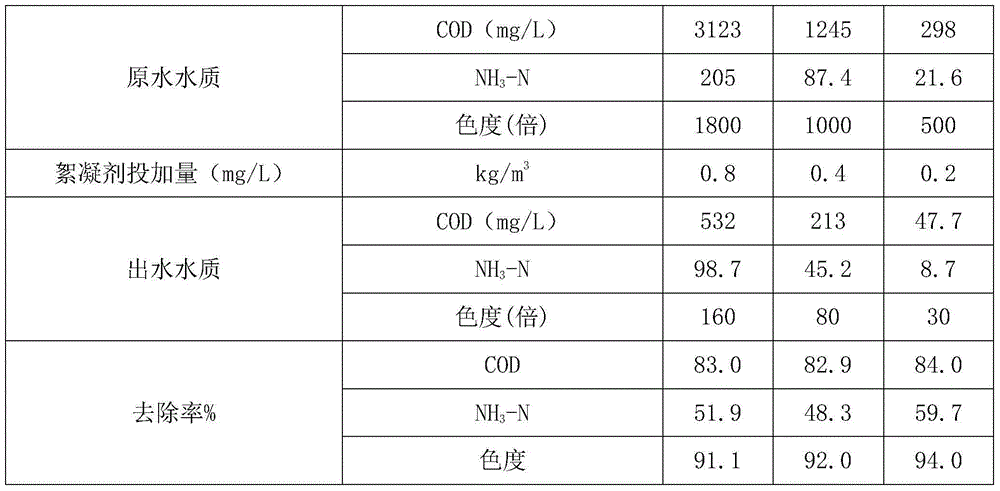

[0048] Embodiment 3: comparative experiment

[0049]Take the novel composite water treatment flocculant prepared in Example 1 as the group of the present invention, and a certain commercially available water treatment flocculant as the control group. The main components of this commercially available water treatment flocculant are ferric chloride, aluminum chloride, zinc sulfate , magnesium sulfate. The two groups of flocculants were applied to a certain municipal sewage. The dosing method was to directly add the flocculant to the sewage to be treated. The stirring was started during the dosing process, and the supernatant was taken after the reaction was completed and settled for 30 minutes. The results are as follows:

[0050]

[0051] It can be seen that, under the premise of the same water quality and the same dosage, the present invention has a better purification effect on municipal sewage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com