The preparation method of diphenhydramine

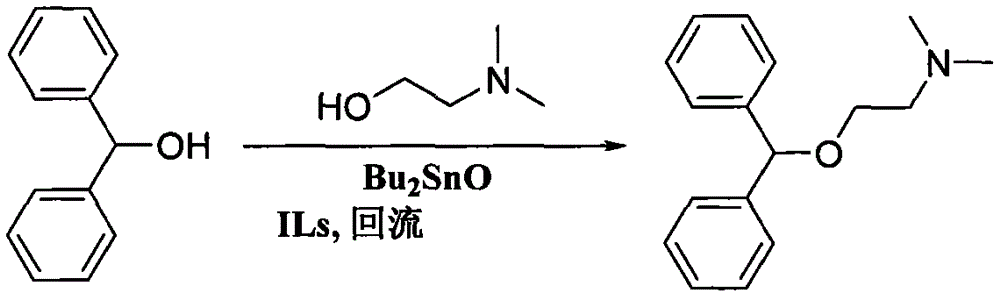

A technology of diphenhydramine and benzhydryl alcohol, applied in the field of preparation of diphenhydramine, can solve the problems of high production cost, inability to recycle toluenesulfonic acid, etc., and achieves easy operation, easy industrial production and high product yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

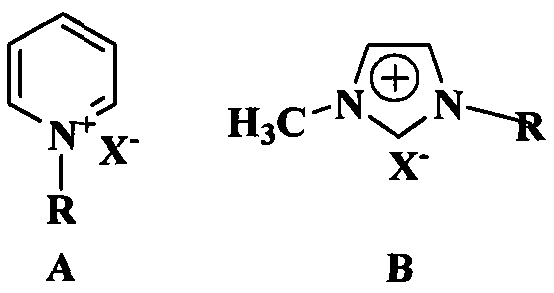

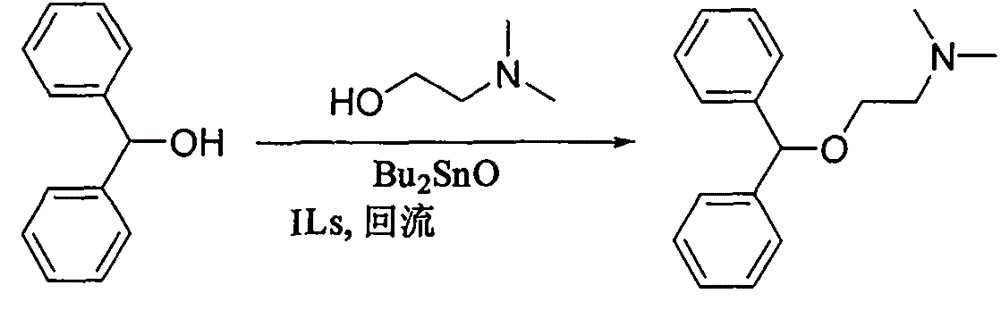

[0024] Add 36.8 grams (0.2mol) of diphenylmethanol, 26.7 grams (0.3mol) of dimethylaminoethanol, 2.9 grams (accounting for 8% of the mass of diphenylmethanol) of dibutyltin oxide and ionic liquid N bromide in a 250mL one-mouth bottle - 1.1 grams of n-propylpyridine (accounting for 3% of the mass of diphenylmethanol), the reaction mixture was stirred and reacted under reflux. The progress of the reaction was detected by gas chromatography. After reacting for 10 hours, the reaction was completed, and the excess dimethylaminoethanol (which can be recycled) was removed by distillation under reduced pressure, and then the temperature was raised to carry out distillation under reduced pressure to obtain 49.0 grams of diphenhydramine, with a yield of 96.0%, gas phase analysis 99.5% purity.

Embodiment 2

[0026] Add 36.8 grams (0.2mol) of diphenylmethanol, 26.7 grams (0.3mol) of dimethylaminoethanol, 1.1 grams (accounting for 3% of the mass of diphenylmethanol) of dibutyltin oxide and ionic liquid N bromide in a 250mL one-mouth bottle - 1.1 grams of n-propylpyridine (accounting for 3% of the mass of diphenylmethanol), the reaction mixture was stirred and reacted under reflux. The progress of the reaction was detected by gas chromatography. After reacting for 20h, the reaction was completed, and the excess dimethylaminoethanol (which can be recycled) was removed by distillation under reduced pressure, and then the temperature was increased to carry out distillation under reduced pressure to obtain 48.6 grams of diphenhydramine, with a yield of 95.1%, gas phase analysis 99.0% purity.

Embodiment 3

[0028] Add 36.8 grams (0.2mol) of diphenylmethanol, 35.6 grams (0.4mol) of dimethylaminoethanol, 3.68 grams (accounting for 10% of the mass of diphenylmethanol) of dibutyltin oxide and ionic liquid bromide 1 in a 250mL one-port bottle. - 1.8 g of methyl-3-ethylimidazolium salt (accounting for 5% of the mass of benzhydryl alcohol), and the reaction mixture was stirred and refluxed for reaction. The progress of the reaction was detected by gas chromatography. After reacting for 8 hours, the reaction was completed, and the excess dimethylaminoethanol (which can be recycled) was removed by distillation under reduced pressure, and then the temperature was raised to carry out distillation under reduced pressure to obtain 49.5 grams of diphenhydramine, with a yield of 97.0%, gas phase analysis 99.6% purity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com