Medium-low molecular weight rigid tackifying polymer, and preparation method and applications thereof

A low molecular weight, polymer technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of increasing the cost of crude oil extraction, poor temperature resistance, salt resistance, and failure to use normally, and achieve good compatibility properties, good salt resistance, and high solution apparent viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

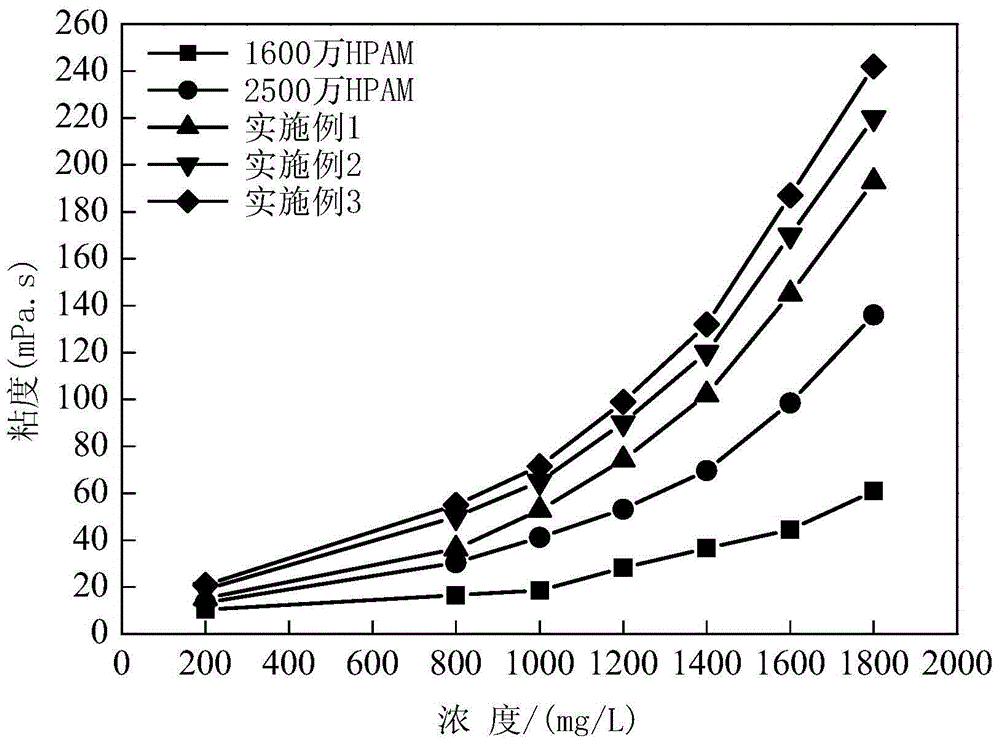

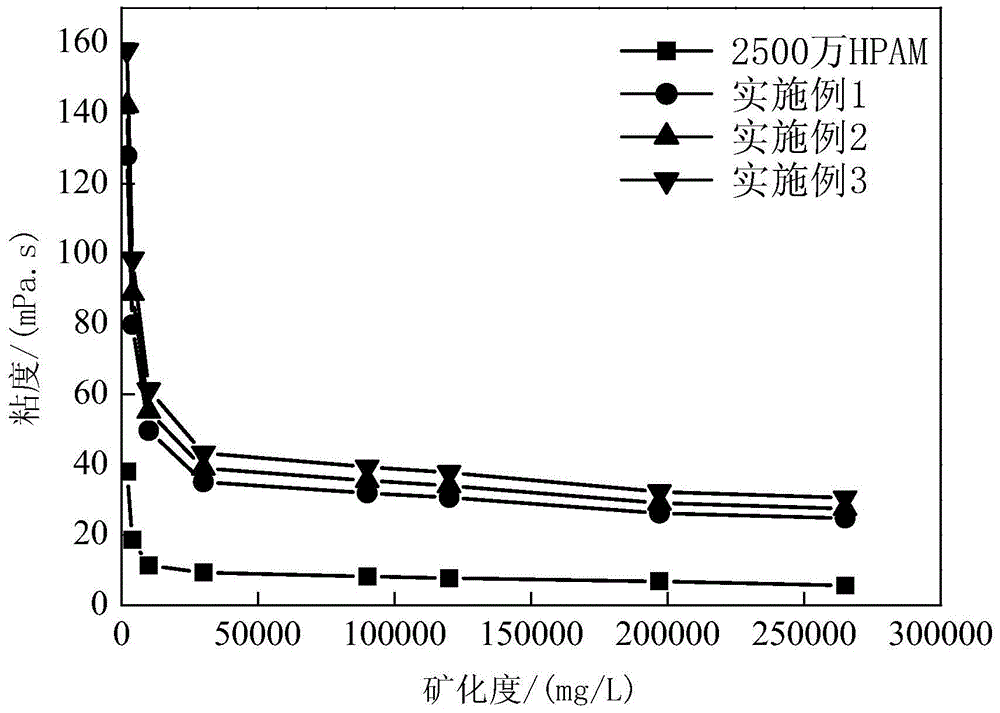

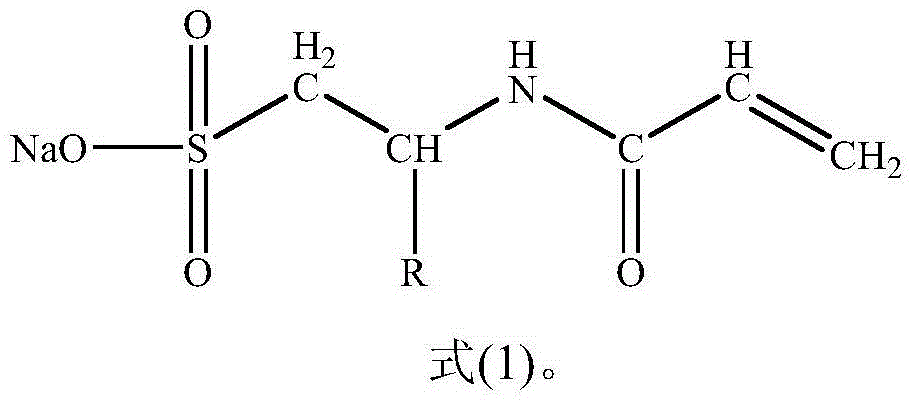

[0036] This embodiment provides a kind of medium and low molecular weight rigid tackifying polymer, wherein, the polymer is made of acrylic acid, acrylamide, 2-acrylamide-2-methylpropanesulfonic acid, 2-acrylamidoeicosylsulfonic acid Sodium acid four monomers are obtained by micellar radical polymerization.

[0037] The above-mentioned low and medium molecular weight rigid tackifying polymer is prepared through the following steps:

[0038] Put 0.02g sodium 2-acrylamidoeicosylsulfonate and 0.1g sodium dodecyl sulfate (SDS) in a 150mL beaker, add 23g distilled water, heat to 60°C, stir for 1-2 hours to reach a solution Transparent, completely dissolve 2-acrylamido eicosyl sodium sulfonate and sodium lauryl sulfate to obtain a uniform micellar solution;

[0039] Add 15g acrylamide (AM), 7g acrylic acid (AA), 5g 2-acrylamide-2-methylpropanesulfonic acid (AMPS) to 50g distilled water again, then add 7g anhydrous sodium carbonate (Na 2 CO 3 ), the pH value of the solution is adj...

Embodiment 2

[0043] This embodiment provides a kind of medium and low molecular weight rigid tackifying polymer, wherein, the polymer is made of acrylic acid, acrylamide, 2-acrylamide-2-methylpropanesulfonic acid, 2-acrylamidoeicosylsulfonic acid Sodium acid four monomers are obtained by micellar radical polymerization.

[0044] The above-mentioned low and medium molecular weight rigid tackifying polymer is prepared through the following steps:

[0045] Put 0.12g sodium 2-acrylamido eicosylsulfonate and 0.4g sodium dodecyl sulfate (SDS) in a 150mL beaker, add 36g distilled water, heat to 60°C, and stir for 2-3 hours to reach a solution Transparent, completely dissolve 2-acrylamido eicosyl sodium sulfonate and sodium lauryl sulfate to obtain a uniform micellar solution;

[0046] Add 15g acrylamide (AM), 7g acrylic acid (AA), 5g 2-acrylamide-2-methylpropanesulfonic acid (AMPS) to 37g distilled water again, then add 7g anhydrous sodium carbonate (Na 2 CO 3 ), the pH value of the solution i...

Embodiment 3

[0050] This embodiment provides a kind of medium and low molecular weight rigid tackifying polymer, wherein, the polymer is made of acrylic acid, acrylamide, 2-acrylamide-2-methylpropanesulfonic acid, 2-acrylamidoeicosylsulfonic acid Sodium acid four monomers are obtained by micellar radical polymerization.

[0051] The above-mentioned low and medium molecular weight rigid tackifying polymer is prepared through the following steps:

[0052] Put 1.2g sodium 2-acrylamidoeicosylsulfonate and 0.4g sodium dodecyl sulfate (SDS) in a 150mL beaker, add 36g distilled water, heat to 60°C, and stir for 2-3 hours to reach a solution Transparent, completely dissolve 2-acrylamido eicosyl sodium sulfonate and sodium lauryl sulfate to obtain a uniform micellar solution;

[0053] Add 15g acrylamide (AM), 7g acrylic acid (AA), 5g 2-acrylamide-2-methylpropanesulfonic acid (AMPS) to 37g distilled water again, then add 9g anhydrous sodium carbonate (Na 2 CO 3 ), the pH value of the solution is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com