Purifying method of crude polyaryletherketone product

A technology of polyaryletherketone and purification method, which is applied in the field of purification of polymer materials, can solve the problems of large amounts of waste liquid, large environmental impact, and high equipment requirements, and achieves reduced post-processing costs, simple and easy operation, and guaranteed The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

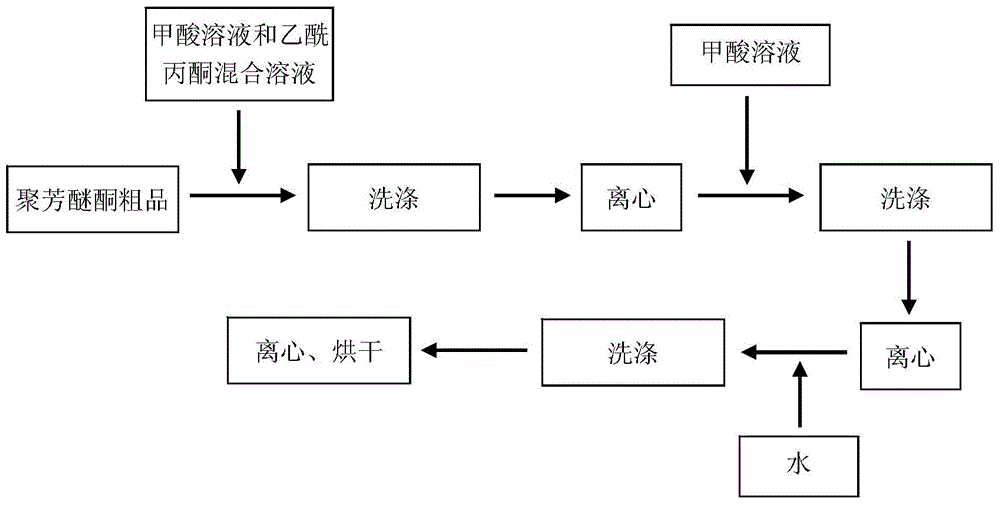

Method used

Image

Examples

Embodiment 1

[0027] Put 60kg of crude polyaryletherketone into the first stirred tank, and then add 600kg of a mixed solution of formic acid aqueous solution and acetylacetone, wherein the mass ratio of formic acid aqueous solution to acetylacetone is 4.2:1, the concentration of formic acid aqueous solution is 80%, and the temperature is raised to 100°C , sealed, stirred and refluxed for 10 hours, removed most of the solution by centrifugation, put the material in the second stirred tank, stirred and washed it with 1200 kg of 60% formic acid aqueous solution at room temperature for 2 hours, centrifuged, and put the material in the third stirred tank with 600 kg of water at room temperature Wash for 4 hours, centrifuge, and dry in a double-cone dryer at 140°C for 10 hours at normal pressure, and then dry at -0.1MPa for 3 hours. After testing, there is no organic solvent residue. The catalyst metal ion residue in polyaryletherketone is 19ppm, and the moisture content is 0.2 %.

Embodiment 2

[0029] Put 60kg of crude polyaryletherketone into the first stirred tank, and then add 1200kg of a mixed solution of formic acid aqueous solution and acetylacetone, wherein the mass ratio of formic acid aqueous solution to acetylacetone is 3.8:1, the concentration of formic acid aqueous solution is 95%, and the temperature is raised to 105°C , sealed, stirred and refluxed for 8 hours, removed most of the solution by centrifugation, put the material in the second stirred tank, stirred and washed it with 600 kg of 75% formic acid aqueous solution at room temperature for 4 hours, centrifuged, and the material was placed in the third stirred tank with 1200 kg of water at room temperature Wash for 4 hours, centrifuge, dry in a double-cone dryer at 130°C for 10 hours, and then dry at negative pressure -0.085MPa for 4 hours. After testing, there is no organic solvent residue. The catalyst metal ion residue in polyaryletherketone is 13ppm, and the moisture content is 0.3 %.

Embodiment 3

[0031] Put 60kg of crude polyaryletherketone into the first stirred tank, and then add 1100kg of a mixed solution of formic acid aqueous solution and acetylacetone, wherein the mass ratio of formic acid aqueous solution to acetylacetone is 4:1, the concentration of formic acid aqueous solution is 88%, and the temperature is raised to 104°C , sealed, stirred and refluxed for 9 hours, removed most of the solution by centrifugation, put the material in the second stirred tank, stirred and washed with 1000 kg of 68% formic acid aqueous solution at room temperature for 3 hours, centrifuged, and used 1000 kg of water at room temperature in the third stirred tank. Wash for 3 hours, centrifuge, dry in a double-cone dryer at 140°C for 8 hours, and then dry for 3 hours under negative pressure at -0.09MPa. After testing, there is no organic solvent residue. The catalyst metal ion residue in polyaryletherketone is 16ppm, and the moisture content is 0.4 %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com