Electronic equipment casing material and preparation method thereof

A shell material and technology for electronic equipment, applied in the field of shell materials of electronic equipment and their preparation, can solve the problems of heavy shell material, poor temperature resistance and flame retardancy, and high shrinkage rate, and achieve high melt flow index and flame retardant. Stable performance and low shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

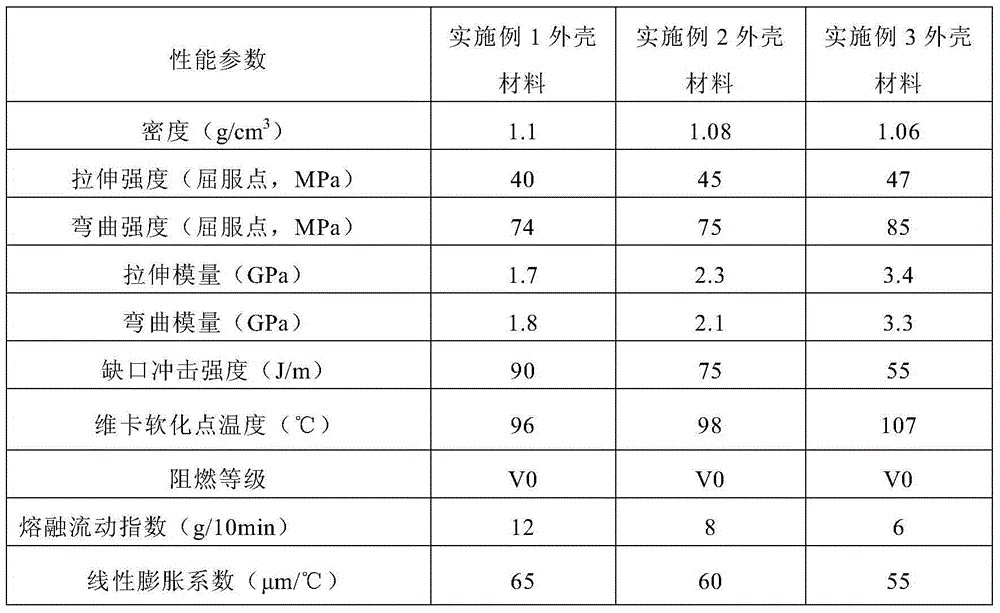

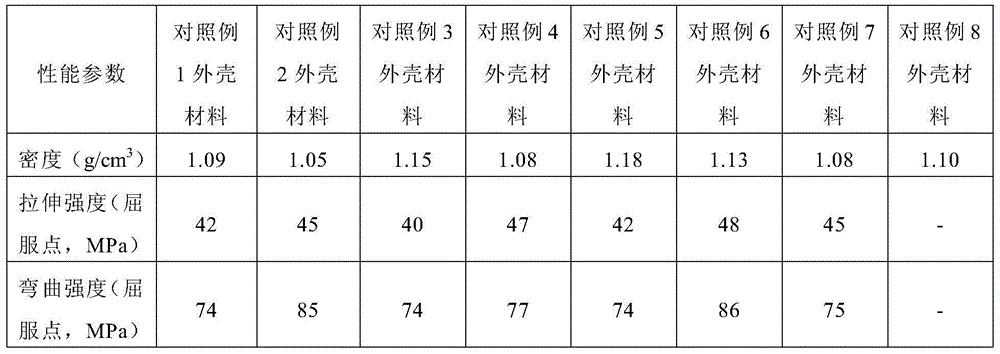

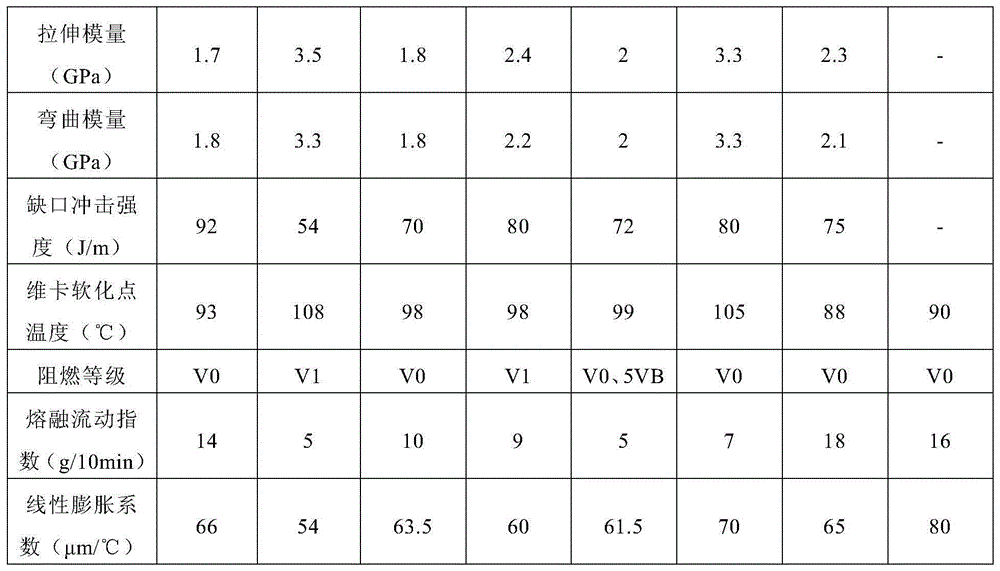

Examples

Embodiment 1

[0037] The shell material of this embodiment is made of the following raw material components in parts by weight: 30 parts of polyphenylene ether, 70 parts of high-impact polystyrene, 8 parts of decabromodiphenylethane, 1.5 parts of antimony trioxide, bromo 0.5 part of triazine, 3 parts of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 0.6 part of calcium stearate, 0.4 part of polyethylene wax, carbon black powder 1 serving.

[0038] The preparation method of the shell material is:

[0039] Add 30 parts of polyphenylene ether, 70 parts of high-impact polystyrene, 0.6 part of calcium stearate and 0.4 part of polyethylene wax into a high-speed mixer, stir and mix to obtain a premix.

[0040] Add 8 parts of decabromodiphenylethane, 1.5 parts of antimony trioxide, 0.5 parts of bromotriazine, 3 parts of tetrakis[β-(3,5-di-tert-butyl-4-hydroxy Phenyl) propionate] pentaerythritol ester and 1 part of carbon black powder, stir and mix to prepare a m...

Embodiment 2

[0044] The shell material of this embodiment is made of the following raw material components by weight: 55 parts of polyphenylene ether, 60 parts of high-impact polystyrene, 4 parts of triphenyl phosphate, bisphenol A-bis (diphenyl phosphate ) 6 parts, 2 parts of decabromodiphenylethane, 3 parts of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, β-(3,5-di 1 part of tert-butyl-4-hydroxyphenyl) n-octadecyl propionate, 1.5 parts of calcium stearate, 0.5 parts of polyethylene wax, and 2 parts of carbon black powder.

[0045] The preparation method of the shell material is:

[0046] Add 55 parts of polyphenylene ether, 60 parts of high-impact polystyrene, 1.5 parts of calcium stearate and 0.5 parts of polyethylene wax into a high-speed mixer, stir and mix to obtain a premix.

[0047] Add 4 parts of triphenyl phosphate, 6 parts of bisphenol A-bis(diphenyl phosphate), 2 parts of decabromodiphenylethane, 3 parts of tetrakis[β-(3,5- Di-tert-butyl-4...

Embodiment 3

[0051] The shell material of this embodiment is made of the following raw material components by weight: 70 parts of polyphenylene ether, 40 parts of high-impact polystyrene, 5 parts of triphenyl phosphate, bisphenol A-bis (diphenyl phosphate ) 6 parts, 4 parts of decabromodiphenylethane, tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] 3 parts of pentaerythritol ester, β-(3,5-di 1 part of n-octadecyl alcohol ester of tert-butyl-4-hydroxyphenyl) propionate, 1 part of tris[2.4-di-tert-butylphenyl] phosphite, 1.8 parts of calcium stearate, 1.2 parts of polyethylene wax , 2 parts of charcoal black powder.

[0052] The preparation method of the shell material is:

[0053] Add 70 parts of polyphenylene ether, 40 parts of high-impact polystyrene, 1.8 parts of calcium stearate and 1.2 parts of polyethylene wax into a high-speed mixer, stir and mix to obtain a premix.

[0054] Add 5 parts of triphenyl phosphate, 6 parts of bisphenol A-bis(diphenyl phosphate), 4 parts of d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com