Comprehensive treating agent for water injection well and preparation method of comprehensive treating agent

A comprehensive treatment agent, water injection well technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc. The effect of safe transportation and strong wax removal and anti-wax performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 85% compound organic solvent, 2% EVA220 (molecular weight is about 8500), 3% mixture of AR-36 and Tween-80 (mass ratio is 2:1), 10% methanol; sterilizing and antiscaling parts: 90% water , a mixture of 4% amino trimethylene phosphoric acid and polyaspartic acid (mass ratio is 1:1), a mixture of 5% O-30 and Span-65 (mass ratio is 3:1), 1% A mixture of dodecyldimethylbenzyl ammonium chloride and isothiazolinone (mass ratio 1:2).

[0019]Add xylene, cyclohexane, and petroleum ether into the container at a volume ratio of 3:1:4, and stir evenly to obtain a composite solvent. Subsequently, first add methanol in proportion to the composite organic solvent, and after stirring evenly, continue to add EVA220. After completely dissolving at 45°C, add a non-ionic surfactant and stir evenly to obtain the wax-removing part. At the same time, add the compound bactericide and antiscalant into the water in sequence, and after stirring evenly, continue to add emulsifier, and stir at a...

Embodiment 2

[0022] 80% composite organic solvent, 5% EVA230 (molecular weight around 9000), 5% mixture of AR-36 and Tween-80 (mass ratio is 2:1), 10% ethylene glycol monobutyl ether and ethanol mixture ( The mass ratio is 2:3); the sterilization and antiscaling part: 85% water, 3% mixture of amino trimethylene phosphoric acid and polyaspartic acid (mass ratio is 1:1), 10% O-30 and A mixture of Span-65 (mass ratio 3:1), a mixture of 2% dodecyldimethylbenzyl ammonium chloride and isothiazolinone (mass ratio 1:2). The specific preparation method is the same as above, wherein the stirring speed after adding the emulsifier is 80r / min; the stirring speed of the cleaning and anti-scaling parts mixed with the sterilization and anti-scaling parts is 300r / min.

Embodiment 3

[0024] 90% composite organic solvent, 2% EVA40W (molecular weight about 10000), 3% compound of AR-36 and Tween-80 (mass ratio 2:1), 5% isopropanol; bactericidal and anti-scaling parts: 87% water, 5% mixture of aminotrimethylene phosphoric acid and polyaspartic acid (mass ratio is 1:1), 7% mixture of O-30 and Span-65 (mass ratio is 3:1), 1% mixture of dodecyl dimethyl benzyl ammonium chloride and isothiazolinone (mass ratio 1:2). The specific preparation method is the same as above, wherein the stirring speed after adding the emulsifier is 100r / min; the stirring speed of the cleaning and anti-scaling parts mixed with the sterilization and anti-scaling parts is 500r / min.

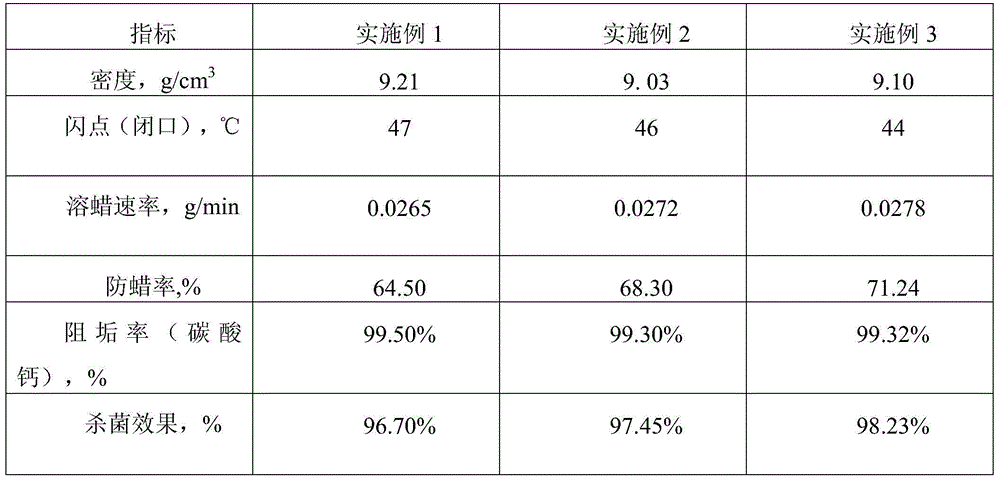

[0025] Implementation Effect:

[0026]

[0027] The present invention has reached following beneficial effect through above-mentioned embodiment:

[0028] 1. The wax melting rate is fast, reaching 0.0278g / min; the wax preventing rate is high, 71.24%;

[0029] 2. The scale inhibition effect on calcium car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com