Preparation method of high-strength graphene fibers

A high-strength graphite and graphene technology, applied in the chemical characteristics of fibers, textiles and papermaking, chemical post-processing of rayon, etc., can solve the problems of low strength, uneven structure, and difficulty of graphene fibers, and achieve excellent mechanical properties, Simple operation method and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

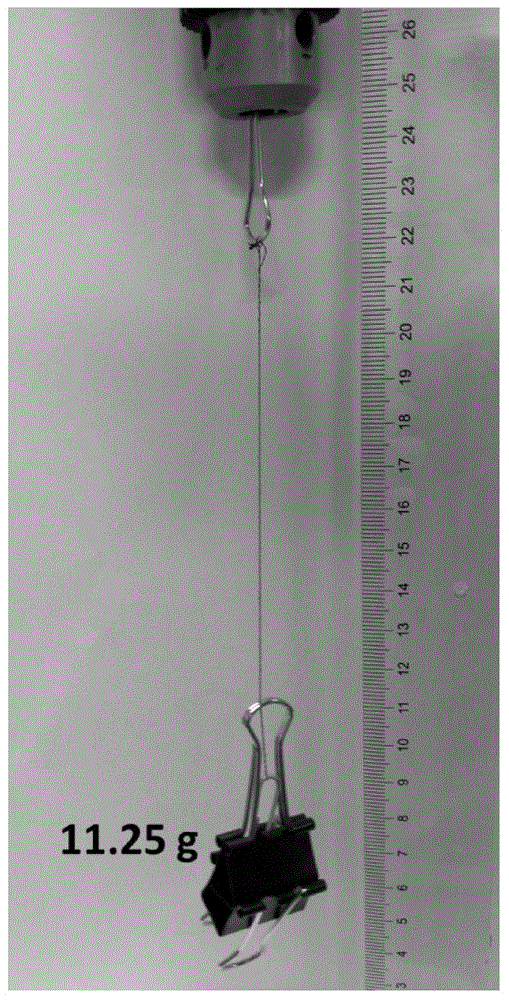

[0031] (1) At room temperature, weigh 200 mg of graphite oxide prepared by the improved Hummers method and place it in a 100 mL beaker, then add 20 mL of deionized water to make a dispersion with a concentration of 10 mg / mL, and then place the beaker into ultrasound Treat the graphite oxide in the pool for 3 hours to peel off the graphite oxide into graphene oxide to obtain 20 mL of a uniformly dispersed graphene oxide solution, then add 100 mg of sodium polyacrylate, and magnetically stir for 24 hours to form a graphene oxide / sodium polyacrylate gel-like spinning stock solution;

[0032] (2) Put the graphene oxide / sodium polyacrylate gel-like spinning stock solution into a 20mL syringe connected with a 500μm polytetrafluoroethylene microtube, and install it on a pusher with a pushing speed of 5mL / h. The graphene oxide / sodium polyacrylate gel is extruded orderly through the microtubes into a petri dish containing 95% alcohol by volume, and placed for 0.5h, then taken out and dried...

Embodiment 2

[0036] (1) At room temperature, weigh 200 mg of graphite oxide prepared by the improved Hummers method and place it in a 100 mL beaker, then add 20 mL of deionized water to make a dispersion with a concentration of 10 mg / mL, and then place the beaker into ultrasound Treat the graphite oxide in the pool for 3 hours to peel off the graphite oxide into graphene oxide to obtain 20 mL of a uniformly dispersed graphene oxide solution, then add 200 mg of sodium polyacrylate, and magnetically stir for 24 hours to form a graphene oxide / sodium polyacrylate gel-like spinning stock solution;

[0037] (2) Put the graphene oxide / sodium polyacrylate gel-like spinning stock solution into a 20mL syringe connected with a 500μm polytetrafluoroethylene microtube, and install it on a pusher with a pushing speed of 5mL / h. The graphene oxide / sodium polyacrylate gel is extruded orderly through the microtubes into a petri dish containing 95% alcohol by volume, and placed for 0.5h, then taken out and dried...

Embodiment 3

[0041] (1) At room temperature, weigh 200 mg of graphite oxide prepared by the improved Hummers method and place it in a 100 mL beaker, then add 20 mL of deionized water to make a dispersion with a concentration of 10 mg / mL, and then place the beaker into ultrasound Treat the graphite oxide in the pool for 3 hours to peel off the graphite oxide into graphene oxide to obtain 20 mL of a uniformly dispersed graphene oxide solution, then add 400 mg of sodium polyacrylate and magnetically stir for 24 hours to form a graphene oxide / sodium polyacrylate gel-like spinning stock solution;

[0042] (2) Put the graphene oxide / sodium polyacrylate gel-like spinning stock solution into a 20mL syringe connected with a 500μm polytetrafluoroethylene microtube, and install it on a pusher with a pushing speed of 5mL / h. The graphene oxide / sodium polyacrylate gel is extruded orderly through the microtubes into a petri dish containing 95% alcohol by volume, and placed for 0.5h, then taken out and dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com