Real-time online intelligent monitoring and demonstrating platform for structural load-response to change

A technology of structural load and demonstration platform, which is applied in the field of real-time online intelligent monitoring demonstration platform, can solve the problems of time-consuming and labor-consuming, limited engineering structure monitoring system, unobtainable load response of members and nodes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

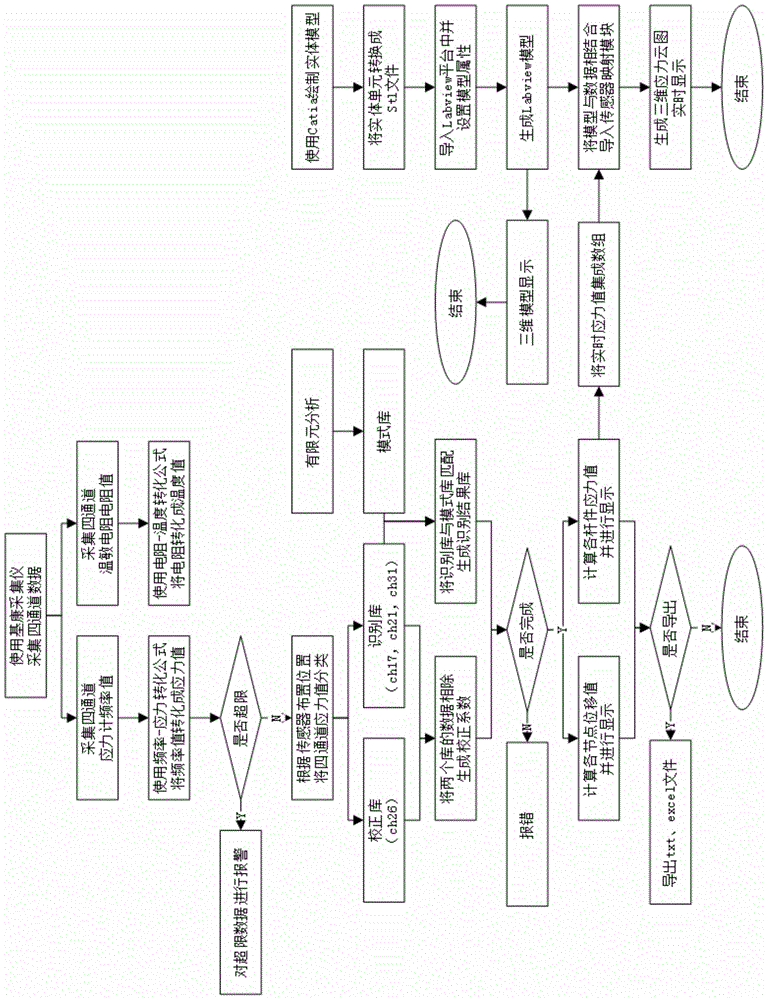

Method used

Image

Examples

Embodiment 1

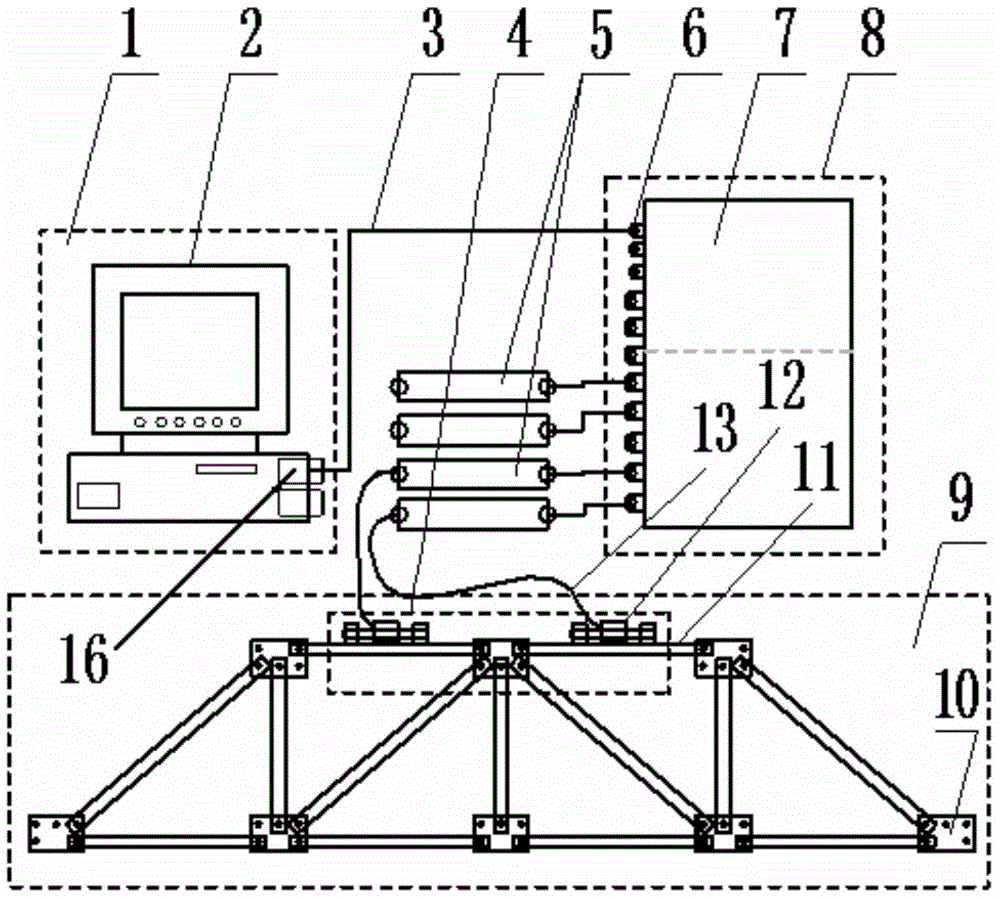

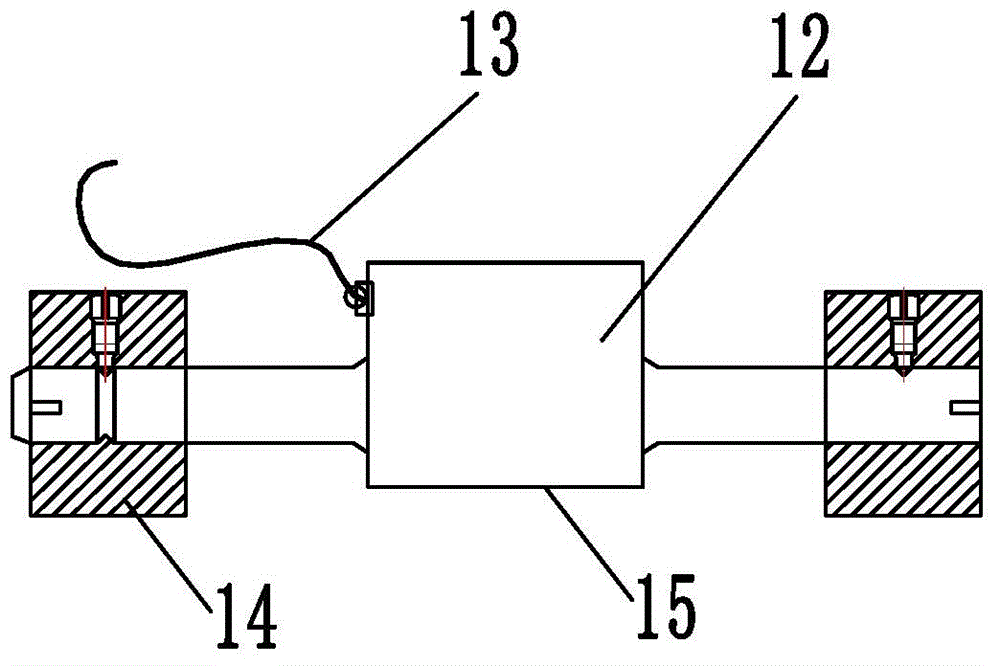

[0063] As shown in the figure, a real-time online intelligent monitoring demonstration platform for structural load-response changes, including software and hardware, is divided into sensor systems, data acquisition and processing systems, communication systems, and safety assessment systems. It consists of: communication system 1, computer Equipment 2, data line 3, sensor system 4, sensor terminal 5, channel serial port 6, data acquisition instrument 7, data acquisition and processing system 8, solid model of the engineering structure to be tested 9, member gusset plate 10, engineering structure connecting rod Part 11, a vibrating wire strain gauge 12, a communication cable 13, a sensor installation block 14, a sensor coil 15, and a USB port 16; a sensor system 4 is set on the solid model of the engineering structure to be measured 9, and the signal input port of the sensor terminal 5 One side is connected to the engineering structure connecting rod 11 by a communication cable...

Embodiment 2

[0065] As shown in the figure, the solid model 9 of the engineering structure to be tested is formed into a truss structure by connecting 40 engineering structure connecting rods 11 and 16 engineering structure rod gussets 10 through bolts, and the four rod gussets 10 correspond to Set four engineering structure connecting rods 11 to form a rectangle of 400mm*450mm, set engineering structure connecting rods 11 between two diagonal member gussets 10 in the rectangle to form a rectangular connection unit, and between three rod gussets 10 Correspondingly, three engineering structure connecting rods 11 are arranged to form a right-angled triangle connecting unit, and right-angled triangle connecting units are arranged on both sides of the two rectangular connecting units to form the isosceles trapezoidal side of the truss structure, and the isosceles trapezoidal side is composed of eight diagonal rods The gusset plate 10 and thirteen engineering structure connecting rods 11 are for...

Embodiment 3

[0069] As shown in the figure, the sensor system 4 is composed of: a vibrating wire strain gauge 12, a sensor mounting block 14, and a sensor coil 15; 0.12‰, waterproof performance and corrosion resistance meet the requirements of the relevant national standards GB / T, adapt to various engineering structures under the external conditions of gravity, wind, cold and heat, and monitor the strain and temperature changes of the structure for a long time in four seasons;

[0070] The data acquisition and processing system 8 is composed of: data acquisition equipment such as data acquisition instrument 7, data acquisition and processing system software;

[0071] Data line 3 adopts RS232 to USB data line;

[0072] The communication system 1 employs a computer device 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com