Multi-waveguide integrated resonance semiconductor laser

A technology integrating resonance and semiconductor, applied in the field of new semiconductor lasers, can solve the problems of narrow linewidth, high beam quality, high coherence, etc., and achieve the effect of improving energy density, high brightness and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

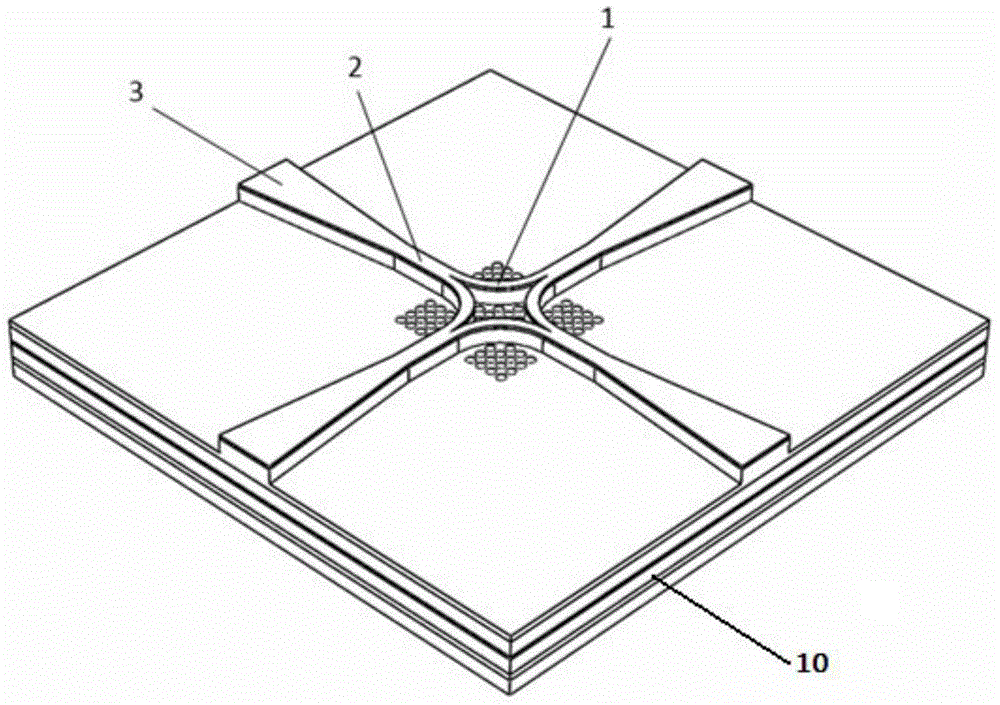

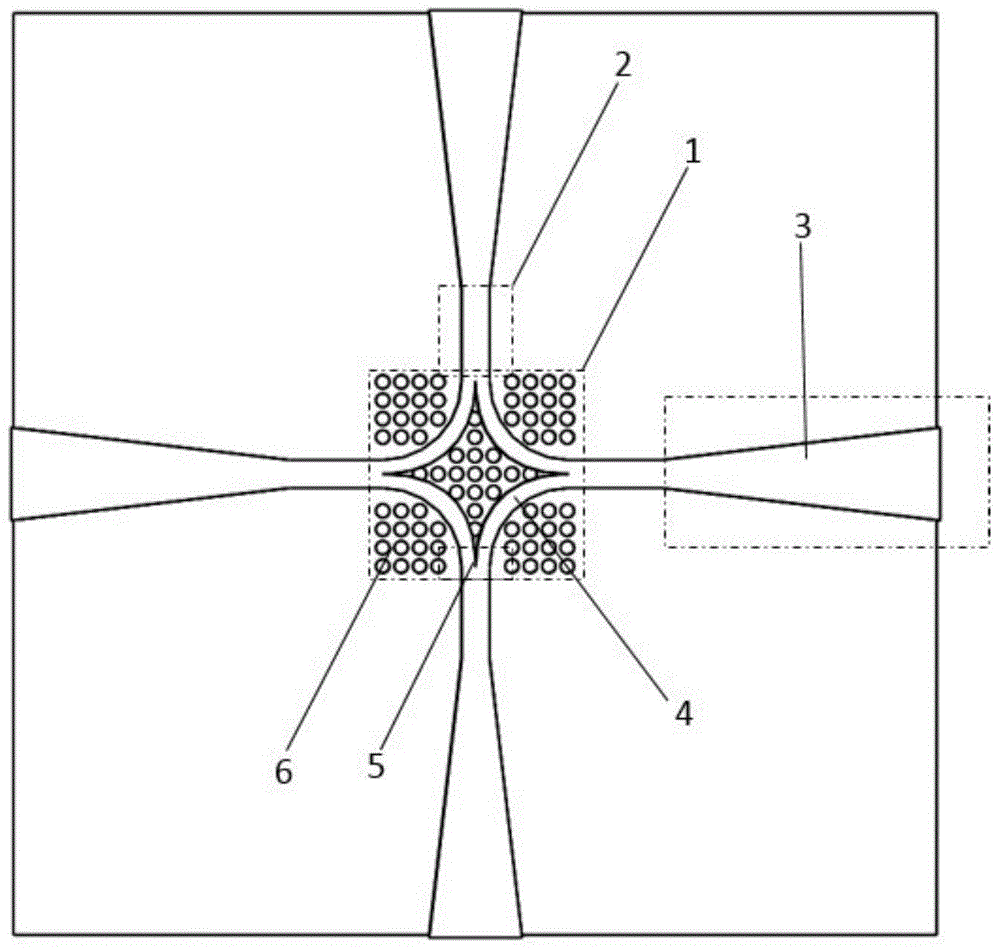

[0028] Such as figure 1 and figure 2 As shown, in this embodiment, on the designed and prepared semiconductor laser chip 10 with a wavelength of 980nm and an effective refractive index of 3.48 in this wavelength band, photonic bridge 1 is etched out at one time by photolithography and etching methods. , the mode stabilizer 2, and the ridge-shaped raised portion of the power amplifier 3. Then, the photonic crystal is further prepared downward on the lower mesa of the ridge by electron beam engraving. Among them, the specific size requirement of the photonic crystal is that the 980nm laser is within the photonic band gap of the photonic crystal, and the 980nm photons are not allowed to propagate in it; Shaped foot 88°. Then the usual semiconductor process is carried out, that is, evaporating oxide insulating layer, photolithography overlay electrode window, making metal electrode for ohmic contact, chip jointing, cavity surface coating and other processes. In this embodimen...

Embodiment 2

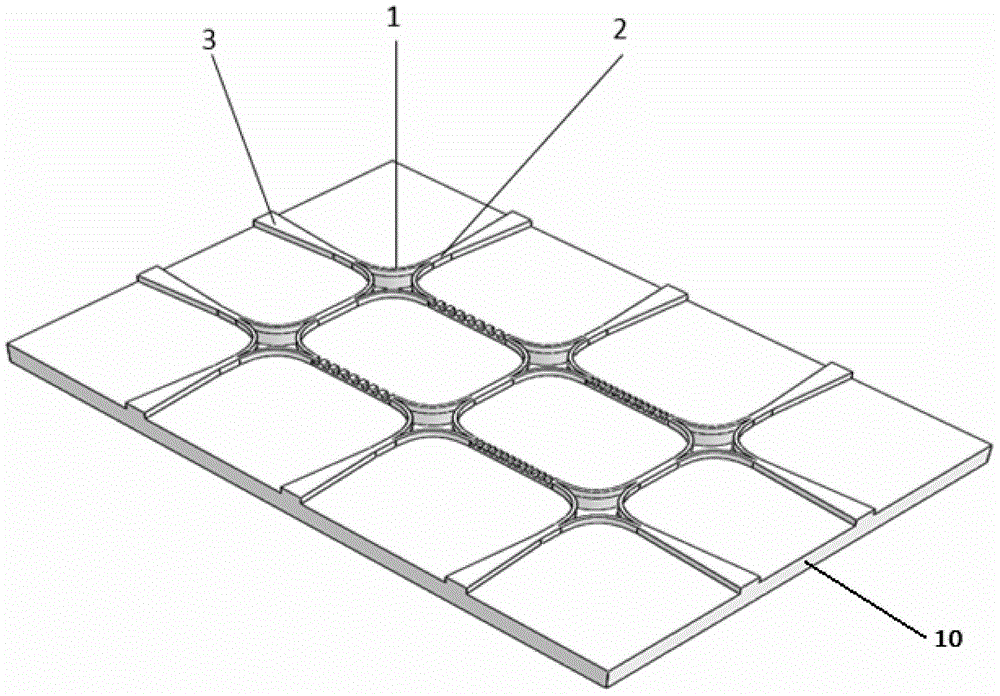

[0030] Such as image 3 and Figure 4 As shown, in this embodiment, on the semiconductor laser chip 10 that has been designed and prepared near the wavelength of 980nm and has an effective refractive index of 3.48 in this wavelength band, firstly, by photolithography or electron beam etching, the designed Position the grating structure in the mode stabilizer 2, in this embodiment, when the multi-waveguide integrated resonant semiconductor laser is designed to work at a single wavelength of 980nm, the period of the grating is 281.6nm; when the multi-waveguide integrated resonant semiconductor laser design wavelength is When the dual-wavelength 975nm and 985nm work, the grating structure is designed in two sizes, the grating period on the first grating 7 is 280nm, the grating period on the second grating 8 is 283nm, and the duty ratio is 0.5; it has a stable phase difference Dual-wavelength multi-waveguide integrated resonant semiconductor lasers can generate terahertz lasers b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com