A preparation method of roselle tobacco spice and its application in recombined tobacco leaves

A technology for tobacco spices and recombined tobacco leaves, which can be used in the preparation of tobacco, application, essential oils/flavors, etc. It can solve the problems of increased smoke tar, achieve increased smoke concentration, short production cycle, and large-scale industrial application transformation prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

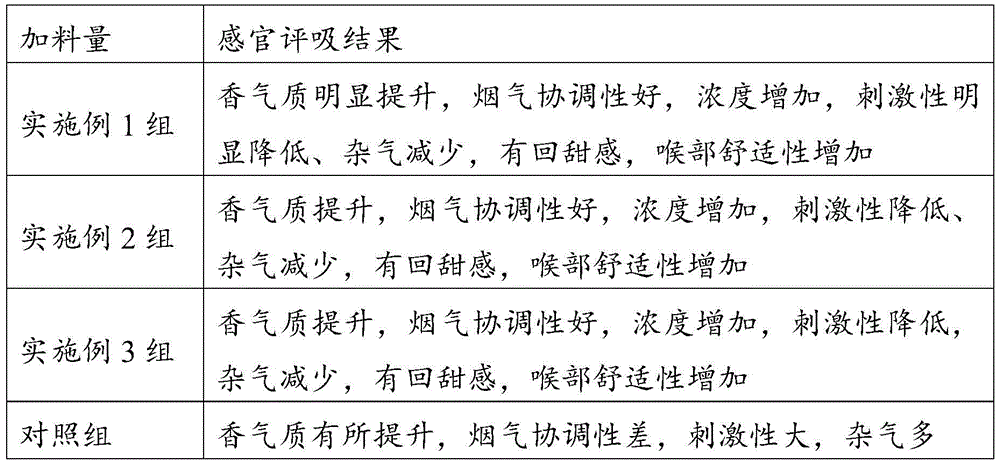

Examples

Embodiment 1

[0023] A preparation method of roselle tobacco spice, the steps are as follows:

[0024] 1) Add 20Kg of water to 1Kg of roselle calyx coarse powder, treat with 600w microwave for 5 minutes for cell wall extraction, then add 3g of cellulase, stir and incubate for 12 hours at pH 4 and temperature 35°C to obtain purple Red roselle enzyme hydrolyzate;

[0025] 2) Add 50 g of compound amino acids to the roselle enzymatic hydrolyzate, stir and mix well, add ammonia water to adjust the pH to 8, heat to reflux at 100°C (to inactivate the enzyme) to carry out Maillard reaction for 5 hours, after the reaction is completed, heat at 4°C Impurities were removed by centrifugation at 10,000 rpm, and the supernatant was concentrated to a purple-black extract with a relative density of 1.15 to obtain roselle tobacco flavor.

[0026] The compound amino acids are: proline, glutamic acid, serine, alanine, the weight ratio of which is 1:1:0.8:1.2.

Embodiment 2

[0028] A preparation method of roselle tobacco spice, the steps are as follows:

[0029] 1) Add 30Kg of water to 1Kg of roselle calyx coarse powder, 500w microwave treatment for 15 minutes for cell wall extraction, then add 1g of cellulase, and stir and incubate for 6 hours at a pH of 5 and a temperature of 40°C to obtain purple Red roselle enzyme hydrolyzate;

[0030] 2) Add 100 g of compound amino acids to the roselle enzymatic hydrolyzate, stir and mix well, add ammonia water to adjust the pH to 9, heat and reflux at 90°C (enzyme inactivation) to carry out Maillard reaction for 8 hours, after the reaction, centrifuge at room temperature Impurities are removed, and the supernatant is concentrated to a purple-black extract with a relative density of 1.2 to obtain roselle tobacco flavor.

[0031] The compound amino acid is: proline, glutamic acid, serine, alanine, and its weight ratio is =1:2:0.5:0.5.

Embodiment 3

[0033] A preparation method of roselle tobacco spice, the steps are as follows:

[0034] 1) Add 10Kg of water to 1Kg of roselle calyx coarse powder, treat with 800w microwave for 10 minutes for cell wall extraction, then add 2g of cellulase, stir and incubate for 24 hours at a pH of 4.5 and a temperature of 30°C to obtain purple Red roselle enzyme hydrolyzate;

[0035] 2) Add 20 g of compound amino acids to the roselle enzymatic hydrolyzate, stir and mix well, add ammonia water to adjust the pH to 9, heat and reflux at 120°C for Maillard reaction for 4 hours, centrifuge after the reaction, and concentrate the supernatant to a relative density The purple-black extract of 1.1 is used to obtain roselle tobacco spice.

[0036] The compound amino acid is: proline, glutamic acid, serine, alanine, and its weight ratio is =1:0.5:2:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com