SCR denitration system and method

A technology of SCR reactor and denitrification, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail through the accompanying drawings and specific embodiments below.

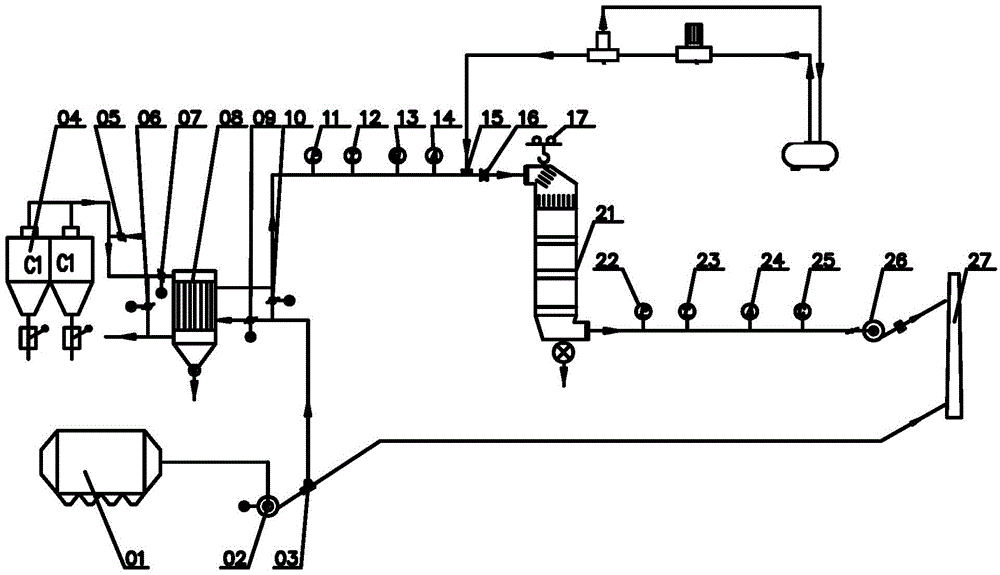

[0027] The invention provides a high-efficiency SCR denitrification system for a cement kiln system, such as figure 1As shown, including kiln tail dust collector 01, kiln tail fan 02, electric tee 03, kiln tail preheater 04, kiln tail flue gas cold air valve 05, high temperature regulating valve 06, 07, heat exchanger 08, SCR reaction Device 21, low temperature regulating valves 09,10. The kiln tail preheater 04 is connected to the smoke inlet of the high temperature area of the heat exchanger 08 through a flue, and the kiln tail dust collector 01 is connected to the smoke inlet of the low temperature area of the heat exchanger 08 through a flue, The passages of the high and low temperature flue gas are isolated from each other, and are used to respectively pass into the high and low temperature flue gas for heat exchange without mass transf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com