High-concentration printing ink waste liquid treatment and sludge dewatering integration method and high-concentration printing ink waste liquid treatment and sludge dewatering integration apparatus

A technology for waste liquid treatment and sludge dewatering, applied in chemical instruments and methods, dewatering/drying/concentrating sludge treatment, water/sewage multi-stage treatment, etc. Problems such as low dehydration efficiency, to achieve the effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

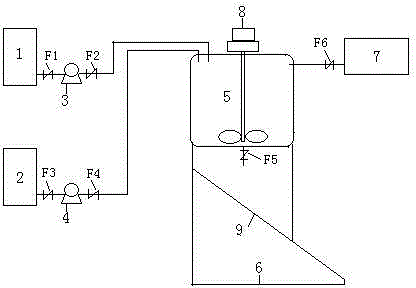

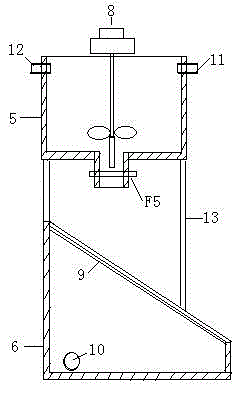

[0024] refer to figure 1 and figure 2 .

[0025] The present invention provides an integrated method and device for the treatment of high-concentration ink waste liquid and its sludge dehydration, which includes ink waste liquid storage tanks 1 and 2, a reaction solidification dehydrator 5, a solid-liquid separation screen 6 and an acid storage tank 7 four parts.

[0026] The water-based ink waste liquid storage tank 1 and the oily ink waste liquid storage tank 2 described therein are open cylinders, which are used to collect and store water-based ink waste liquid and oily ink waste liquid respectively; ink waste liquid storage tank and reaction curing There are sewage pipe connections between the dehydration tanks 5, and sewage pumps are respectively arranged on the sewage pipes; a mixer is arranged in the center of the reaction curing dehydration tank, the motor of the mixer is steplessly speed-regulated, and the lower part of the stirring shaft is in a spiral shape; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com