Phosphogypsum-based aluminium alloy-like decoration material and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

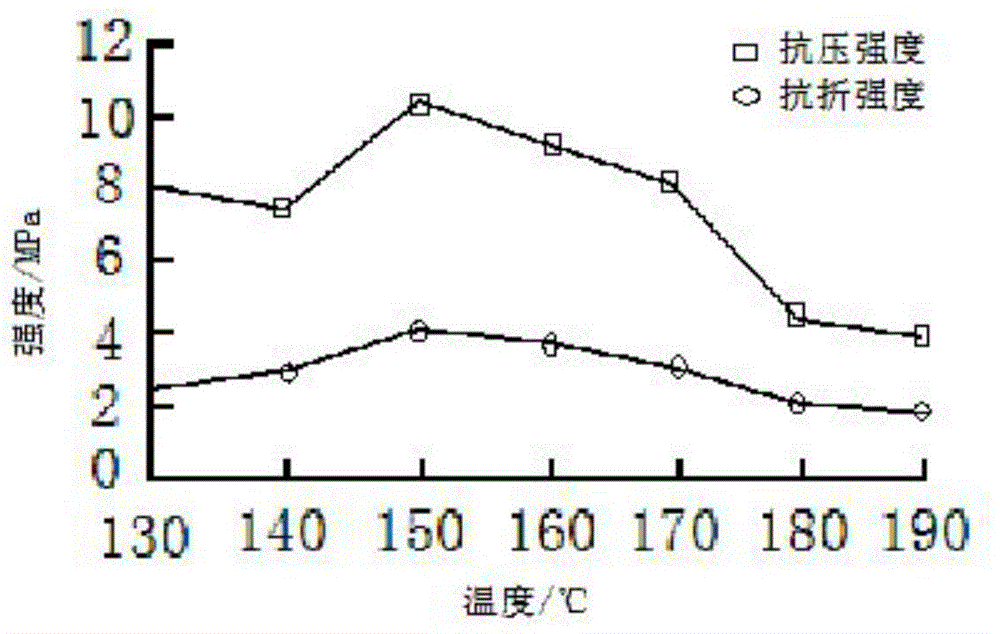

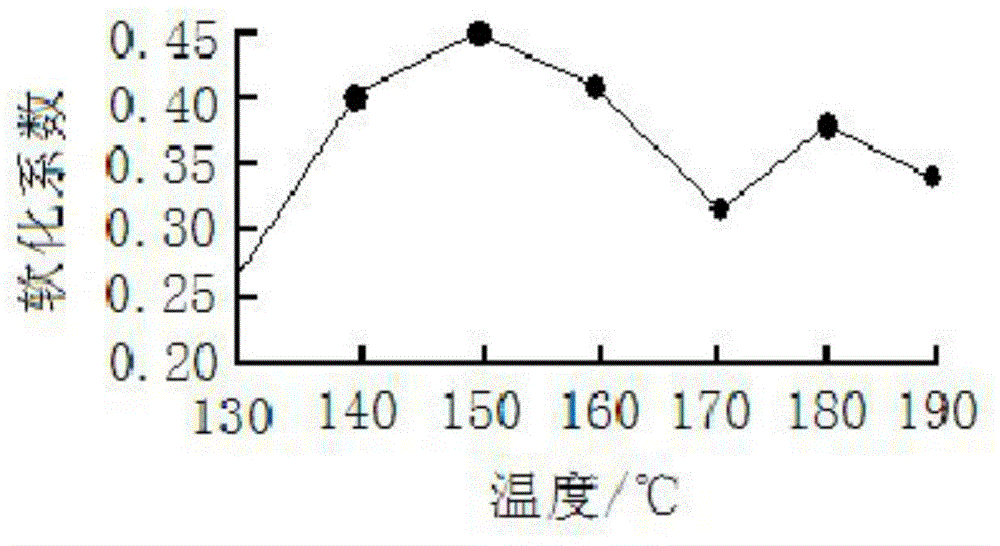

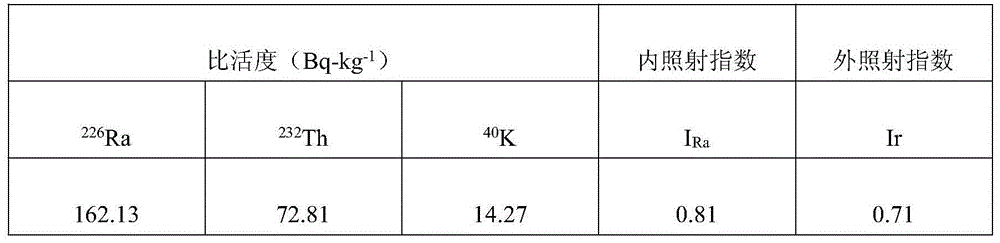

Embodiment 1

[0037] Formula: phosphogypsum 100kg, electrolytic yellow phosphorus slag 80kg, quicklime 4kg, montmorillonite 10kg, quartz sand 16kg, polyester resin 12kg.

[0038] Preparation:

[0039] (1) Ingredients: Take phosphogypsum and quicklime according to the mass ratio of 22:1 and neutralize them for 1 minute, put them into the mixer, add montmorillonite, quartz sand, polyester resin and stir for 36 seconds, then turn on the mixer and add electrolytic Continue to stir the yellow phosphorus slag for 80s to obtain the mixed material, then dry the mixed material until the free water is ≤1%, and put it into a ball mill for grinding for 50 minutes;

[0040] (2) Aging: aging the mixed material after ball milling in step (1) after calcining at a temperature of 120° C. for 1 hour, and the aging time is 32 hours;

[0041] (3) Forming: put the aged material into the vibration forming machine, and vibrate and form according to the required shape;

[0042] (4) Autoclave curing: After the vi...

Embodiment 2

[0048] Formula: phosphogypsum 170kg, electrolytic yellow phosphorus slag 110kg, quicklime 8kg.

[0049] Preparation:

[0050] (1) Ingredients: Take phosphogypsum and unslaked lime according to the mass ratio of 22:1 and neutralize them for 1 minute, put them into the mixer and stir for 36 seconds, then turn on the mixer, add electrolytic yellow phosphorus slag and continue to stir for 80 seconds to obtain the mixed material, then After drying the mixed material to free water ≤ 1%, put it into a ball mill for grinding for 52 minutes;

[0051] (2) Aging: aging the mixed material after ball milling in step (1) after calcining at a temperature of 140° C. for 1 hour, and the aging time is 36 hours;

[0052] (3) Forming: put the aged material into the vibration forming machine, and vibrate and form according to the required shape;

[0053] (4) Autoclave curing: After the vibration-formed material is naturally cured for 7 days, autoclave curing is carried out at a heating rate of 20...

Embodiment 3

[0059] Formula: phosphogypsum 120kg, electrolytic yellow phosphorus slag 90kg, quicklime 5kg, montmorillonite 10kg, quartz sand 16kg, polyester resin 12kg.

[0060] Preparation:

[0061] (1) Ingredients: Take phosphogypsum and quicklime according to the mass ratio of 22:1 and neutralize them for 1 minute, put them into the mixer, add montmorillonite, quartz sand, polyester resin and stir for 36 seconds, then turn on the mixer and add electrolytic Continue to stir the yellow phosphorus slag for 80s to obtain the mixed material, then dry the mixed material until the free water is ≤1%, and put it into a ball mill for grinding for 58 minutes;

[0062] (2) Aging: aging the mixed material after ball milling in step (1) after calcining at a temperature of 160° C. for 2 hours, and the aging time is 40 hours;

[0063] (3) Forming: put the aged material into the vibration forming machine, and vibrate and form according to the required shape;

[0064] (4) Autoclave curing: After the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com