High-strength thermoplastic starch composite material and preparation method thereof

A thermoplastic starch and composite material technology, applied in the field of composite materials, can solve the problems of low strength, affecting the application range, poor mechanical properties of thermoplastic starch materials, etc., and achieve the effect of improving willfulness, high strength and increasing plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

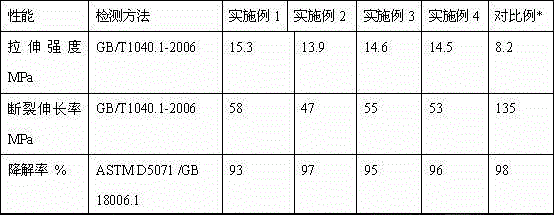

Examples

Embodiment 1

[0016] Embodiment 1: A high-strength thermoplastic starch composite material, including the following components in mass parts ratio: thermoplastic starch 30wt%, calcium carbonate 10wt%, hemicellulose 20wt%, vegetable protein 10wt%, polyethylene 25wt%, auxiliary agent 5wt %.

[0017] In this embodiment, the mesh number of the calcium carbonate is 80-300 mesh; the vegetable protein is a compound of soybean protein isolate and zein; Oxygen agent 1076 0.5wt%, polyethylene glycol 3wt%, silane coupling agent 1.5wt%; The hemicellulose is polygalactose glucomannose hemicellulose, and the aspect ratio of the hemicellulose is 3~15.

[0018] The preparation method of described a kind of high strength thermoplastic starch composite material, comprises the following steps:

[0019] a. Modification of calcium carbonate: put calcium carbonate and 1 / 3 mass of silane coupling agent in absolute ethanol, react at 90°C for 4h, then filter and dry;

[0020] b. Hemicellulose pretreatment: place...

Embodiment 2

[0024] Embodiment 2: A high-strength thermoplastic starch composite material, including the following components by mass ratio: thermoplastic starch 35wt%, calcium carbonate 5wt%, hemicellulose 30wt%, vegetable protein 5wt%, polyethylene 17wt%, auxiliary agent 8wt %.

[0025] In this embodiment, the mesh number of the calcium carbonate is 80-300 mesh; the vegetable protein is a compound of soybean protein isolate, pea protein, peanut protein, corn protein, and wheat protein; the auxiliary agent and its proportion The mass ratio of the composite material is 0.8wt% of antioxidant 1076, 5wt% of polyethylene glycol, and 2.2wt% of silane coupling agent; A compound of galactose-glucomannose hemicellulose, the aspect ratio of the hemicellulose is 3-15.

Embodiment 3

[0026] Embodiment 3: A high-strength thermoplastic starch composite material, including the following components by mass ratio: thermoplastic starch 27wt%, calcium carbonate 12wt%, hemicellulose 24wt%, vegetable protein 12wt%, polyethylene 21wt%, auxiliary agent 4wt %.

[0027] In the present embodiment, the mesh number of the calcium carbonate is 80-300 mesh; the vegetable protein is isolated soybean protein; , polyethylene glycol 2.5wt%, silane coupling agent 1.2wt%; the hemicellulose is polyxylan hemicellulose, and the aspect ratio of the hemicellulose is 3-15.

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com